FUEL AND EMISSION CONTROL SYSTEMS

F3

(FP, FS)

PRESSURE REGURATOR

FEATURES

REMOVAL/INSTALLATION .......................... F3-42

PRESSURE REGULATOR INSPECTION ....... F3-42

OUTLINE .............................................................. F3-3

PRC SOLENOID VALVE INSPECTION (FS) .. F3-43

OUTLINE OF CONSTRUCTION ....................... F3-3

FUEL PUMP UNIT INSPECTION .................... F3-44

FEATURES ........................................................ F3-3

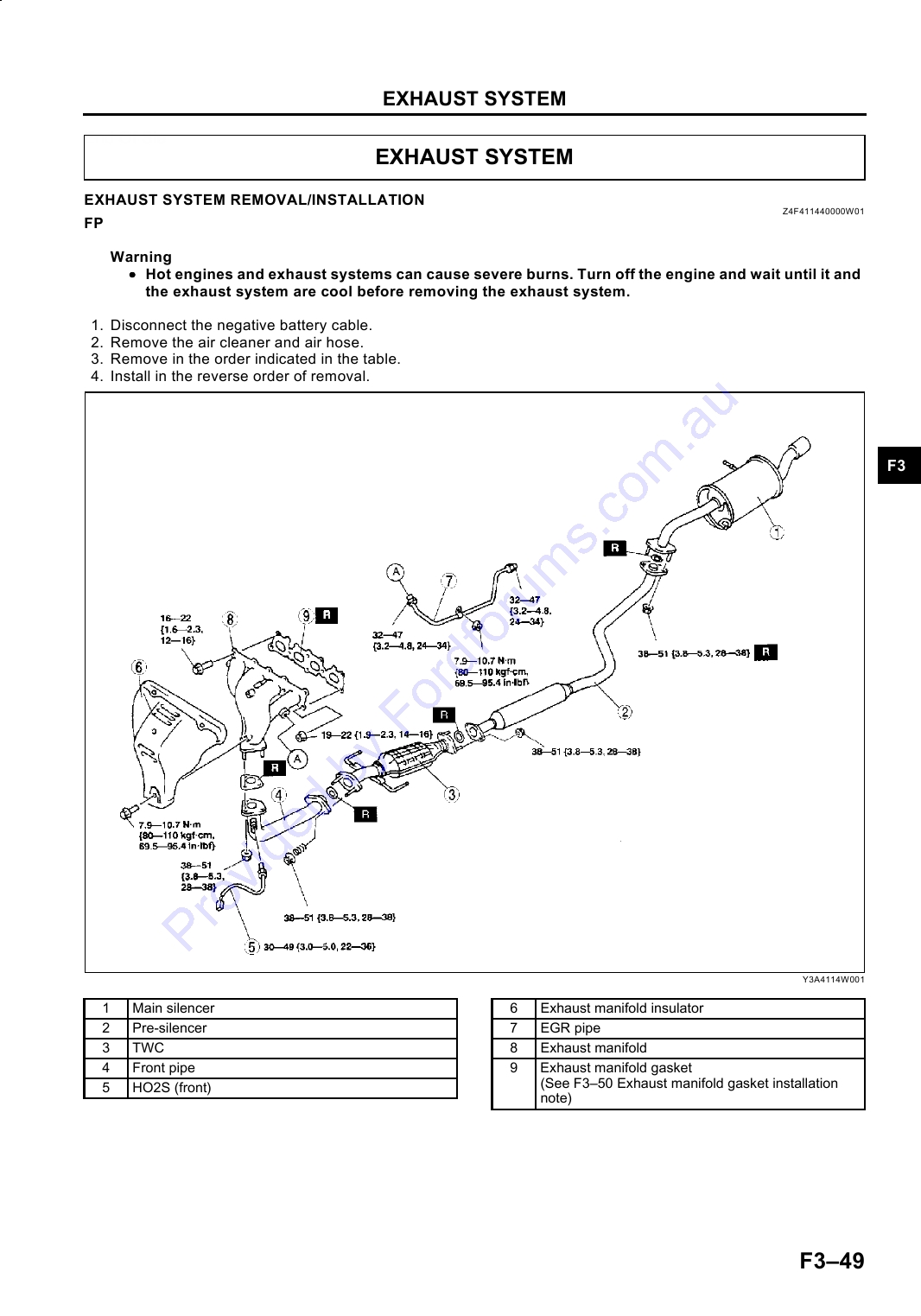

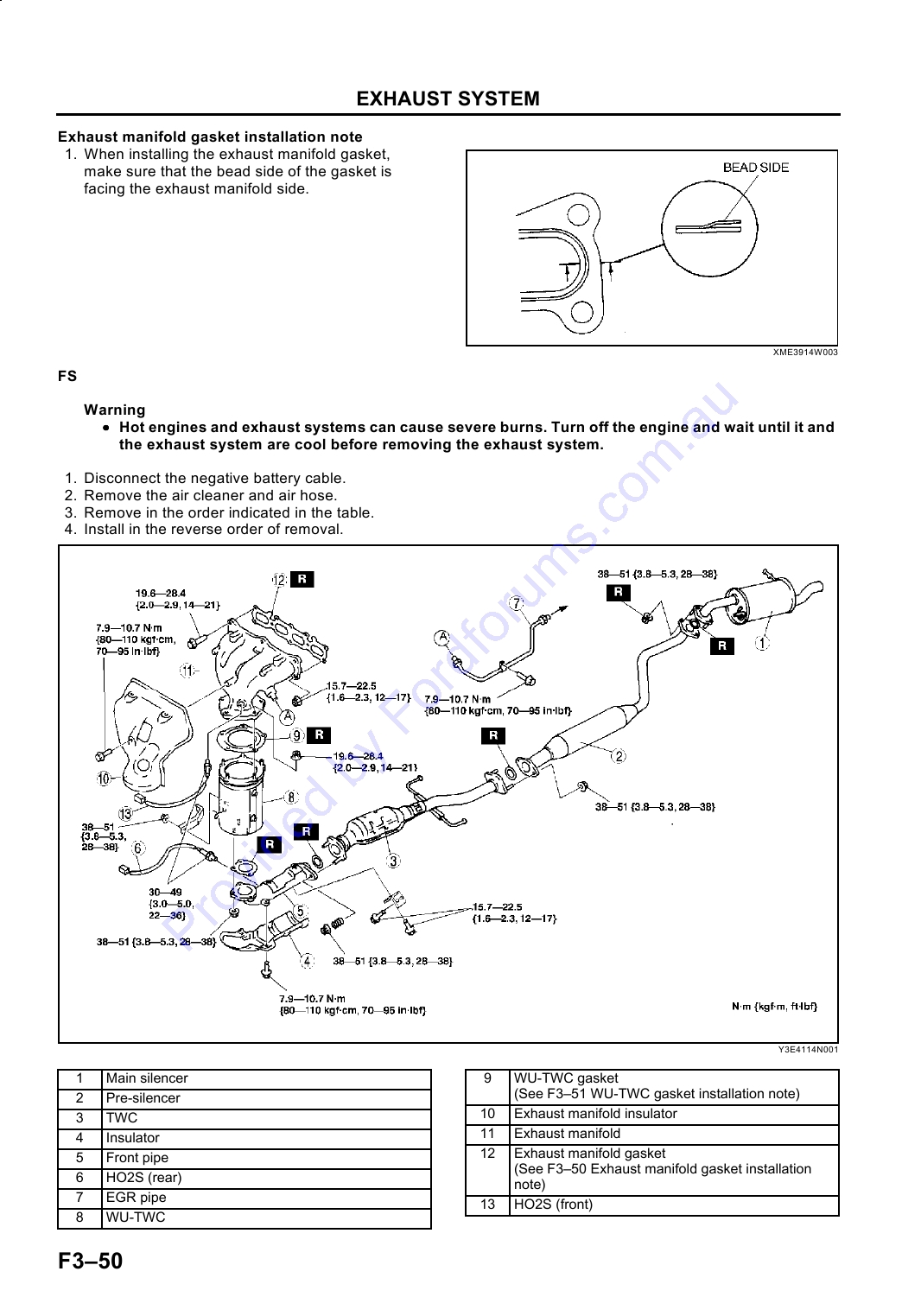

EXHAUST SYSTEM ........................................... F3-49

SPECIFICATIONS ............................................. F3-3

EXHAUST SYSTEM

CONTROL SYSTEM DIAGRAM (FS) ................ F3-4

REMOVAL/INSTALLATION .......................... F3-49

CONTROL SYSTEM WIRING DIAGRAM (FS).. F3-6

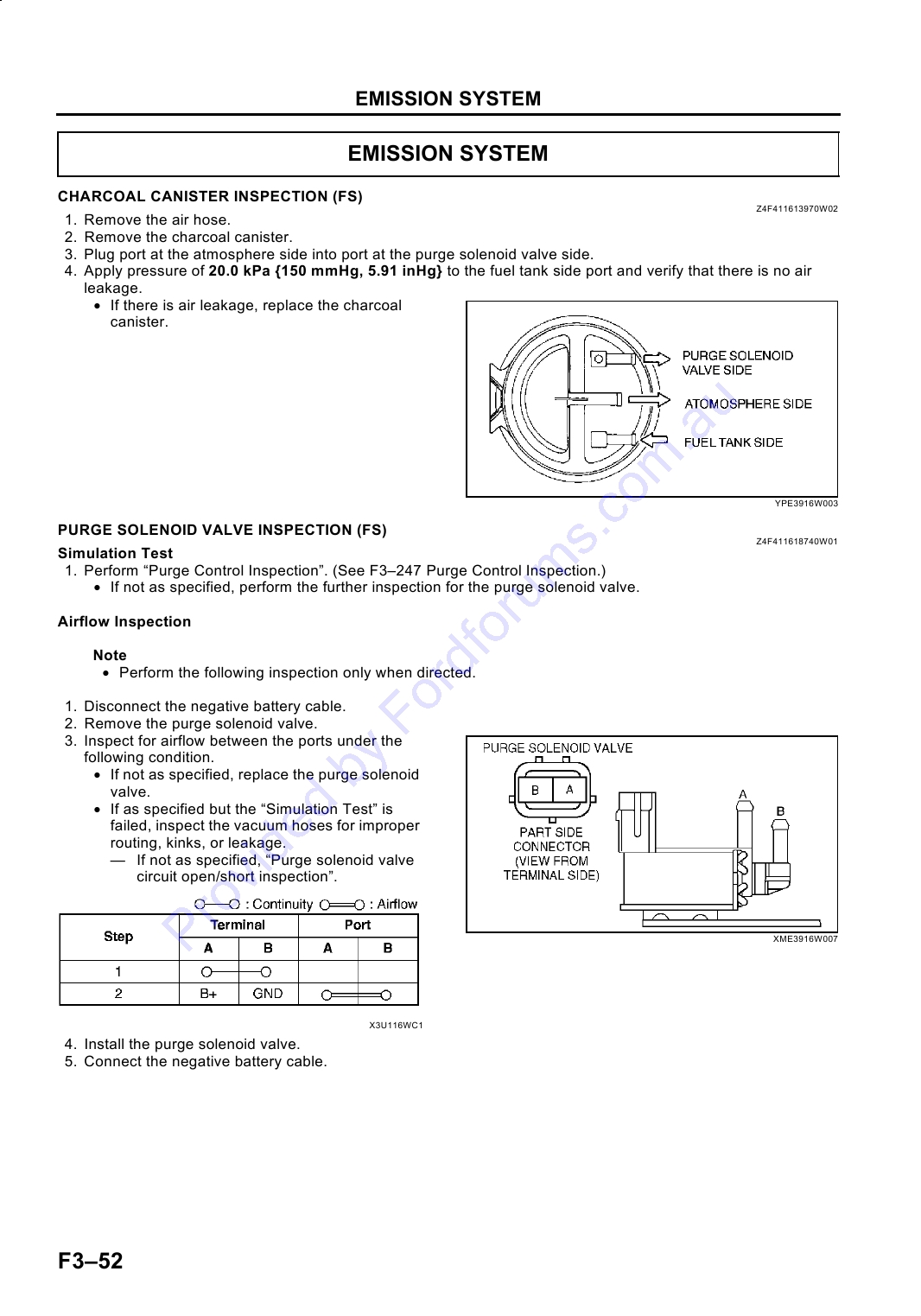

EMISSION SYSTEM ........................................... F3-52

FUEL SYSTEM ..................................................... F3-9

CHARCOAL CANISTER INSPECTION (FS) ... F3-52

OUTLINE ........................................................... F3-9

PURGE SOLENOID VALVE

STRUCTURAL VIEW......................................... F3-9

INSPECTION (FS) ........................................ F3-52

QUICK RELEASE CONNECTOR

F3

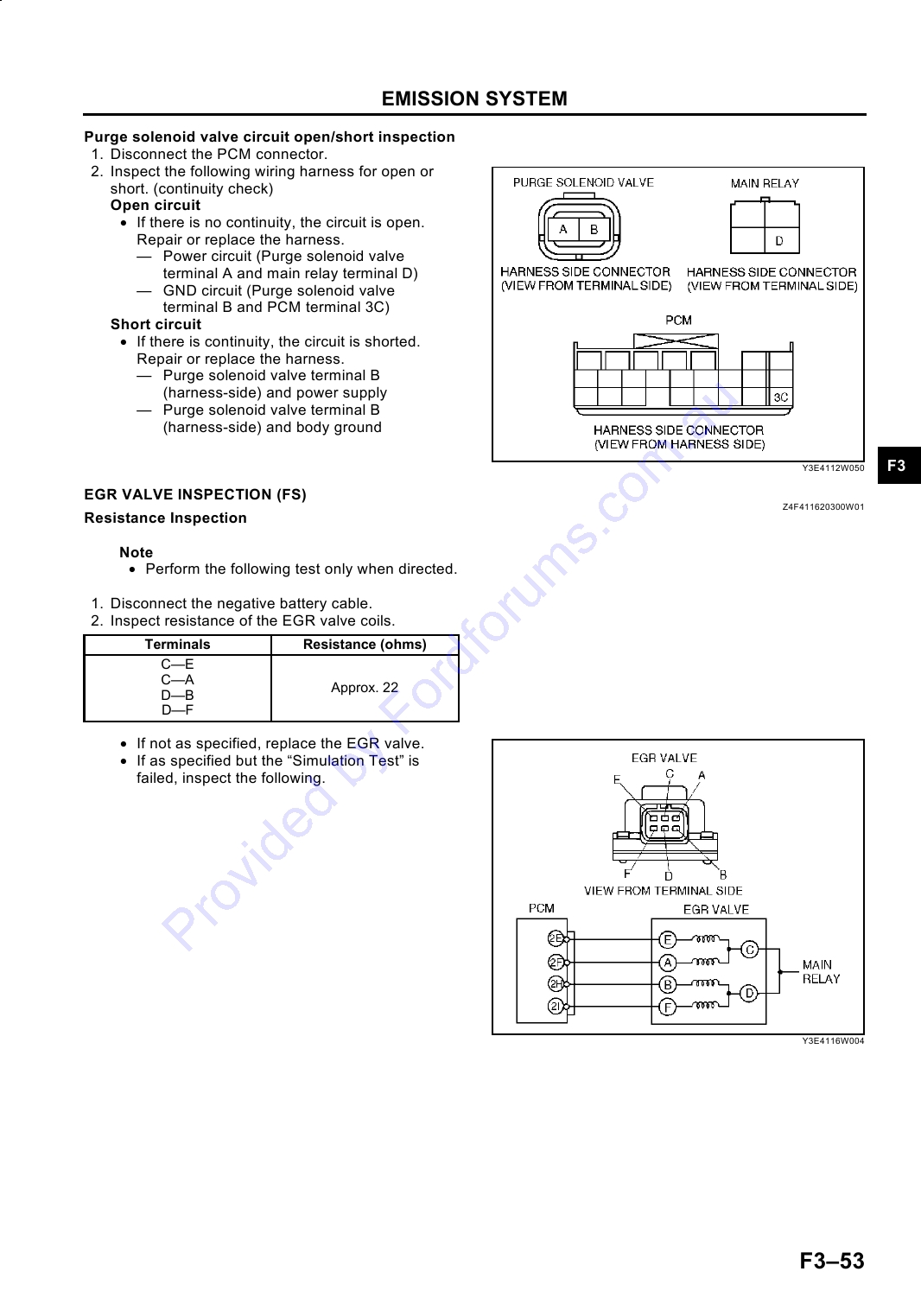

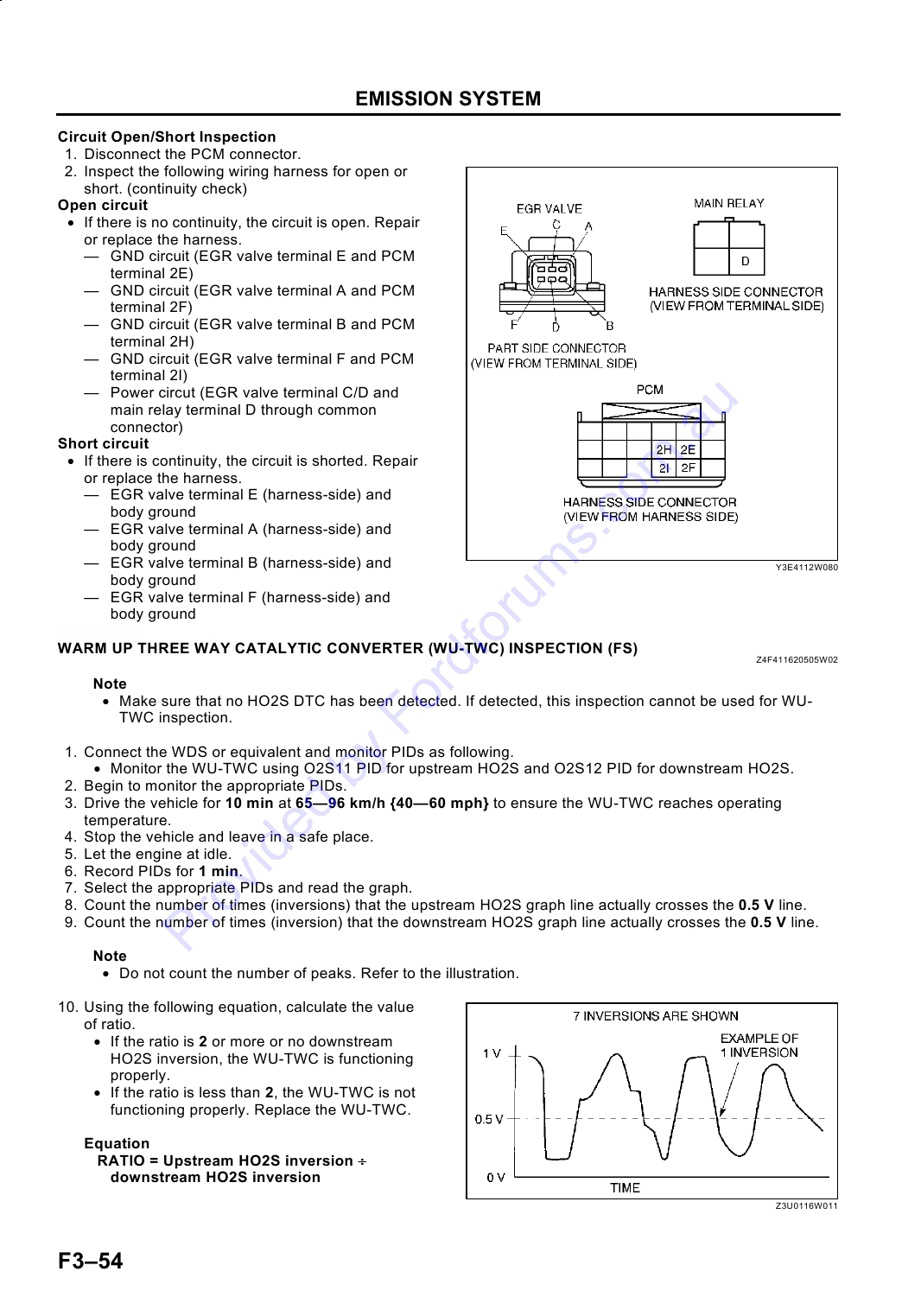

EGR VALVE INSPECTION (FS)...................... F3-53

(ENGINE ROOM SIDE) ................................ F3-10

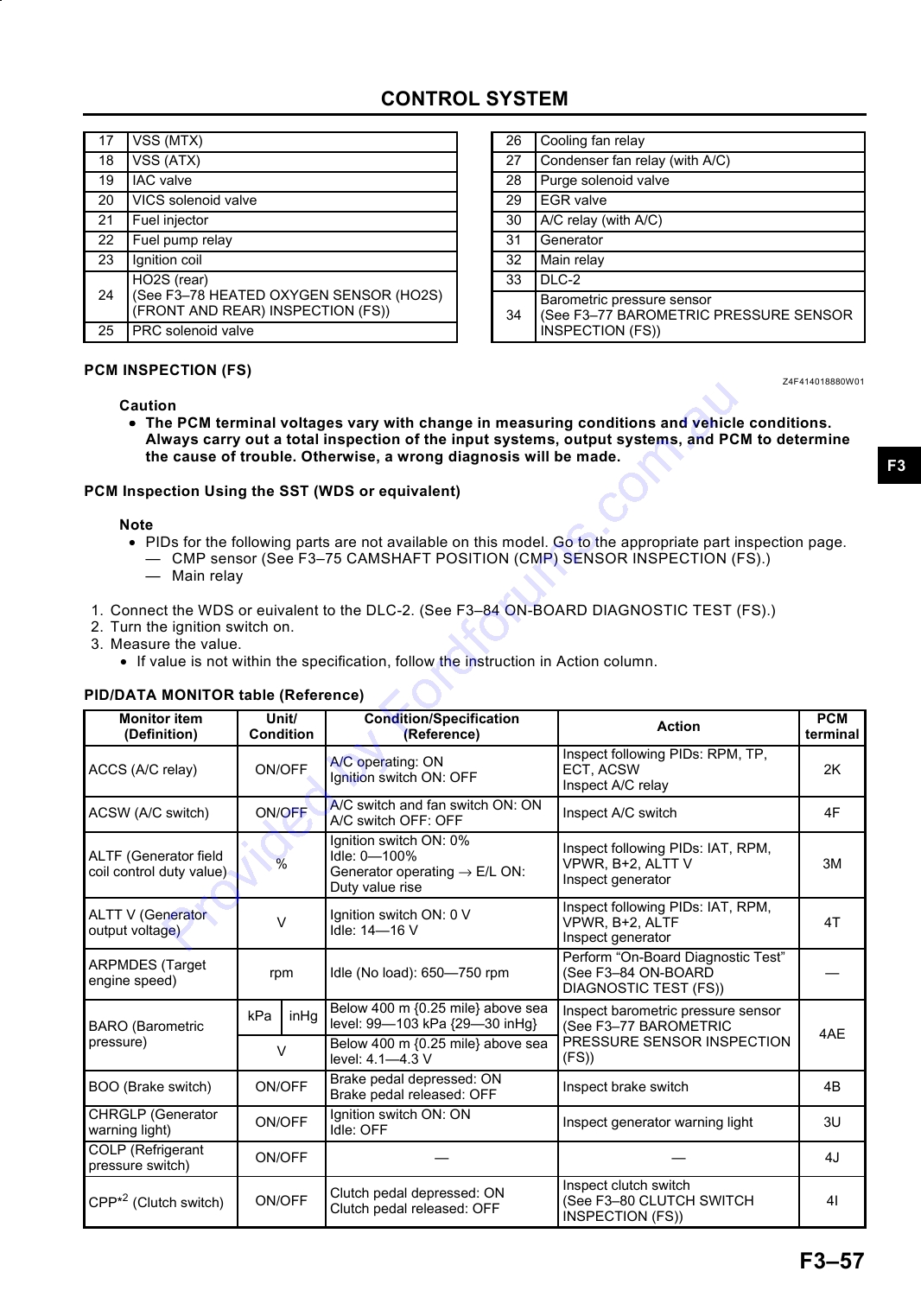

WARM UP THREE WAY CATALYTIC

QUICK RELEASE CONNECTOR

CONVERTER (WU-TWC) INSPECTION

(FUEL DISTRIBUTOR SIDE)........................ F3-11

(FS) ............................................................... F3-54

EMISSION SYSTEM ........................................... F3-12

CONTROL SYSTEM........................................... F3-56

OUTLINE ......................................................... F3-12

CONTROL SYSTEM COMPONENT

STRUCTURAL VIEW (FS)............................... F3-12

LOCATION INDEX (FS)................................ F3-56

CHARCOAL CANISTER (FS) .......................... F3-13

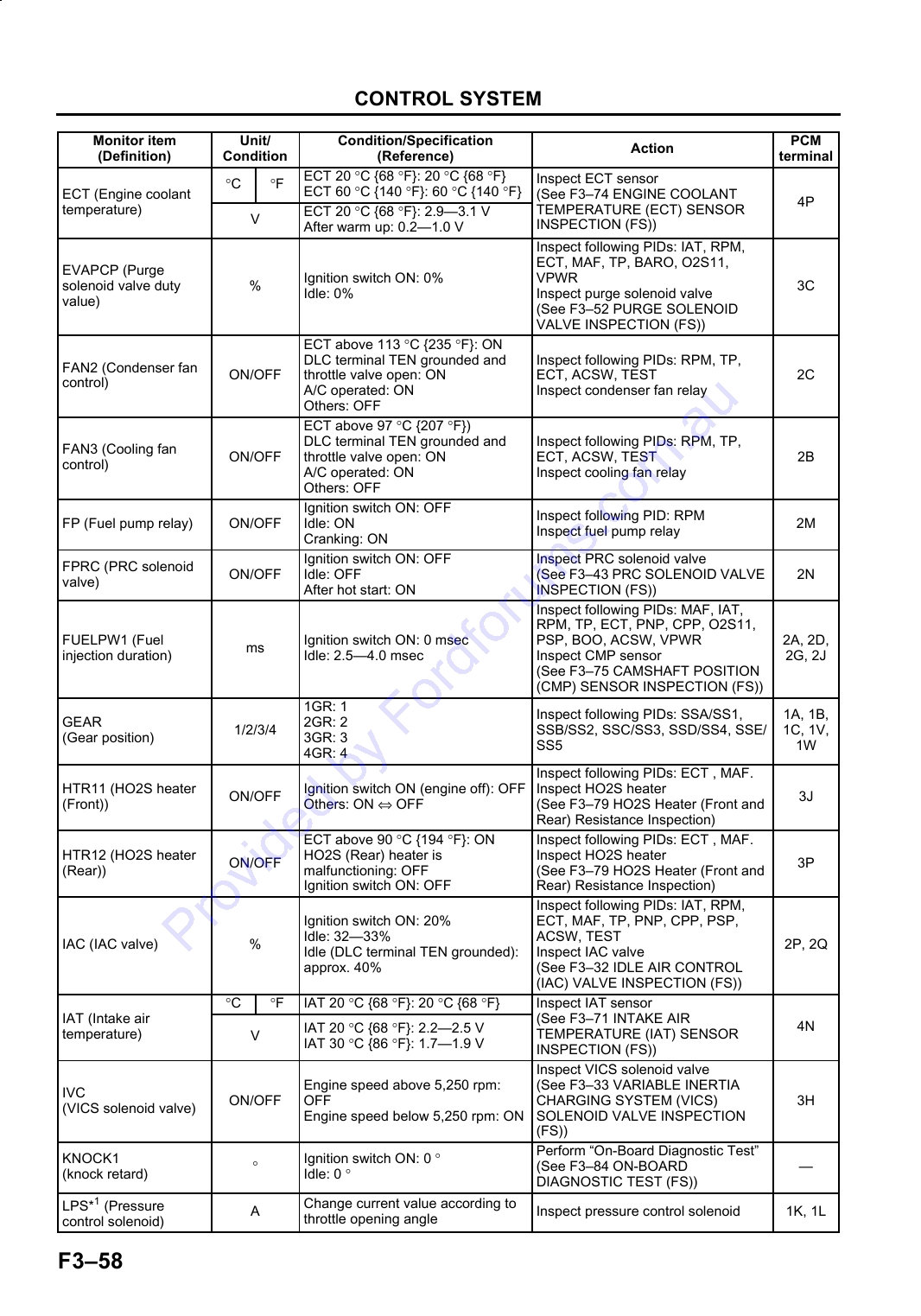

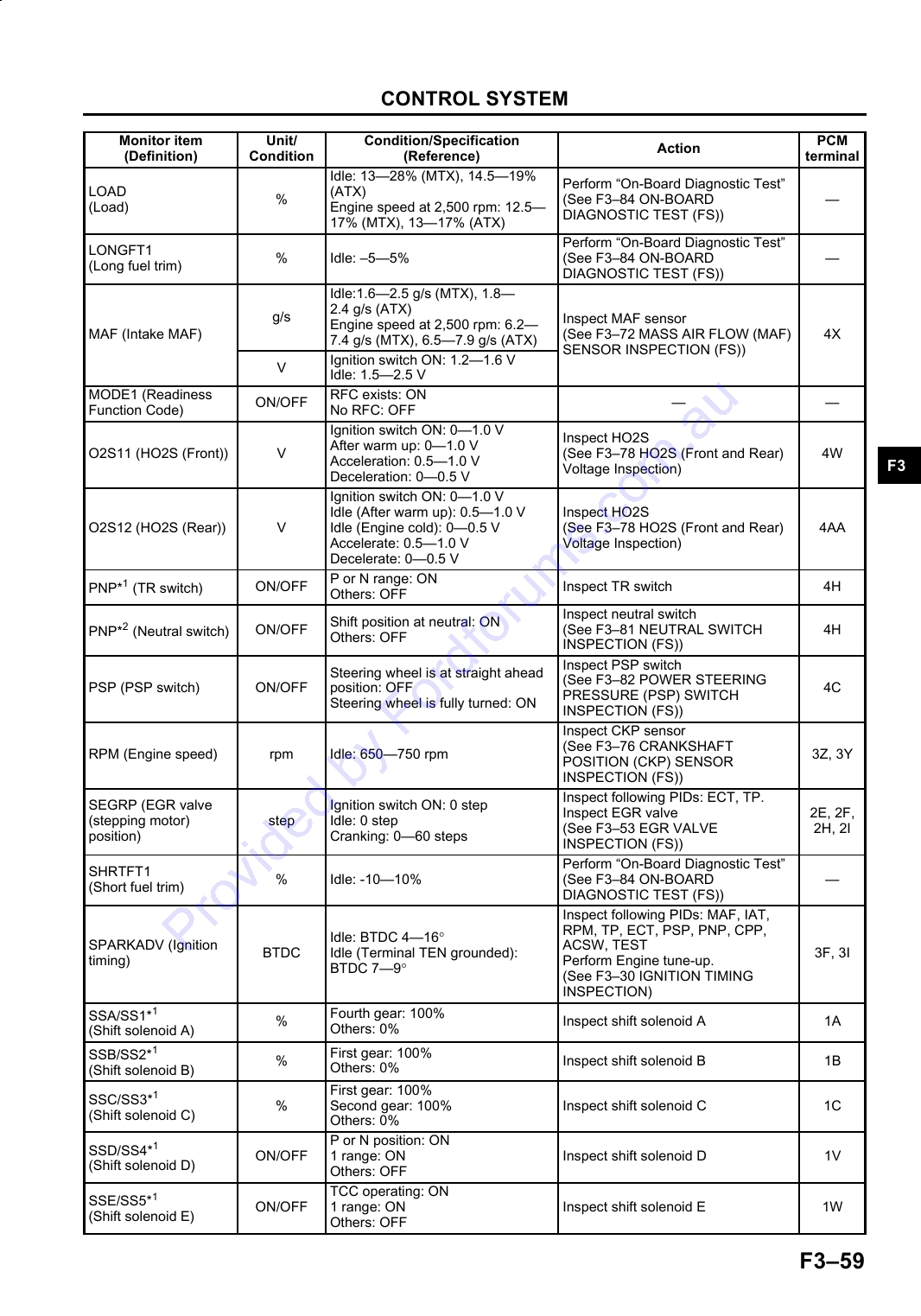

PCM INSPECTION (FS) .................................. F3-57

WARM UP THREE WAY CATALYTIC

INTAKE AIR TEMPERATURE (IAT) SENSOR

CONVERTER (WU-TWC) (FS)..................... F3-13

INSPECTION (FS) ........................................ F3-71

CONTROL SYSTEM........................................... F3-14

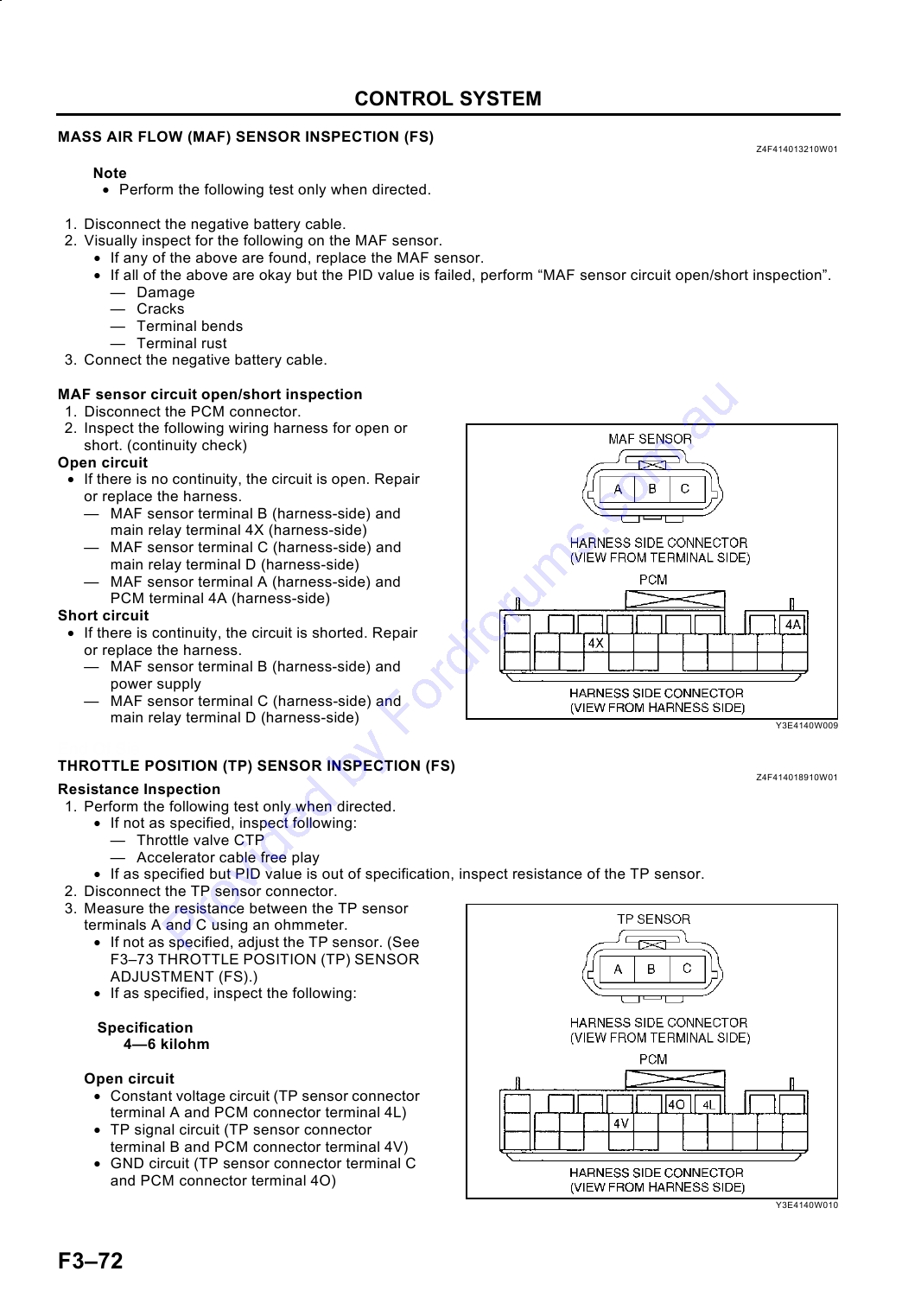

MASS AIR FLOW (MAF) SENSOR

OUTLINE ......................................................... F3-14

INSPECTION (FS) ........................................ F3-72

BLOCK DIAGRAM (FS) ................................... F3-14

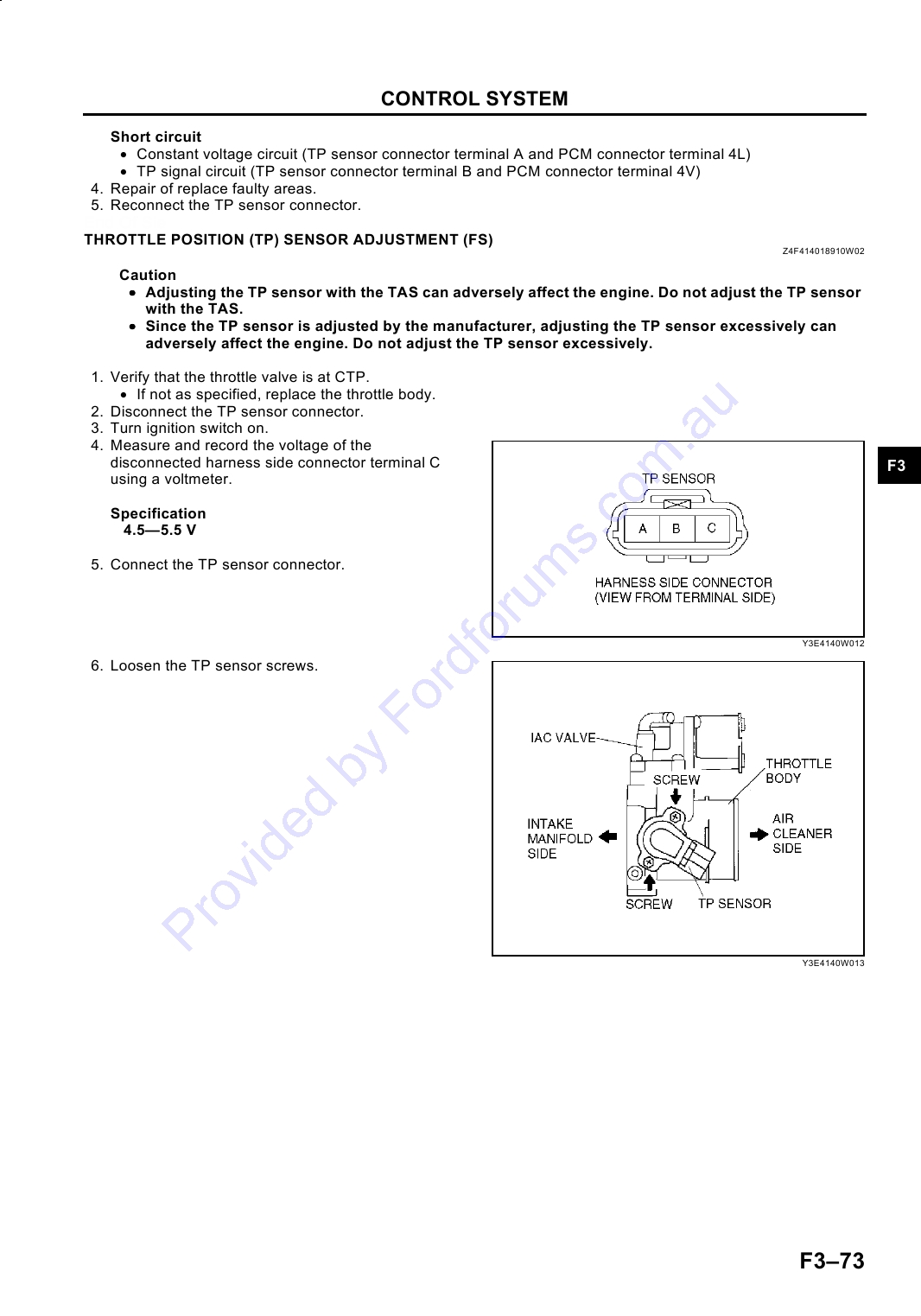

THROTTLE POSITION (TP) SENSOR

CONTROL DEVICES AND CONTROL

INSPECTION (FS) ........................................ F3-72

RELATIONSHIP CHART (FS) ...................... F3-16

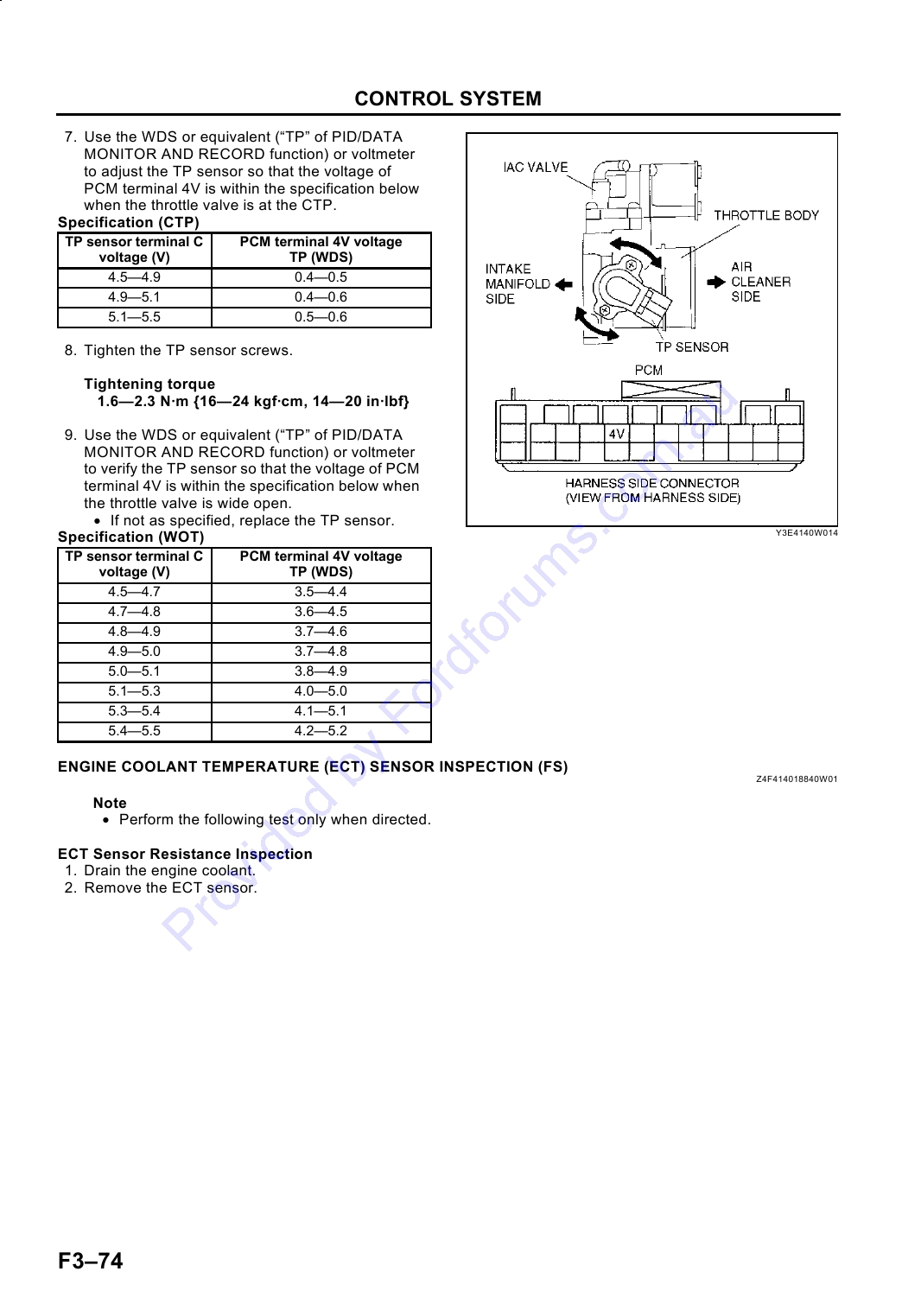

THROTTLE POSITION (TP) SENSOR

BAROMETRIC PRESSURE SENSOR (FS) .... F3-18

ADJUSTMENT (FS) ...................................... F3-73

REAR HEATED OXYGEN SENSOR

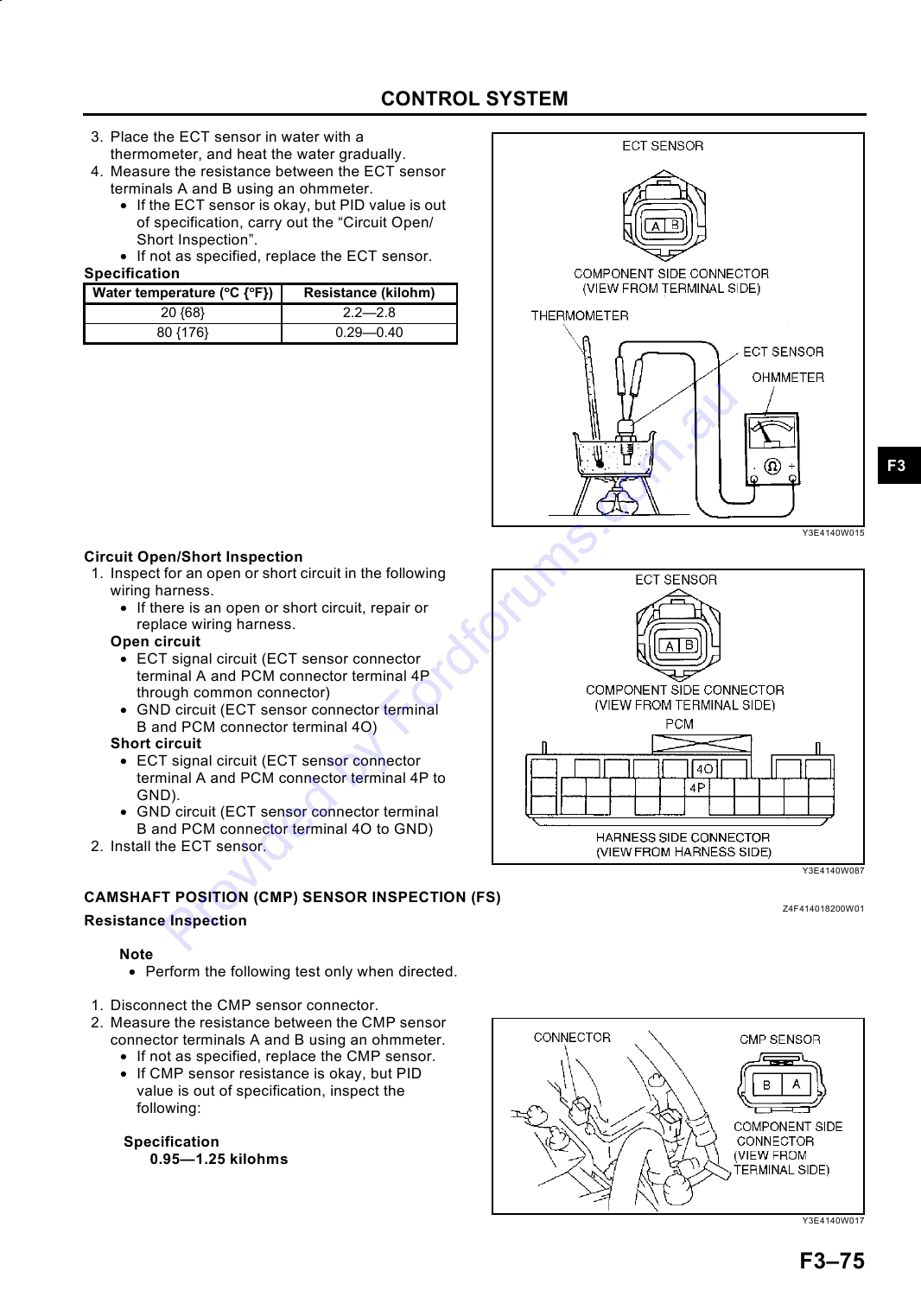

ENGINE COOLANT TEMPERATURE (ECT)

(HO2S) (FS).................................................. F3-19

SENSOR INSPECTION (FS) ........................ F3-74

ON-BOARD DIAGNOSTIC ................................. F3-21

CAMSHAFT POSITION (CMP) SENSOR

OUTLINE ......................................................... F3-21

INSPECTION (FS) ........................................ F3-75

DIAGNOSTIC TEST MODE (FS)..................... F3-21

CRANKSHAFT POSITION (CKP) SENSOR

DTC (FS).......................................................... F3-24

INSPECTION (FS) ........................................ F3-76

PID/DATA MONITOR AND RECORD ............. F3-27

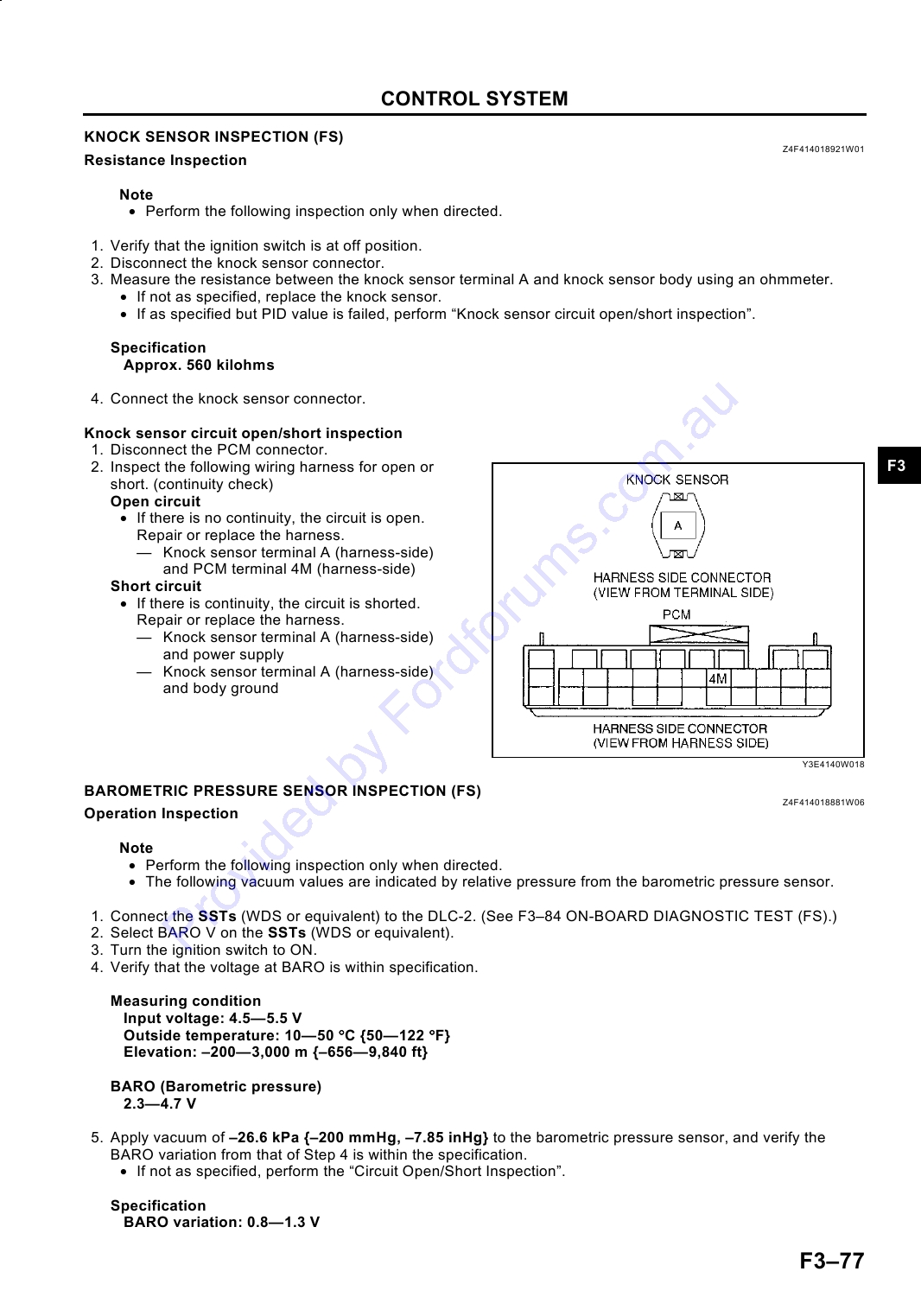

KNOCK SENSOR INSPECTION (FS) ............. F3-77

SIMULATION TEST......................................... F3-28

BAROMETRIC PRESSURE SENSOR

INSPECTION (FS) ........................................ F3-77

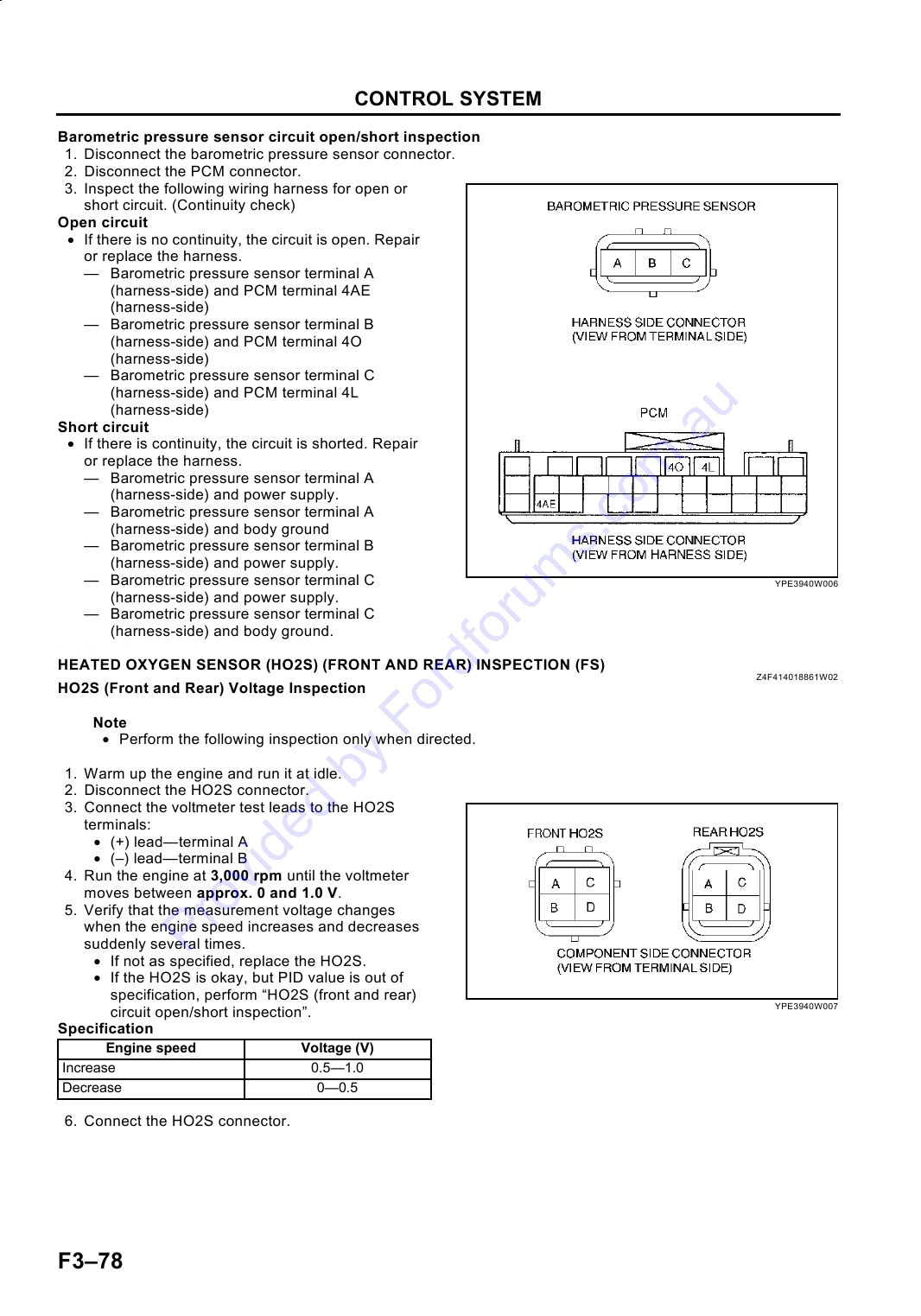

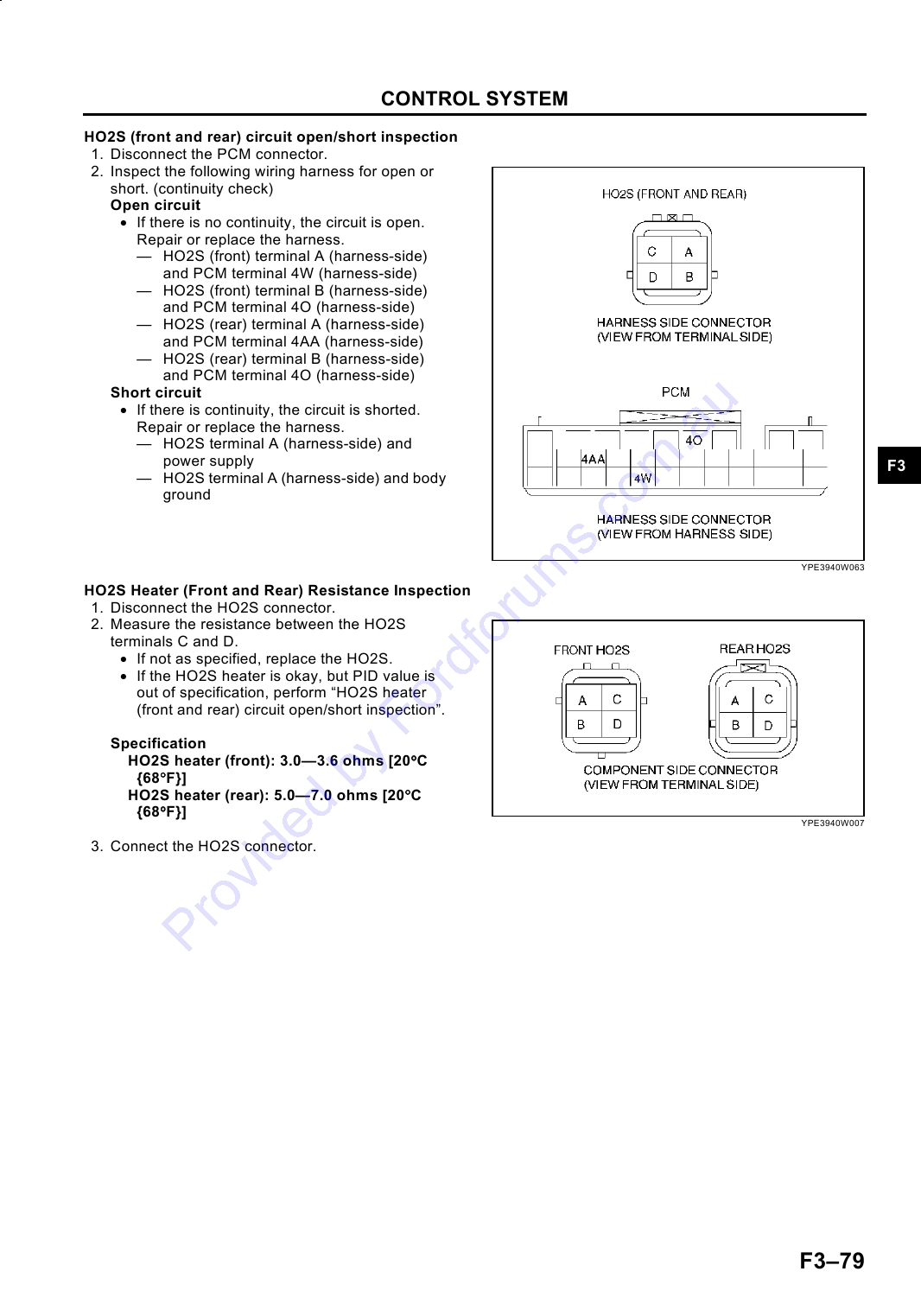

HEATED OXYGEN SENSOR (HO2S)

SERVICE

(FRONT AND REAR) INSPECTION (FS)..... F3-78

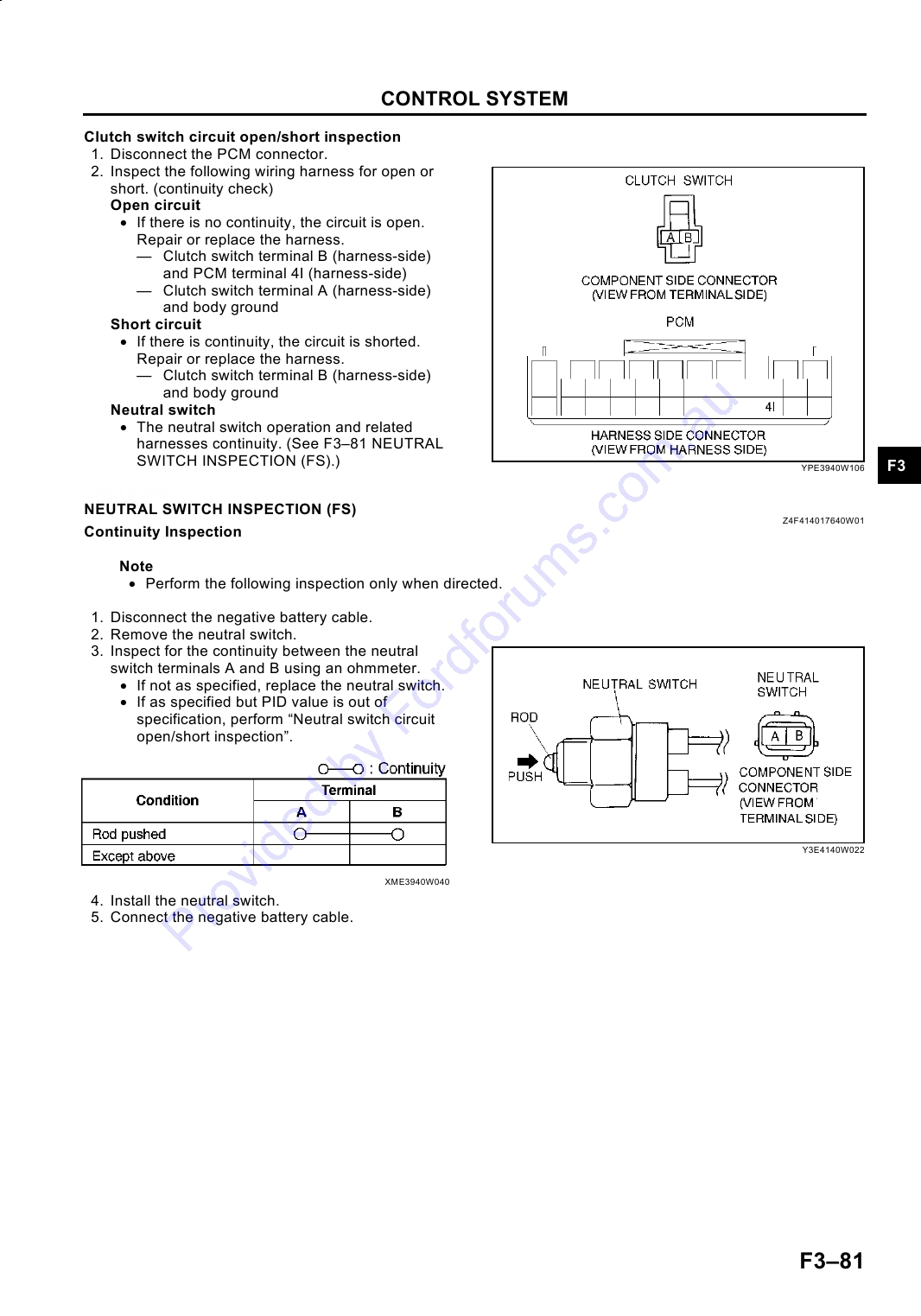

CLUTCH SWITCH INSPECTION (FS) ............ F3-80

OUTLINE ............................................................ F3-29

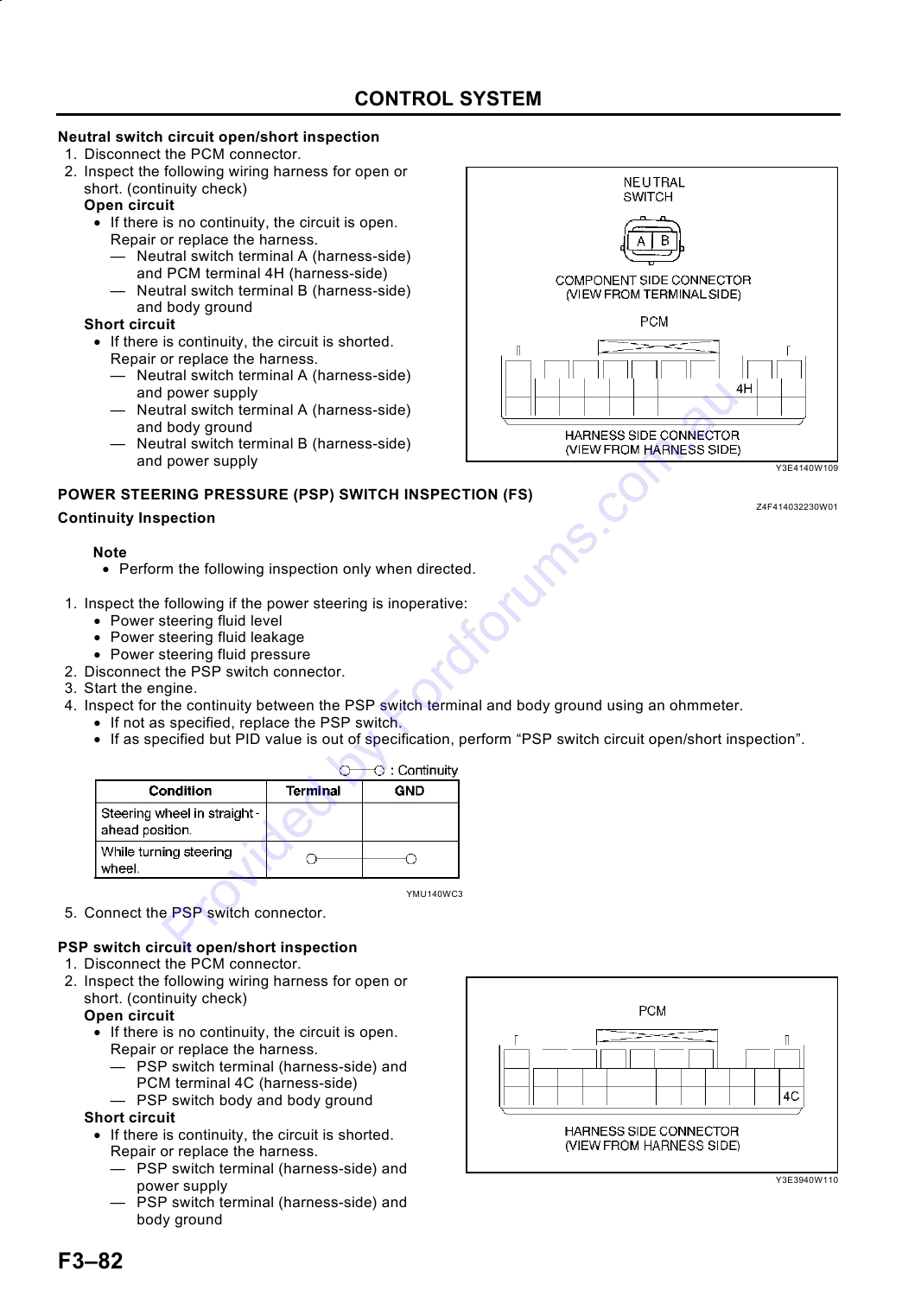

NEUTRAL SWITCH INSPECTION (FS) .......... F3-81

SUPPLEMENTAL SERVICE INFORMATION . F3-29

POWER STEERING PRESSURE (PSP)

ENGINE TUNE-UP ............................................. F3-30

SWITCH INSPECTION (FS) ......................... F3-82

ENGINE TUNE-UP PREPARATION ............... F3-30

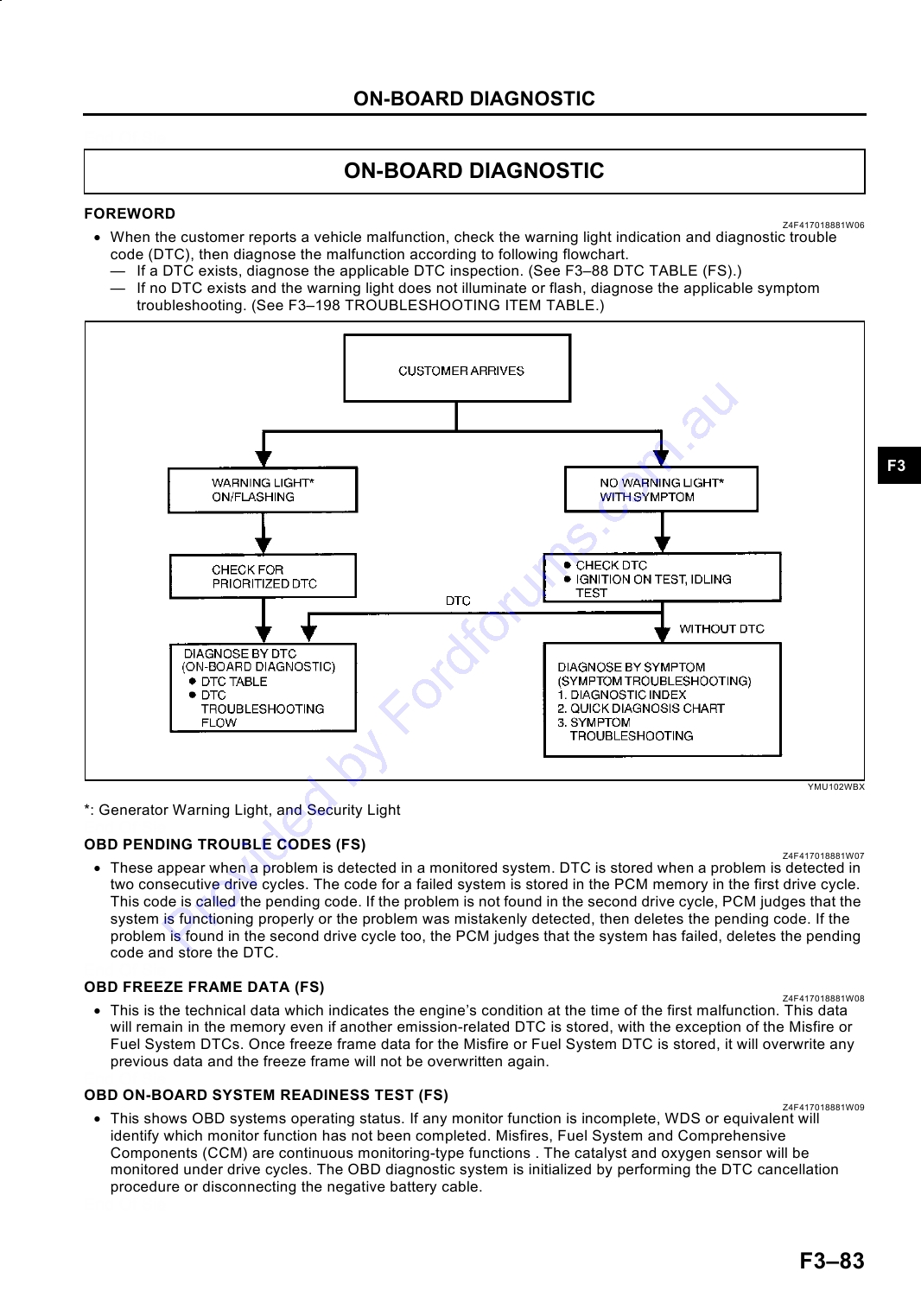

ON-BOARD DIAGNOSTIC ................................. F3-83

IGNITION TIMING INSPECTION .................... F3-30

FOREWORD .................................................... F3-83

IDLE SPEED ADJUSTMENT........................... F3-31

OBD PENDING TROUBLE CODES (FS) ........ F3-83

IDLE-UP SPEED INSPECTION....................... F3-31

OBD FREEZE FRAME DATA (FS) .................. F3-83

INTAKE-AIR SYSTEM........................................ F3-32

OBD ON-BOARD SYSTEM READINESS

VACUUM HOSE ROUTING DIAGRAM (FS) ... F3-32

TEST (FS) ..................................................... F3-83

IDLE AIR CONTROL (IAC) VALVE

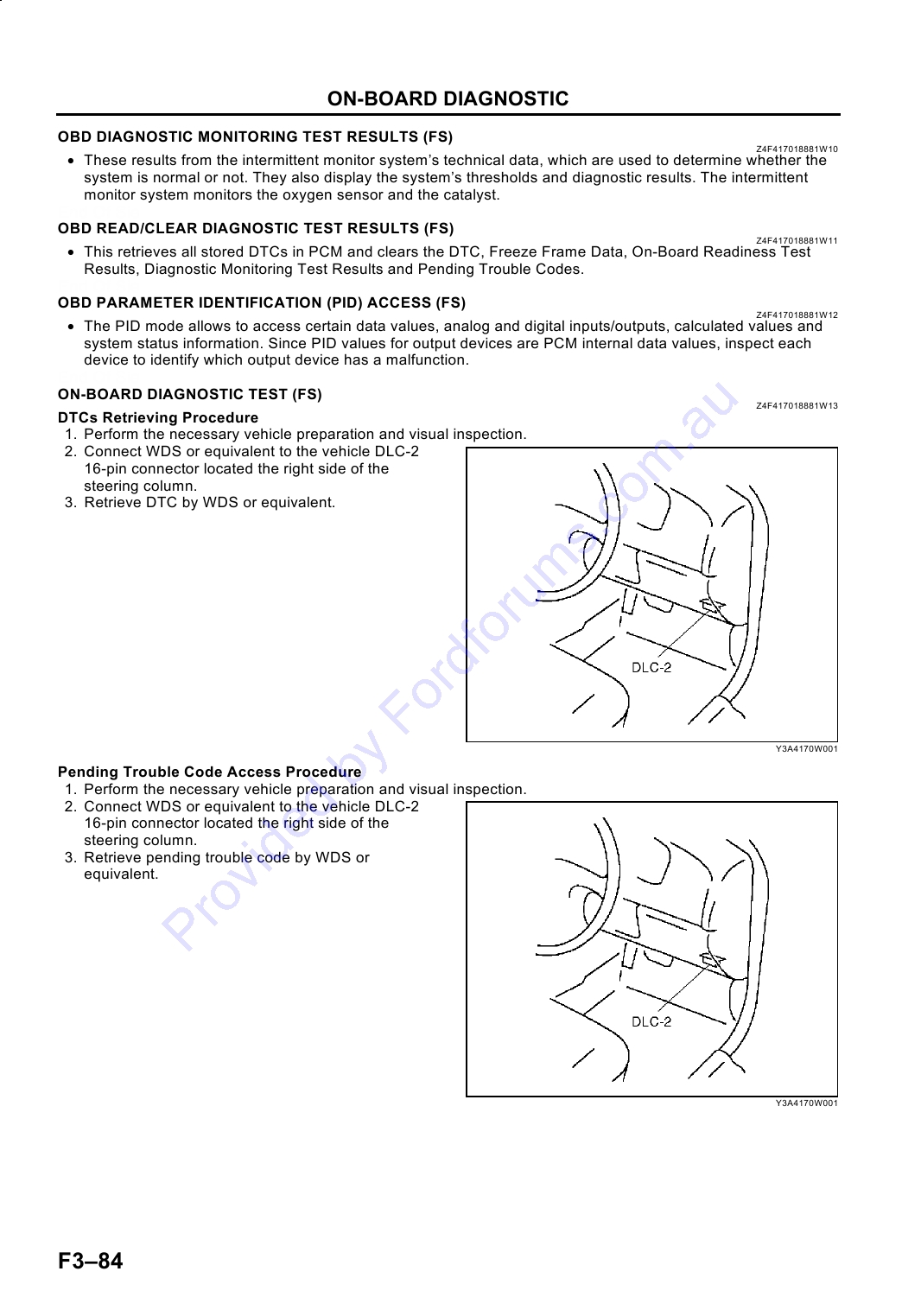

OBD DIAGNOSTIC MONITORING TEST

INSPECTION (FS) ........................................ F3-32

RESULTS (FS).............................................. F3-84

VARIABLE INERTIA CHARGING SYSTEM

OBD READ/CLEAR DIAGNOSTIC TEST

(VICS) SOLENOID VALVE INSPECTION

RESULTS (FS).............................................. F3-84

(FS) ............................................................... F3-33

OBD PARAMETER IDENTIFICATION (PID)

FUEL SYSTEM ................................................... F3-35

ACCESS (FS) ............................................... F3-84

FUEL PRESSURE INSPECTION .................... F3-35

ON-BOARD DIAGNOSTIC TEST (FS) ............ F3-84

FUEL INJECTOR REMOVAL/INSTALLATION F3-37

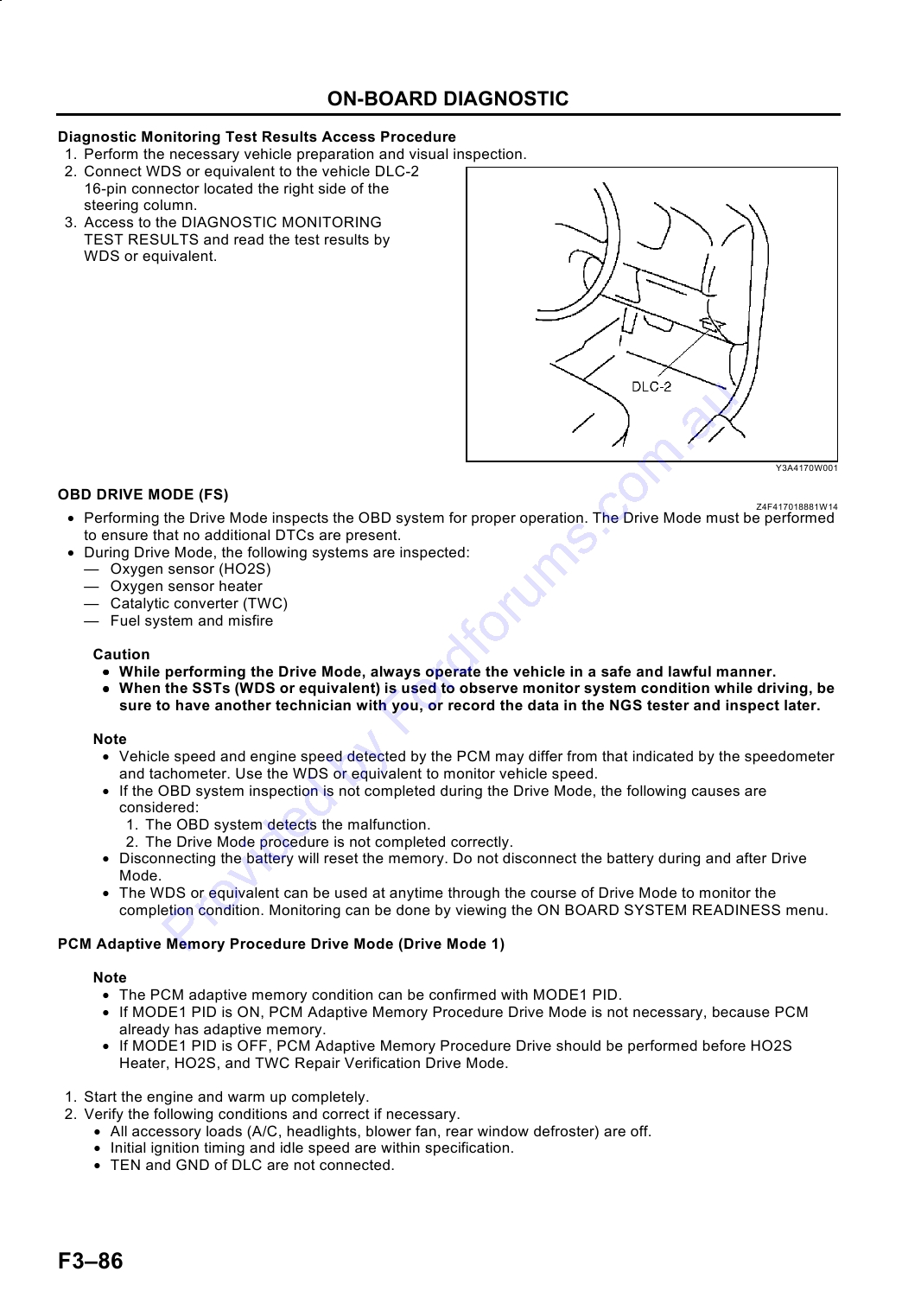

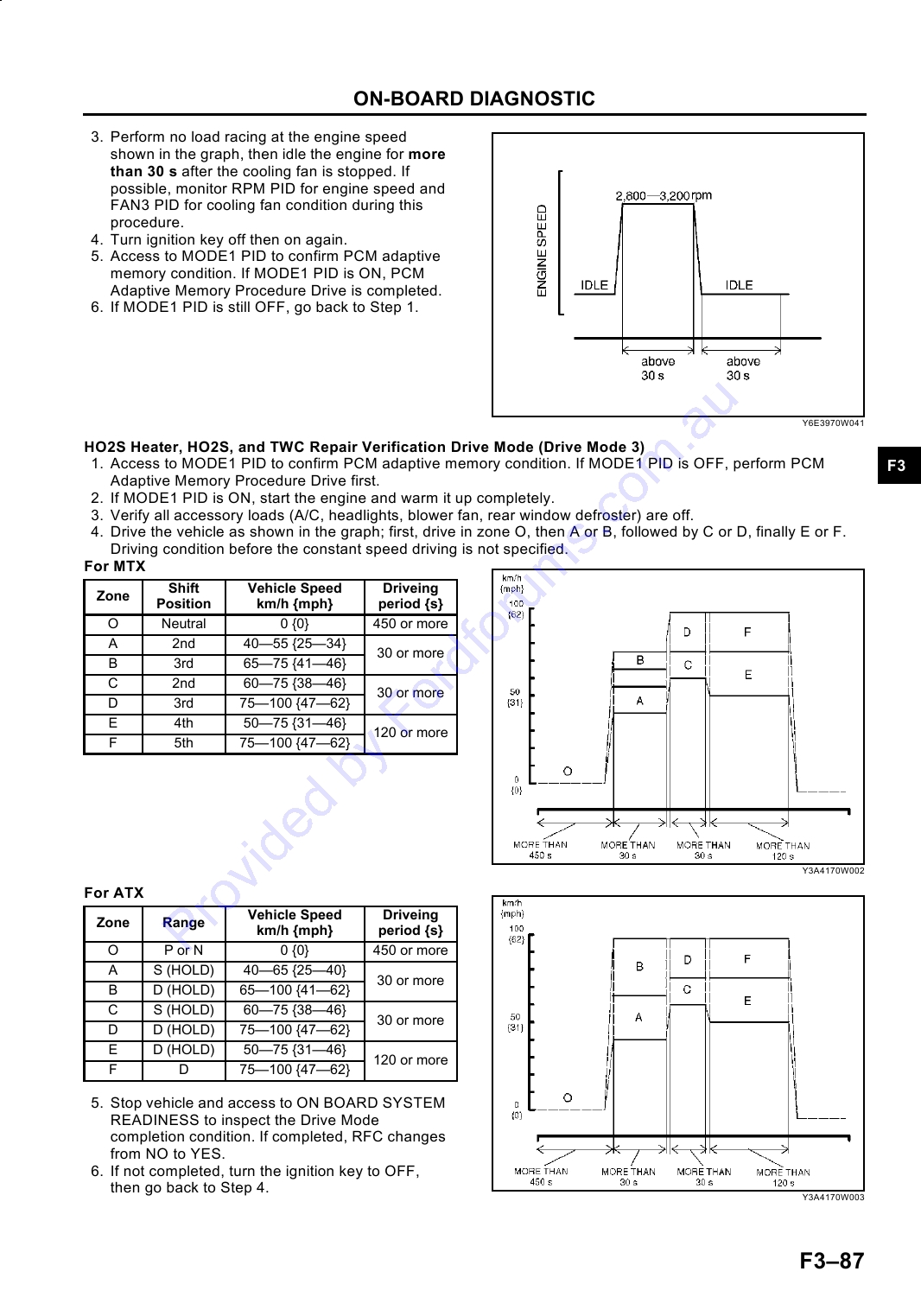

OBD DRIVE MODE (FS).................................. F3-86

FUEL INJECTOR INSPECTION (FS) .............. F3-40

F31

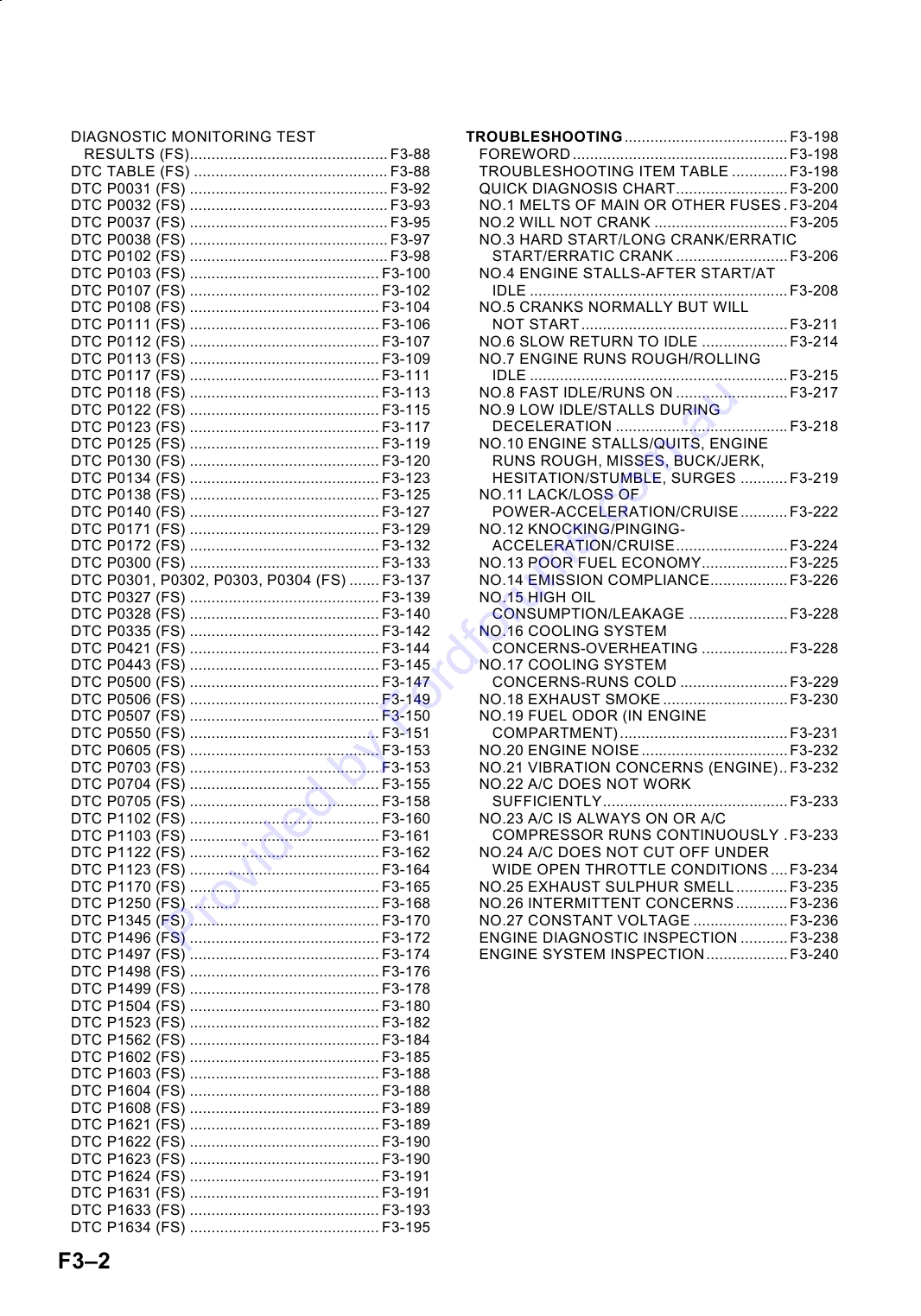

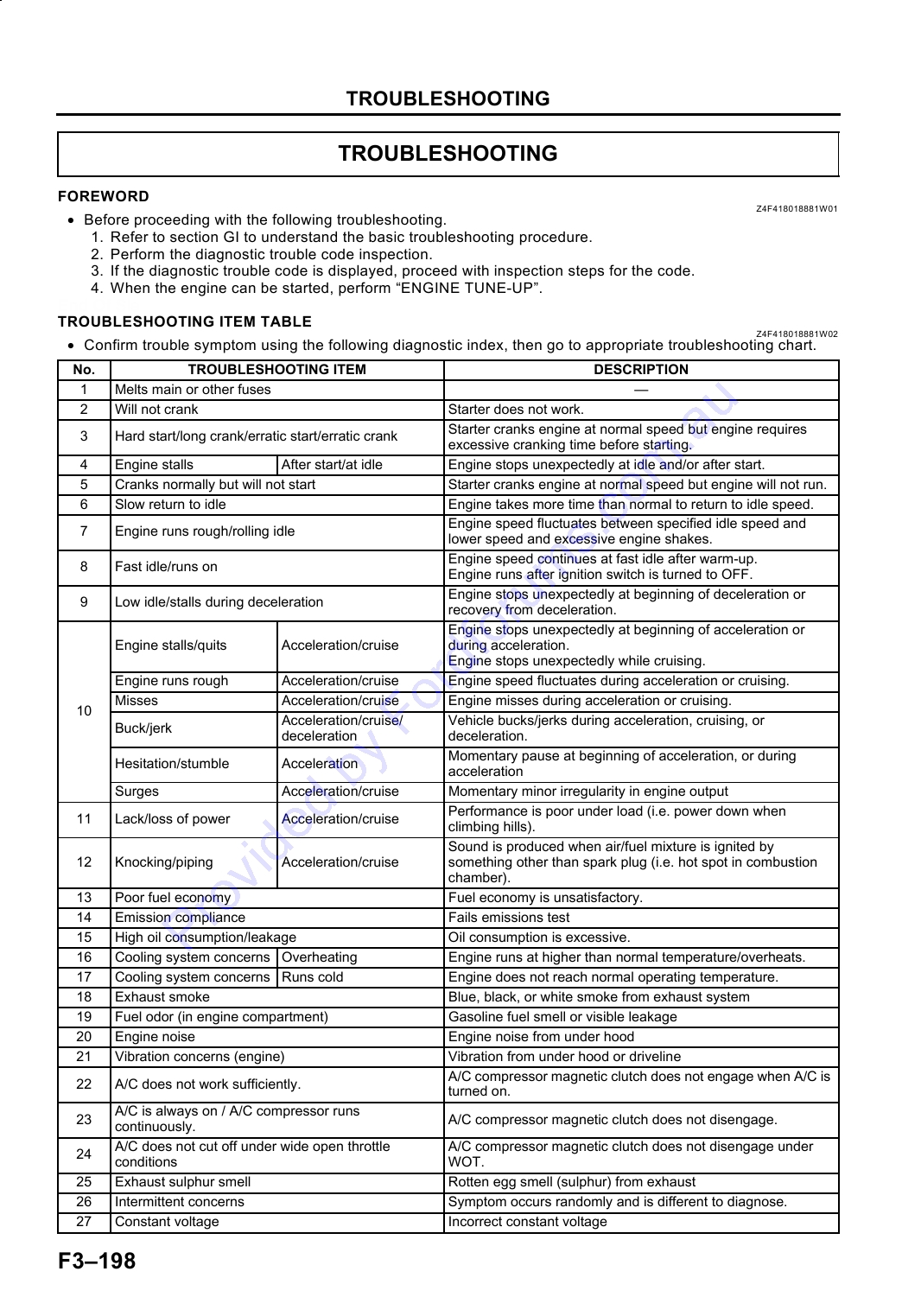

TROUBLESHOOTING ...................................... F3-198

DIAGNOSTIC MONITORING TEST

FOREWORD .................................................. F3-198

RESULTS (FS).............................................. F3-88

TROUBLESHOOTING ITEM TABLE ............. F3-198

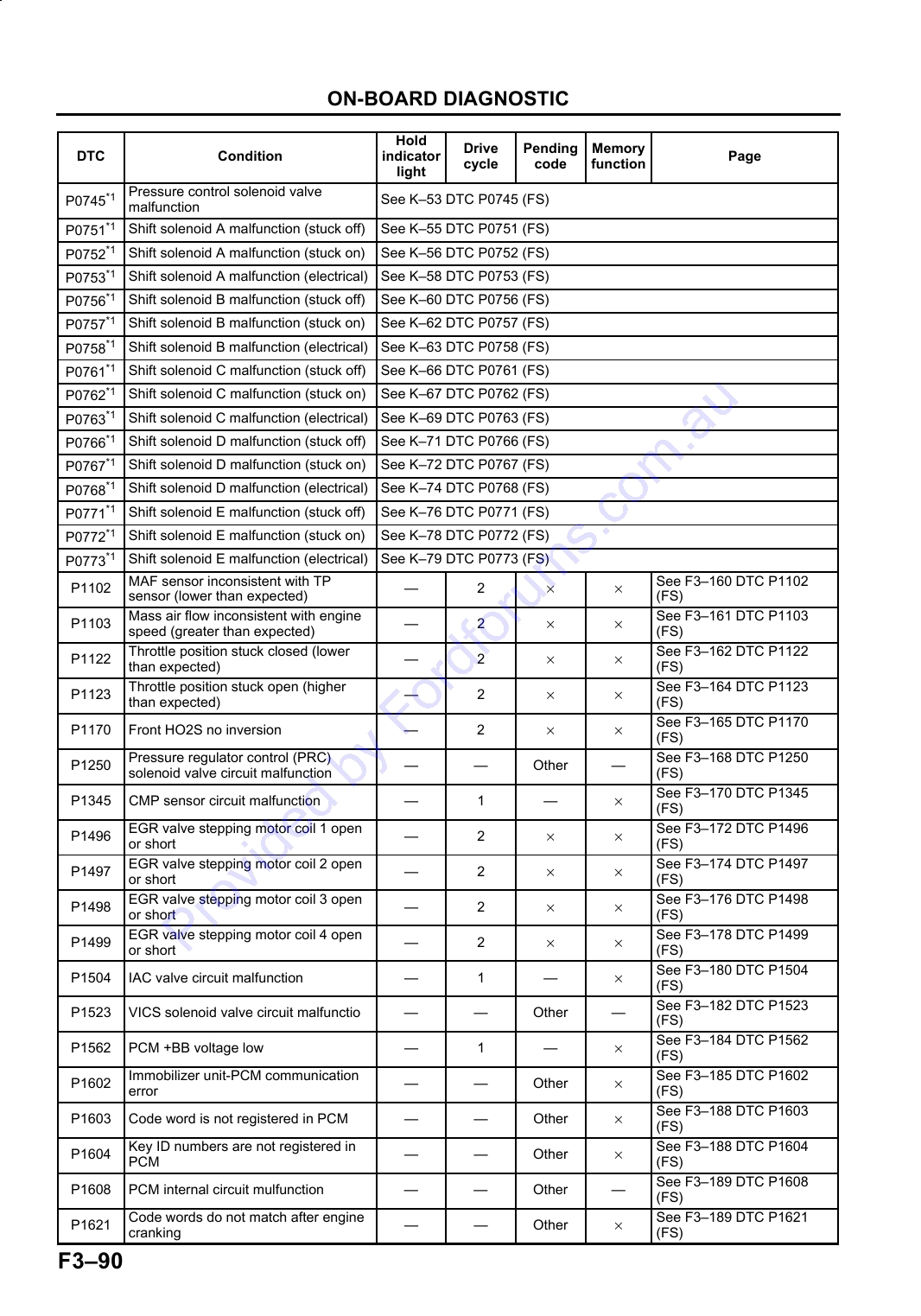

DTC TABLE (FS) ............................................. F3-88

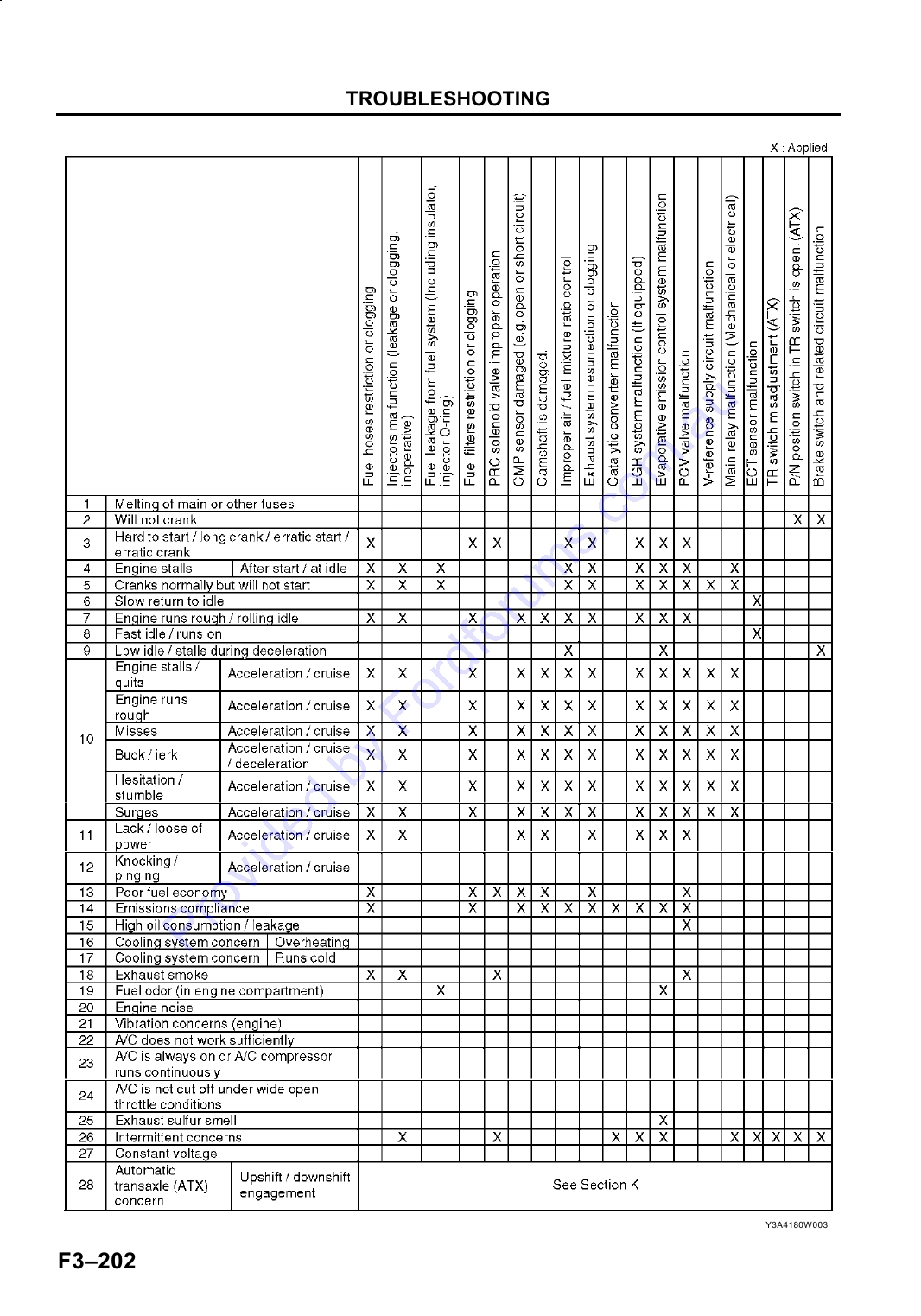

QUICK DIAGNOSIS CHART.......................... F3-200

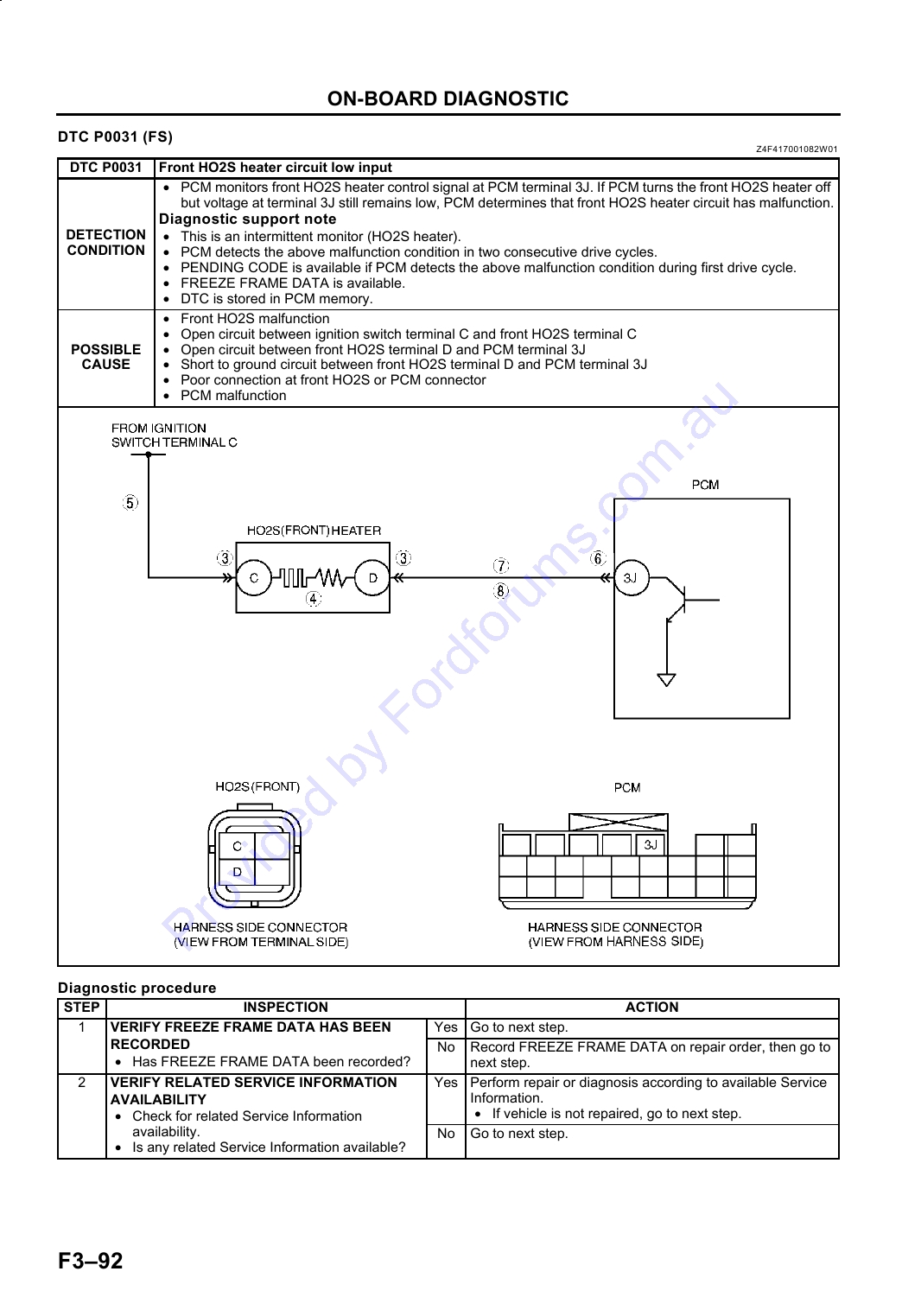

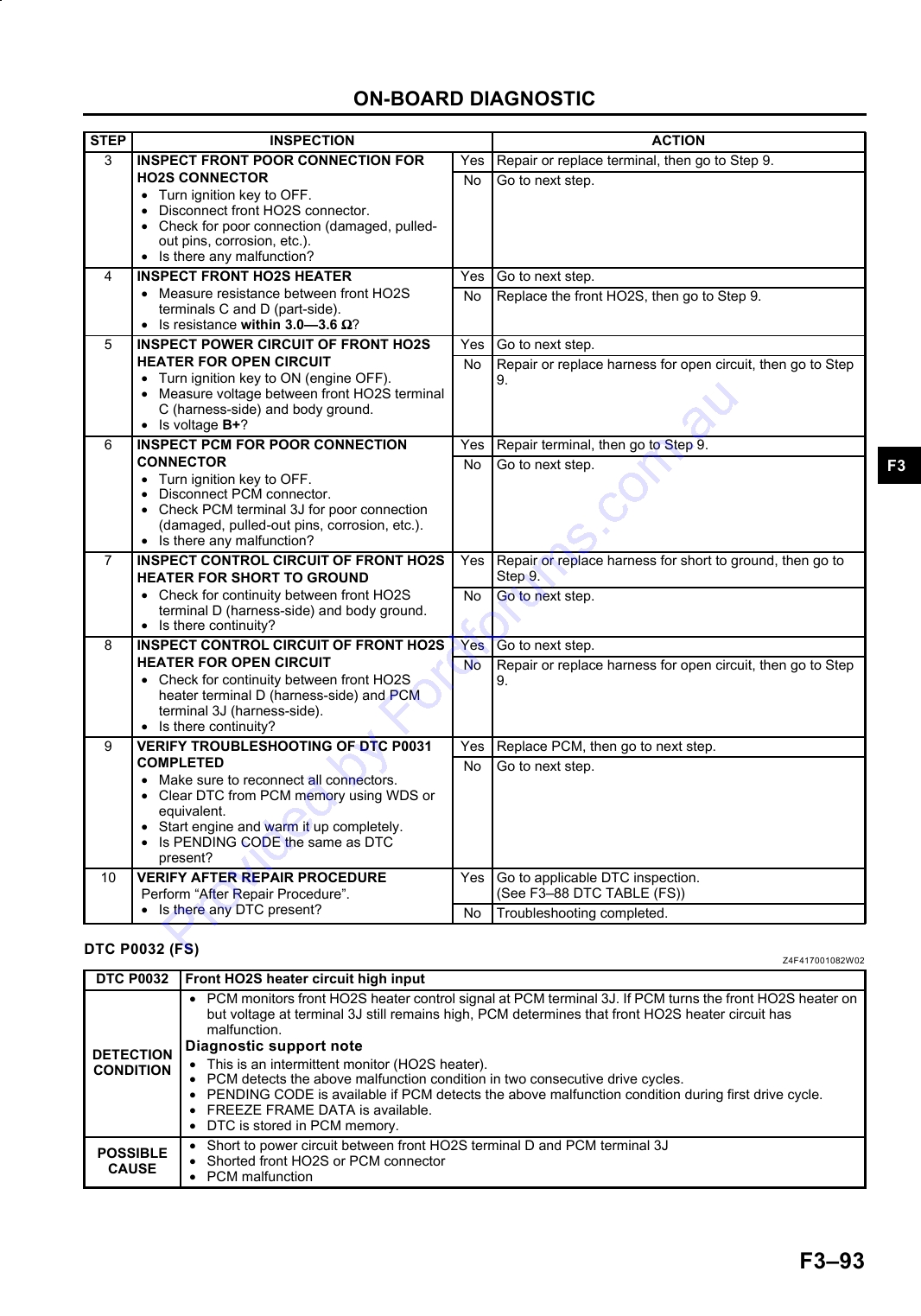

DTC P0031 (FS) .............................................. F3-92

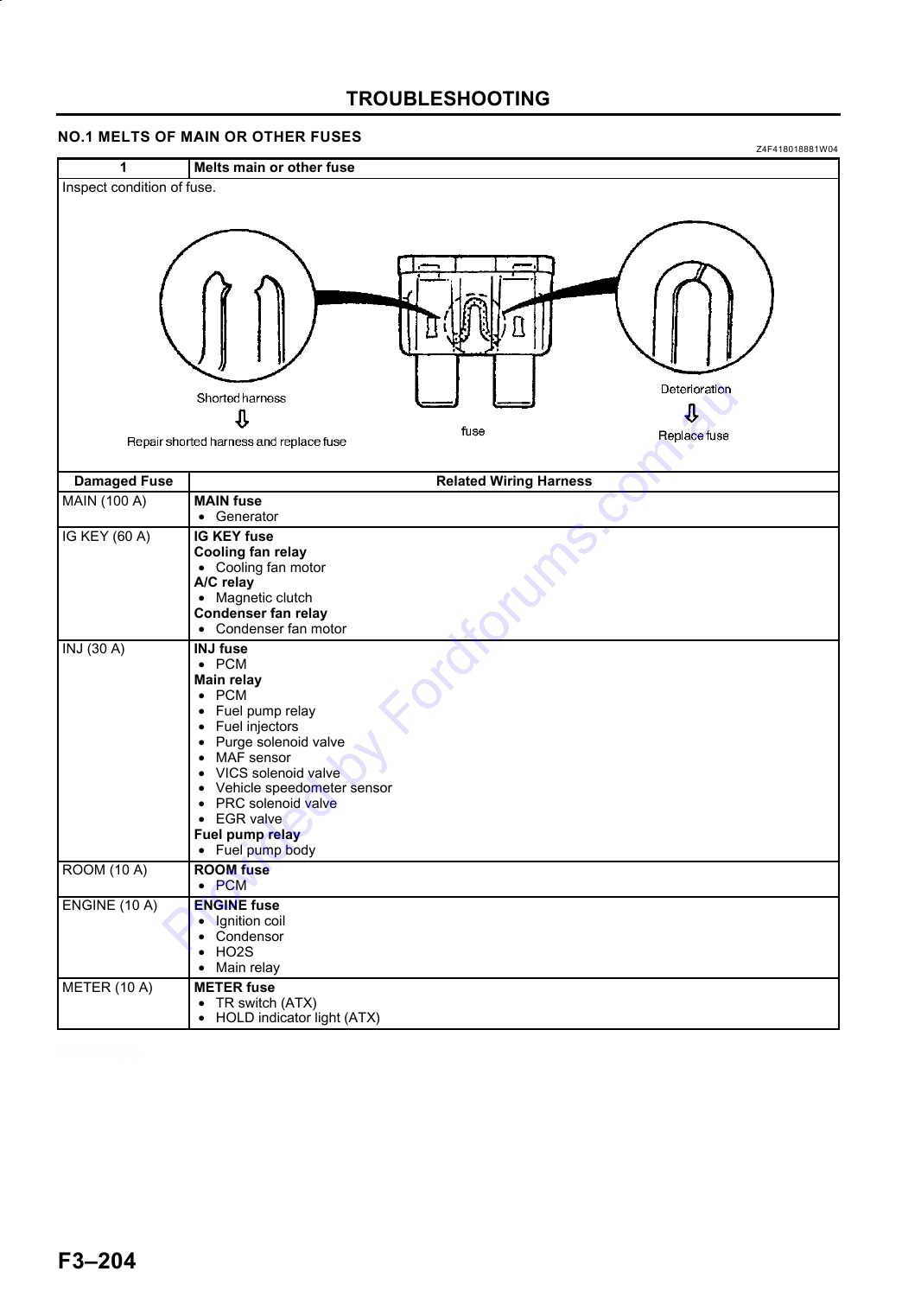

NO.1 MELTS OF MAIN OR OTHER FUSES . F3-204

DTC P0032 (FS) .............................................. F3-93

NO.2 WILL NOT CRANK ............................... F3-205

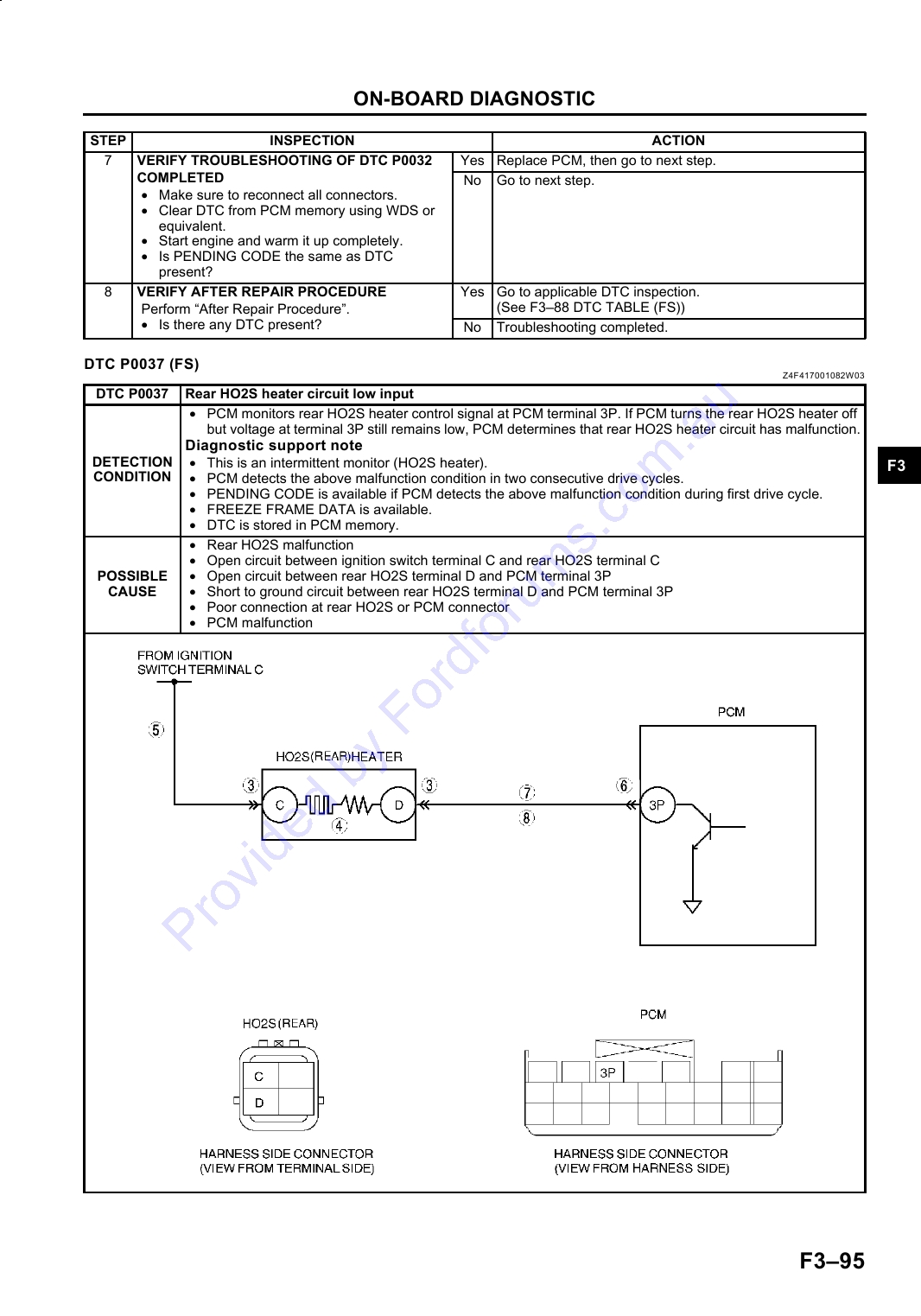

DTC P0037 (FS) .............................................. F3-95

NO.3 HARD START/LONG CRANK/ERRATIC

DTC P0038 (FS) .............................................. F3-97

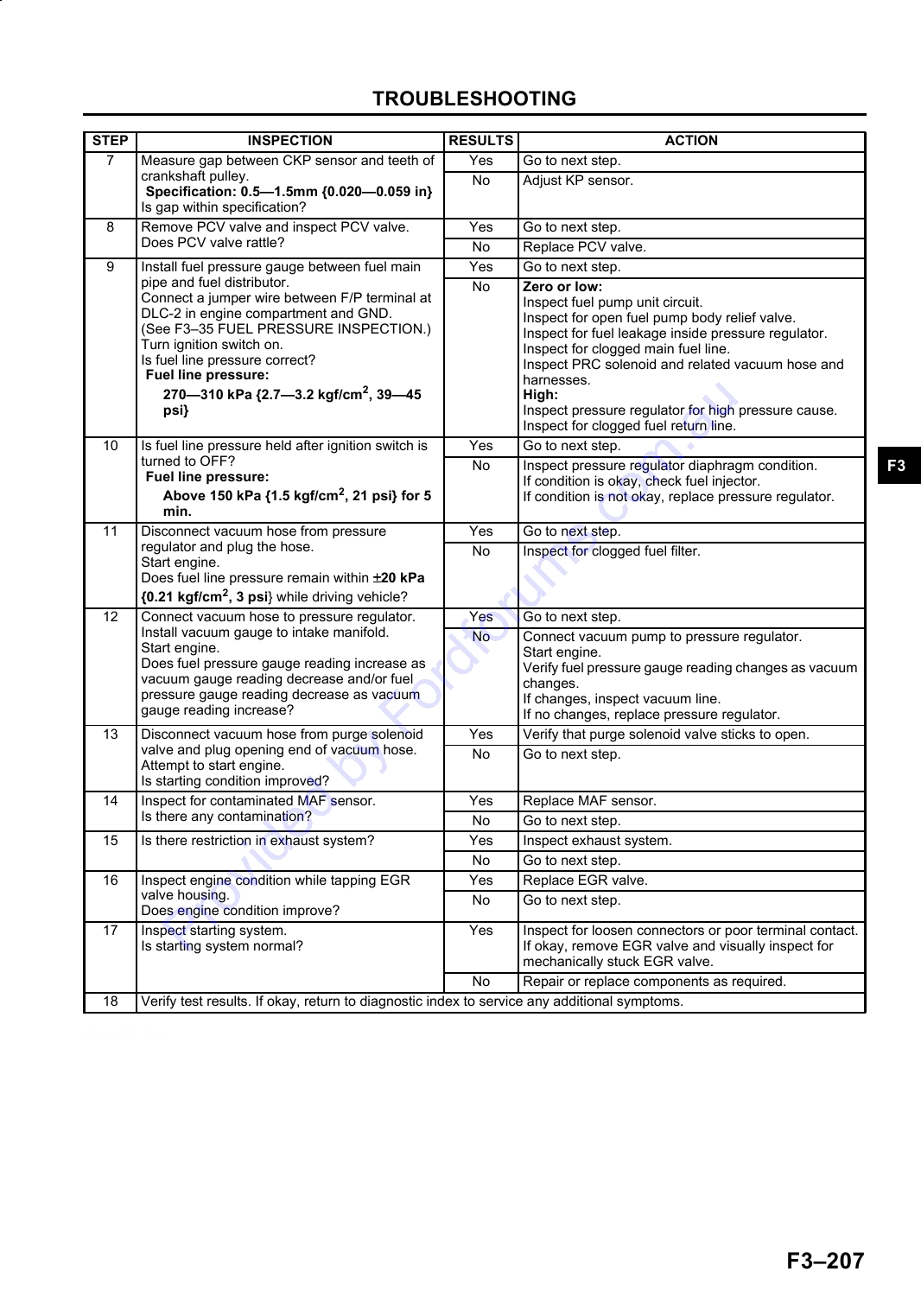

START/ERRATIC CRANK .......................... F3-206

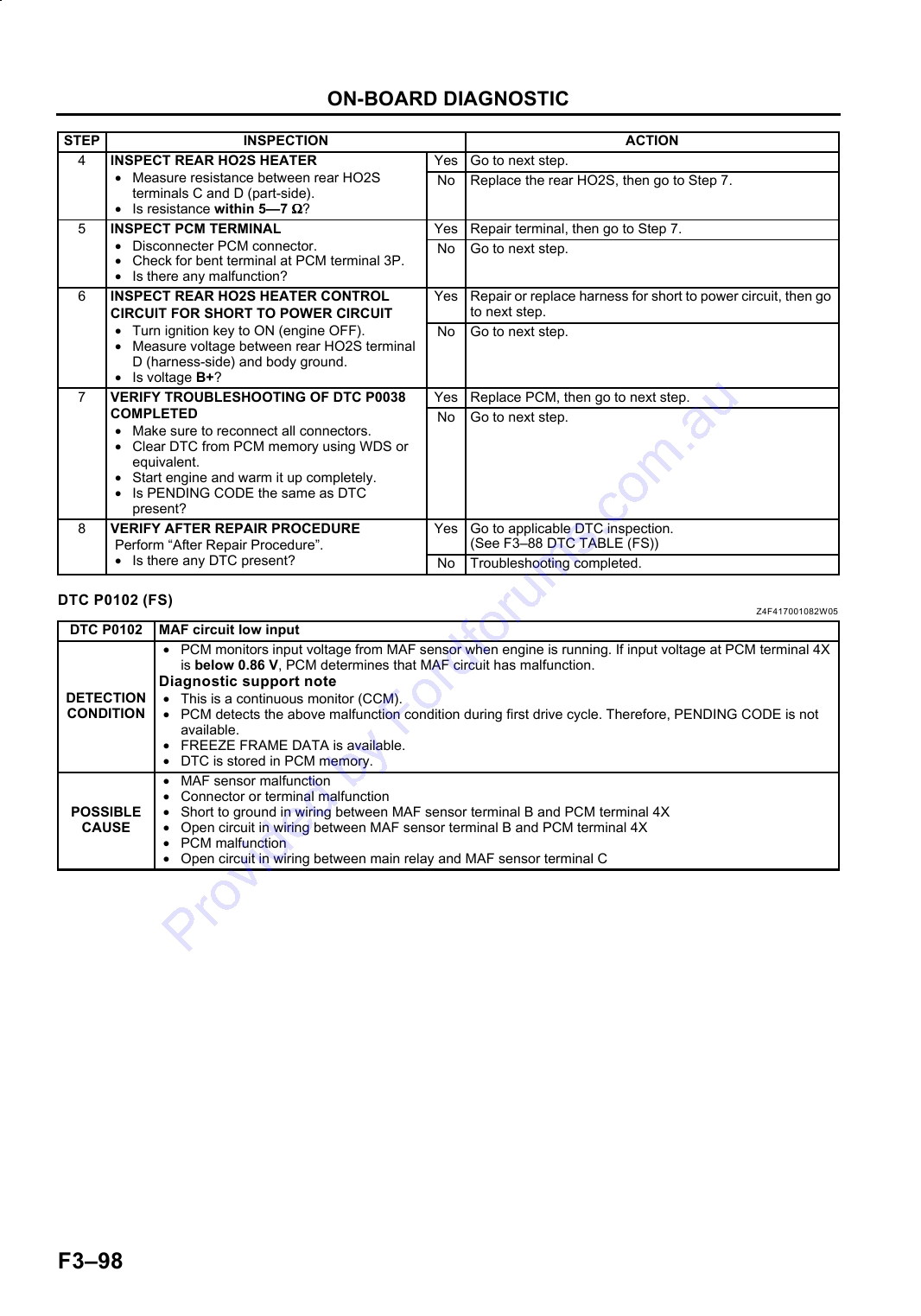

DTC P0102 (FS) .............................................. F3-98

NO.4 ENGINE STALLS-AFTER START/AT

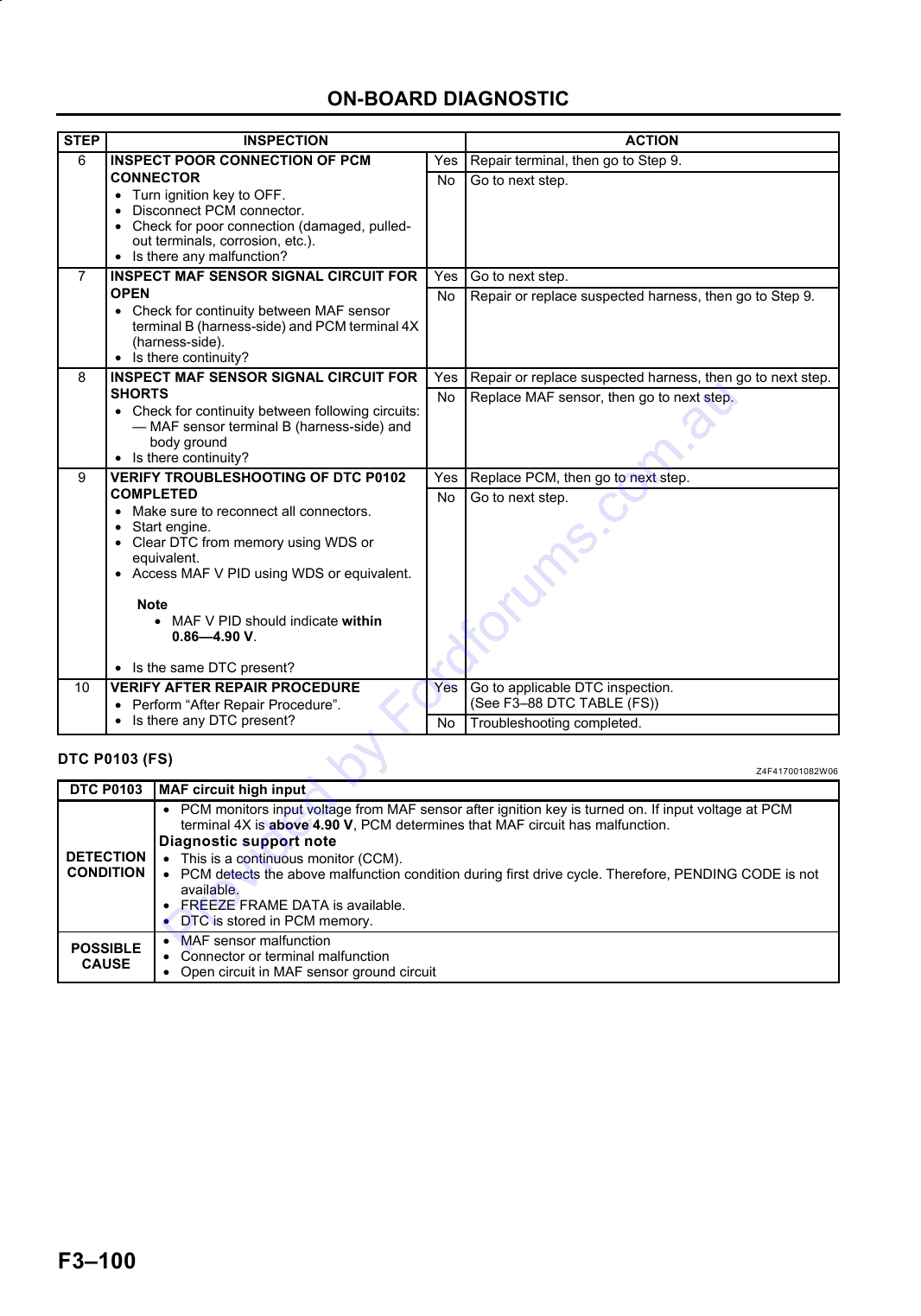

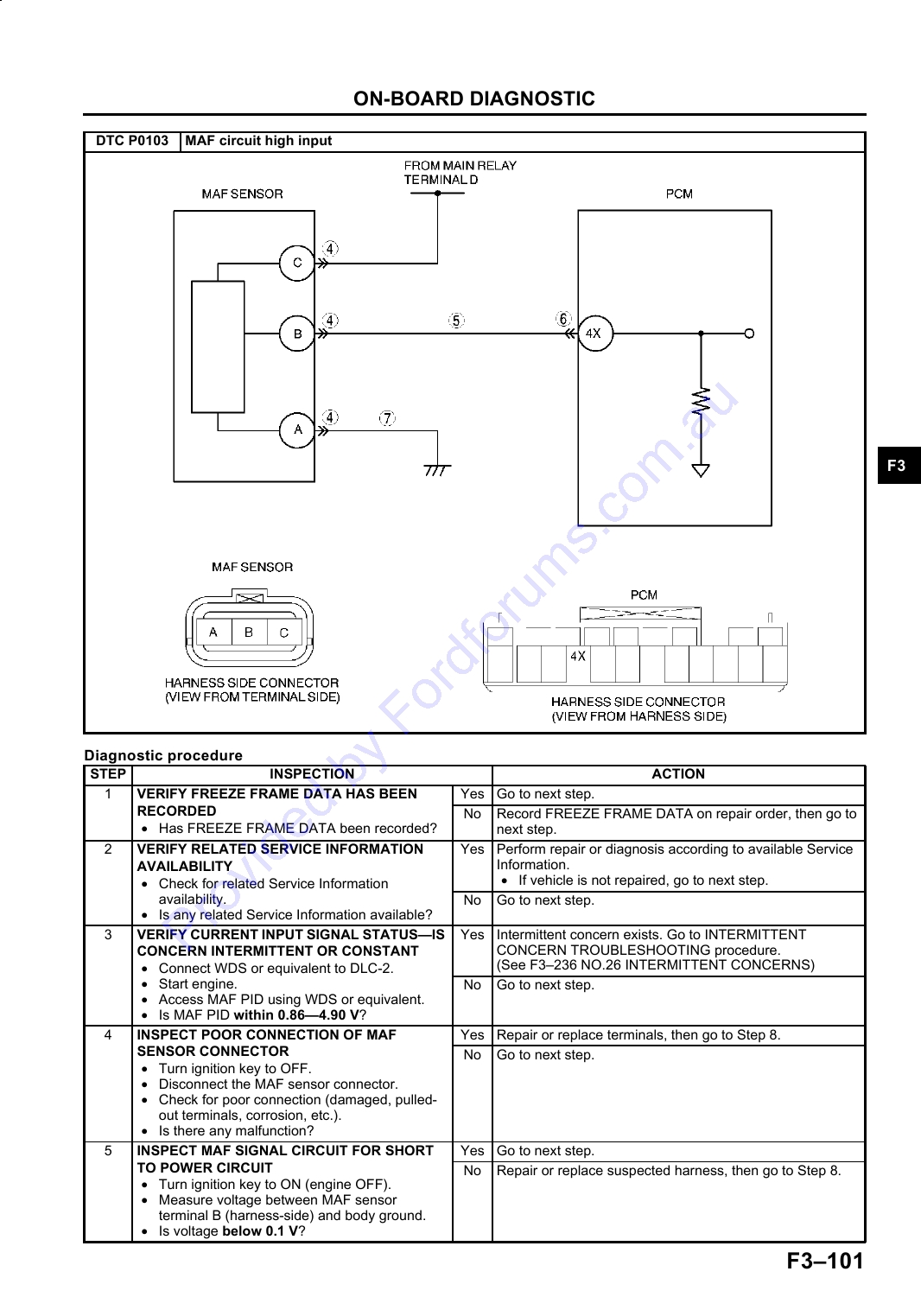

DTC P0103 (FS) ............................................ F3-100

IDLE ............................................................ F3-208

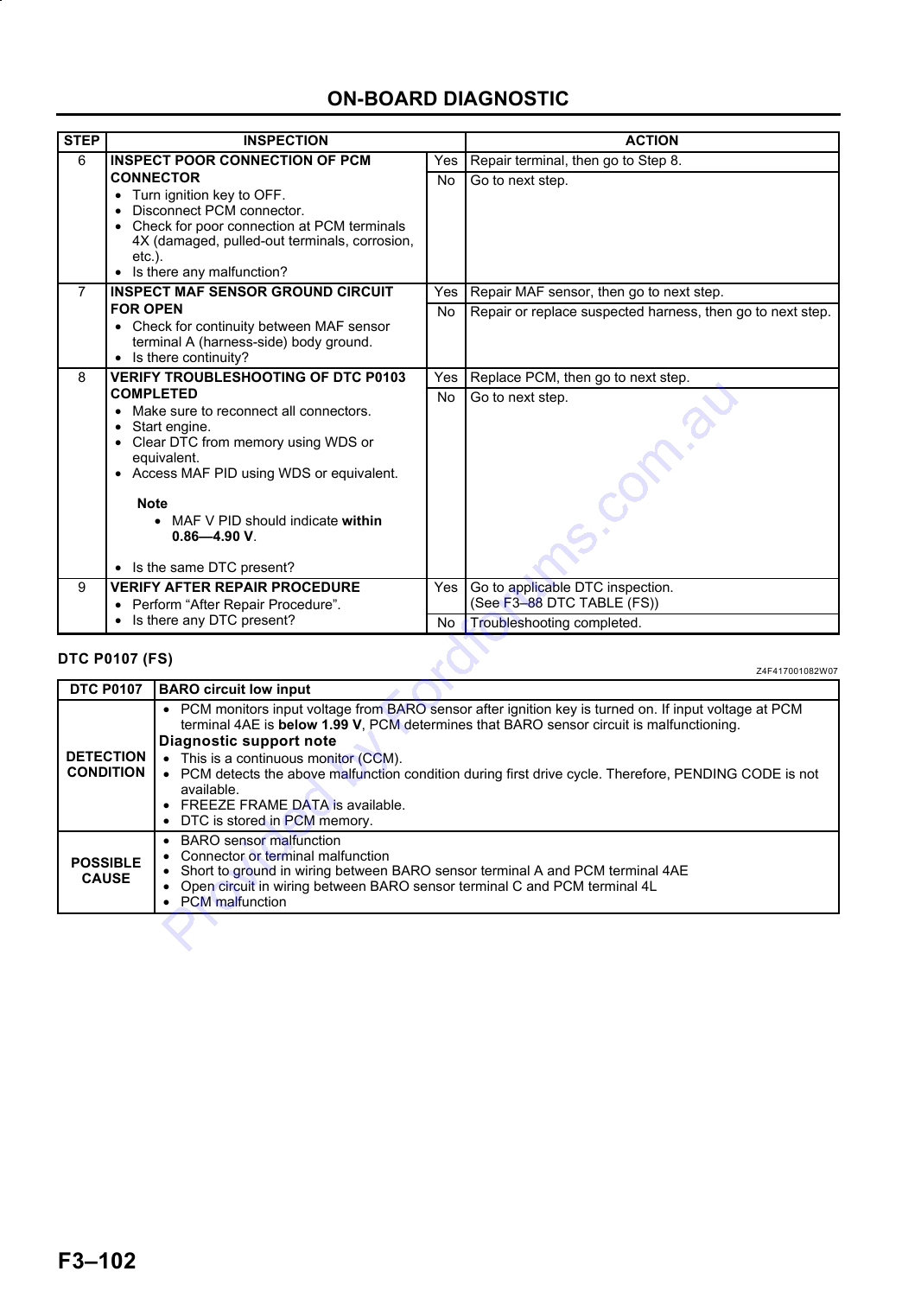

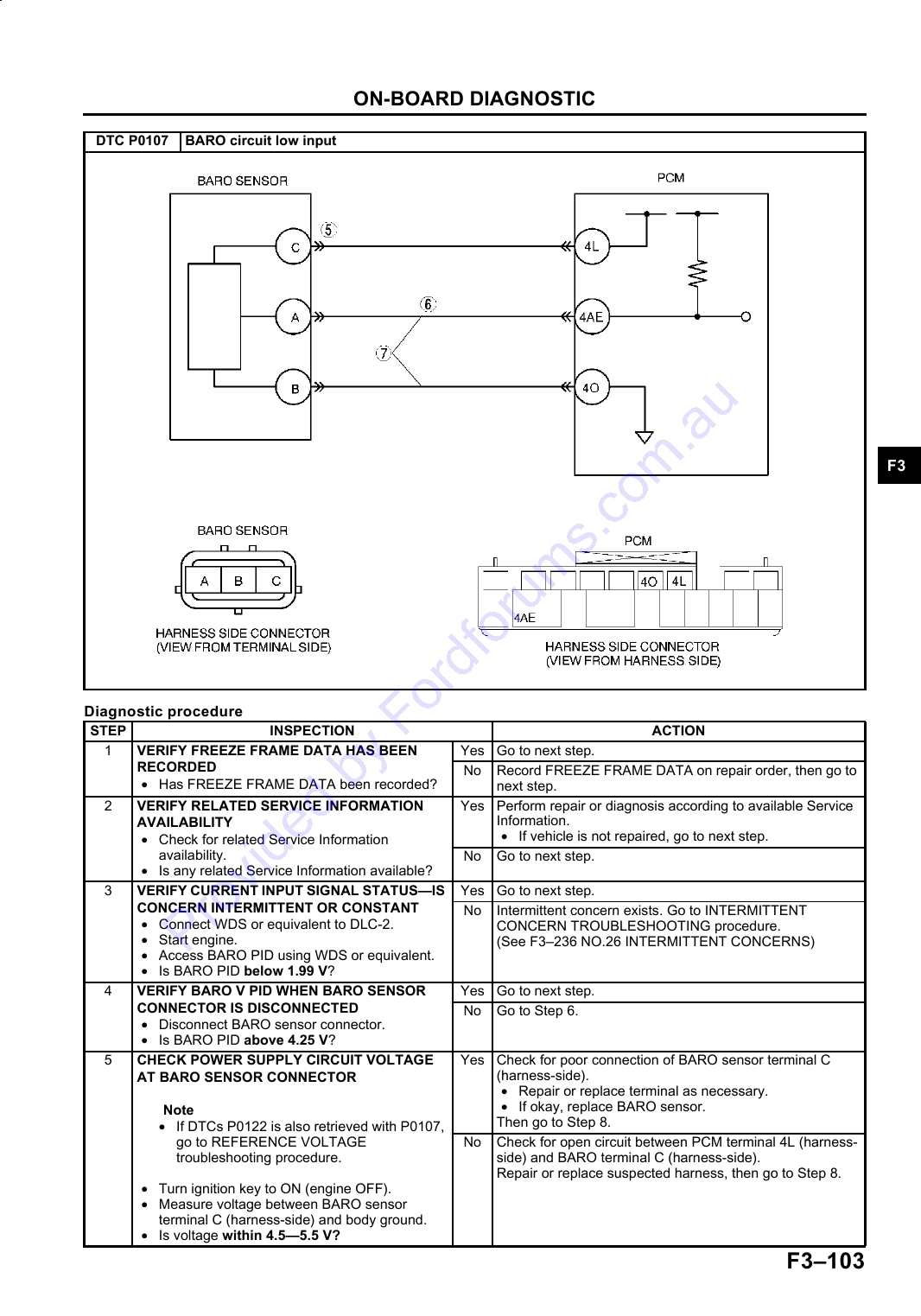

DTC P0107 (FS) ............................................ F3-102

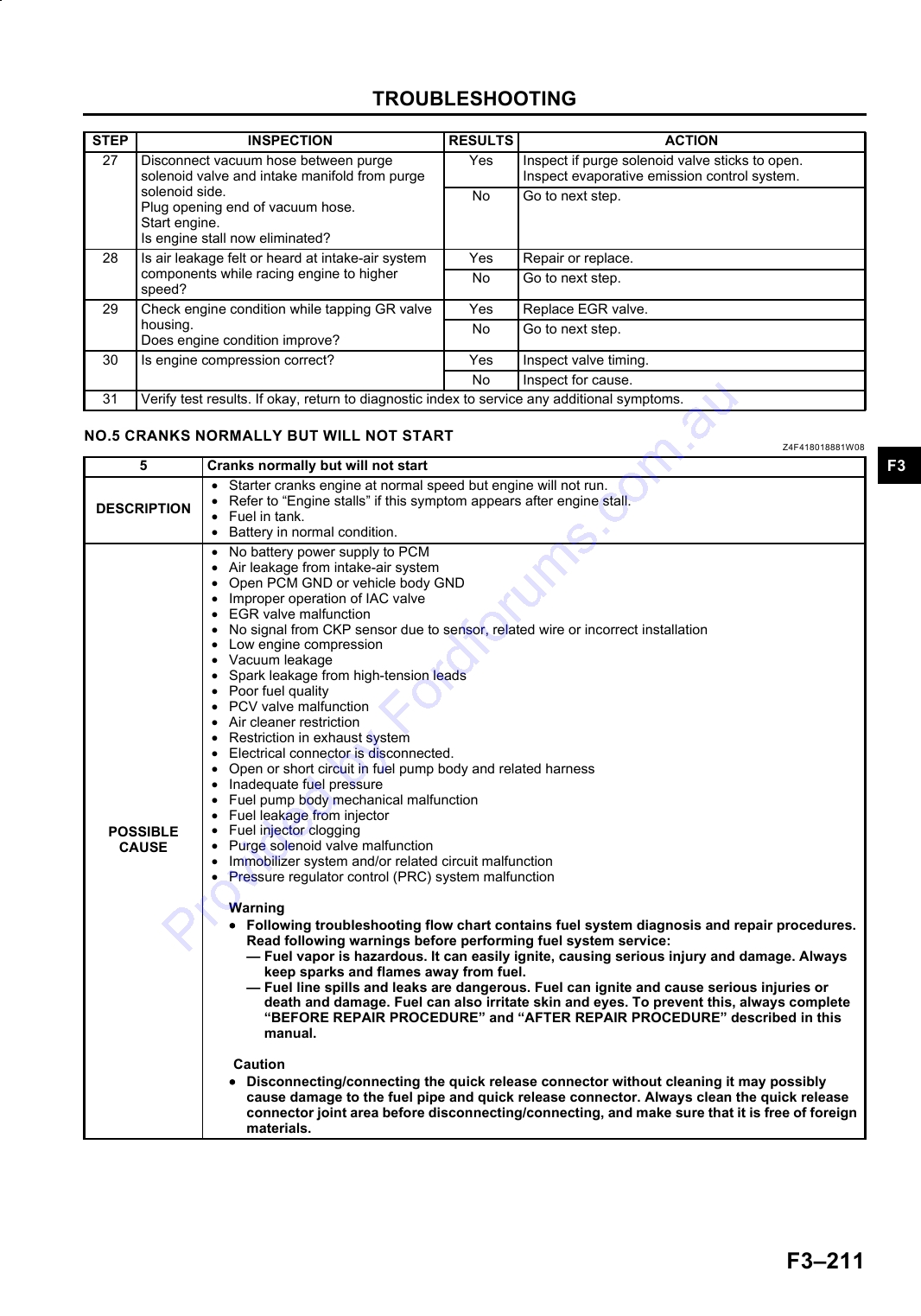

NO.5 CRANKS NORMALLY BUT WILL

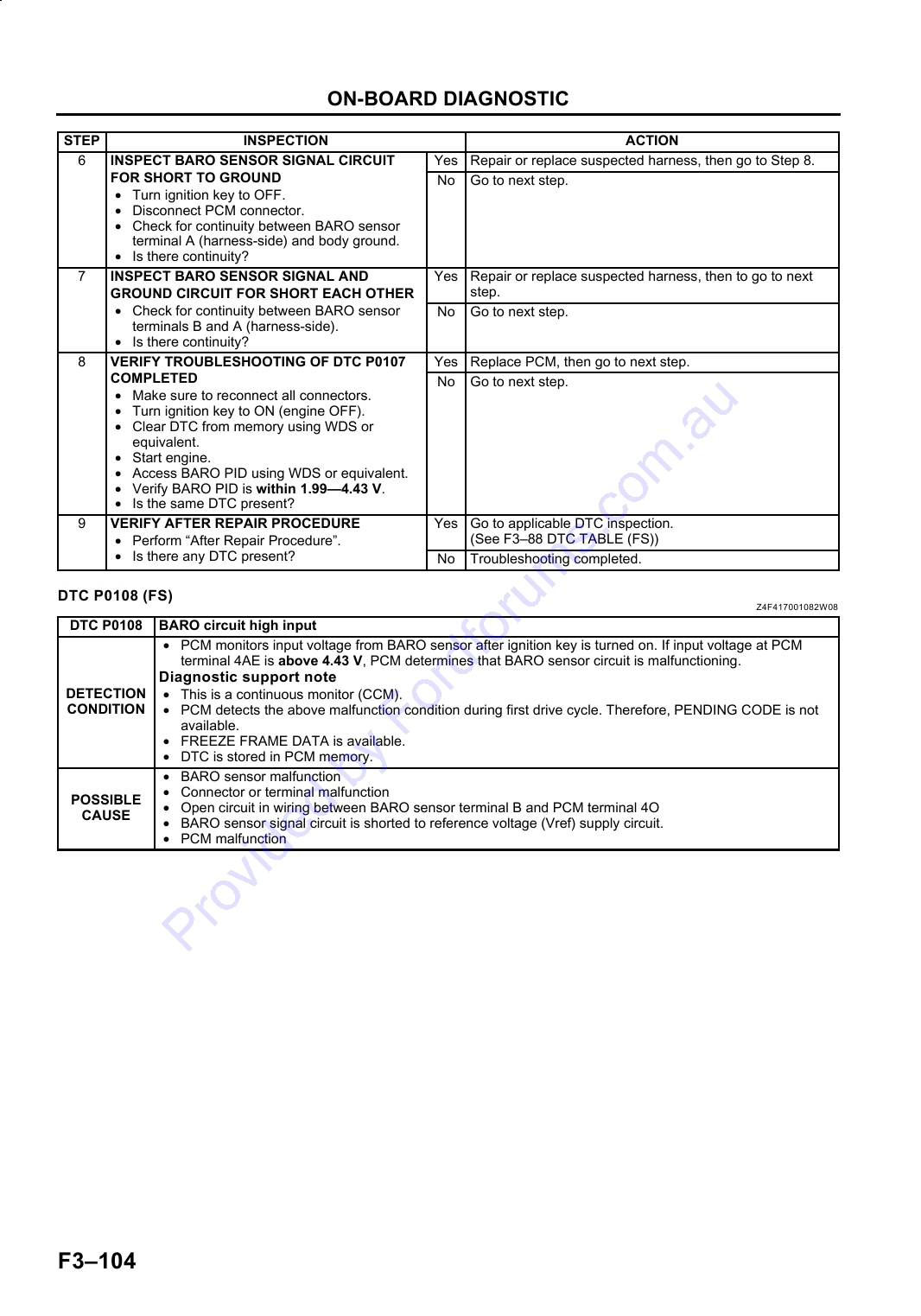

DTC P0108 (FS) ............................................ F3-104

NOT START................................................ F3-211

DTC P0111 (FS) ............................................ F3-106

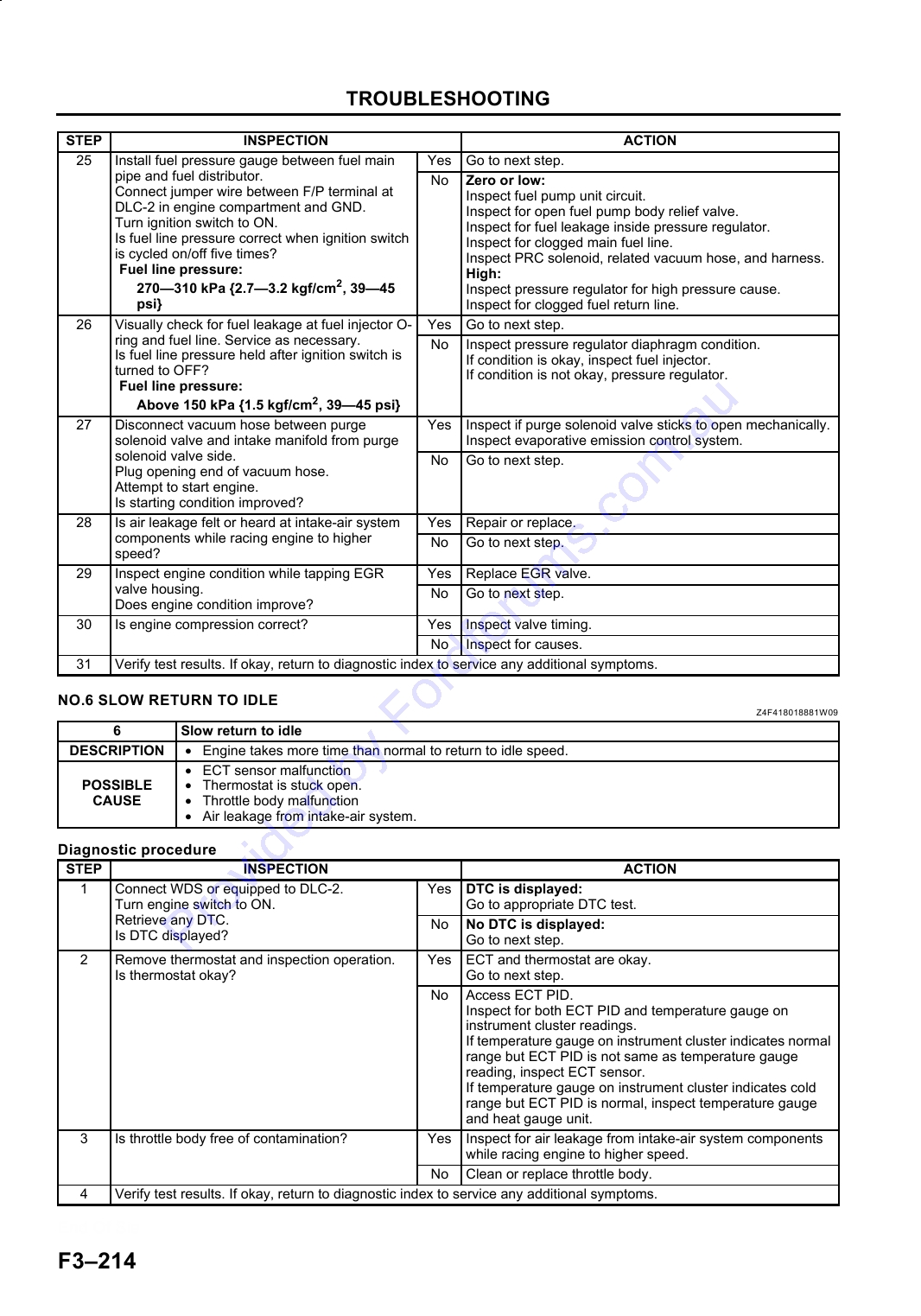

NO.6 SLOW RETURN TO IDLE .................... F3-214

DTC P0112 (FS) ............................................ F3-107

NO.7 ENGINE RUNS ROUGH/ROLLING

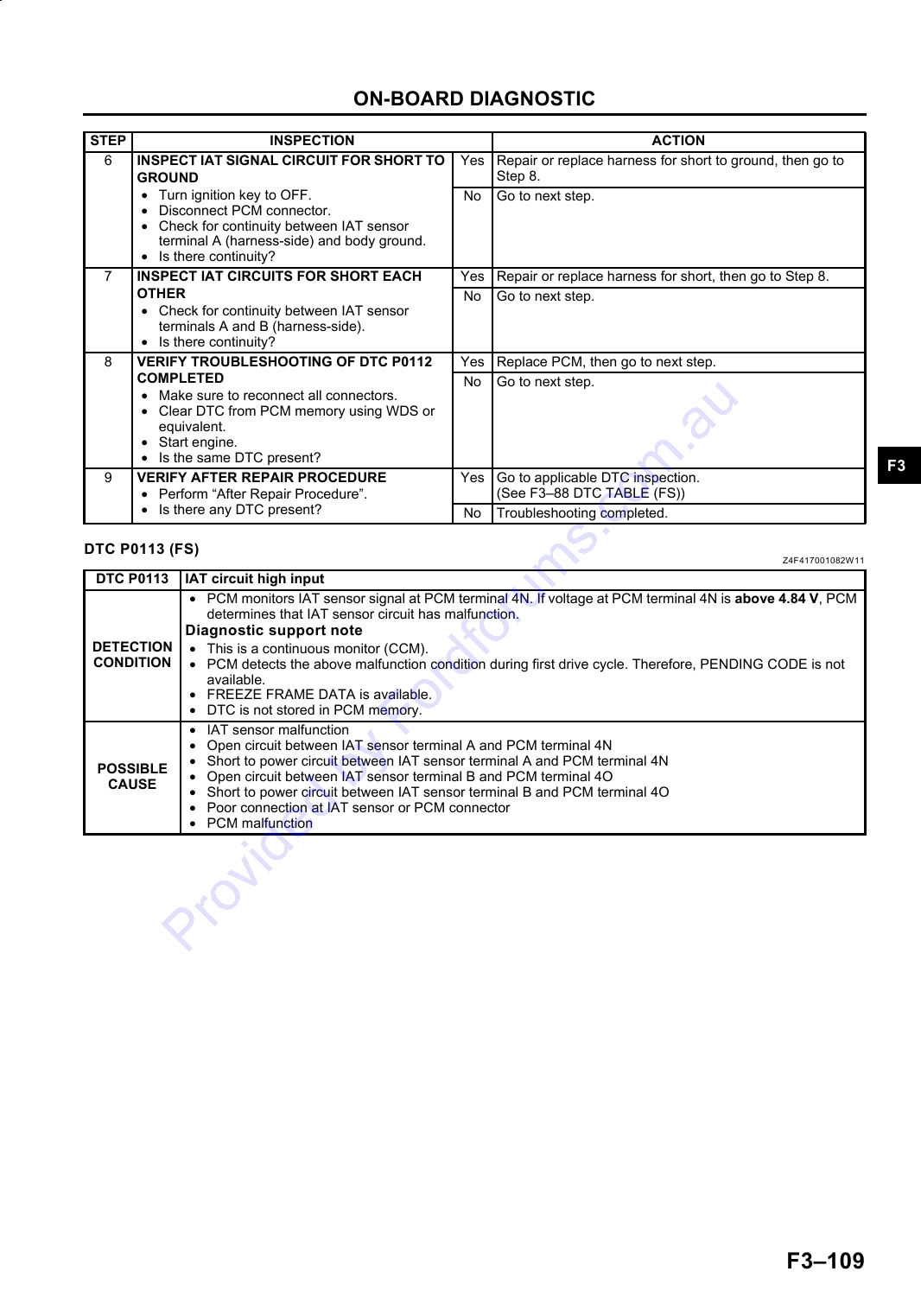

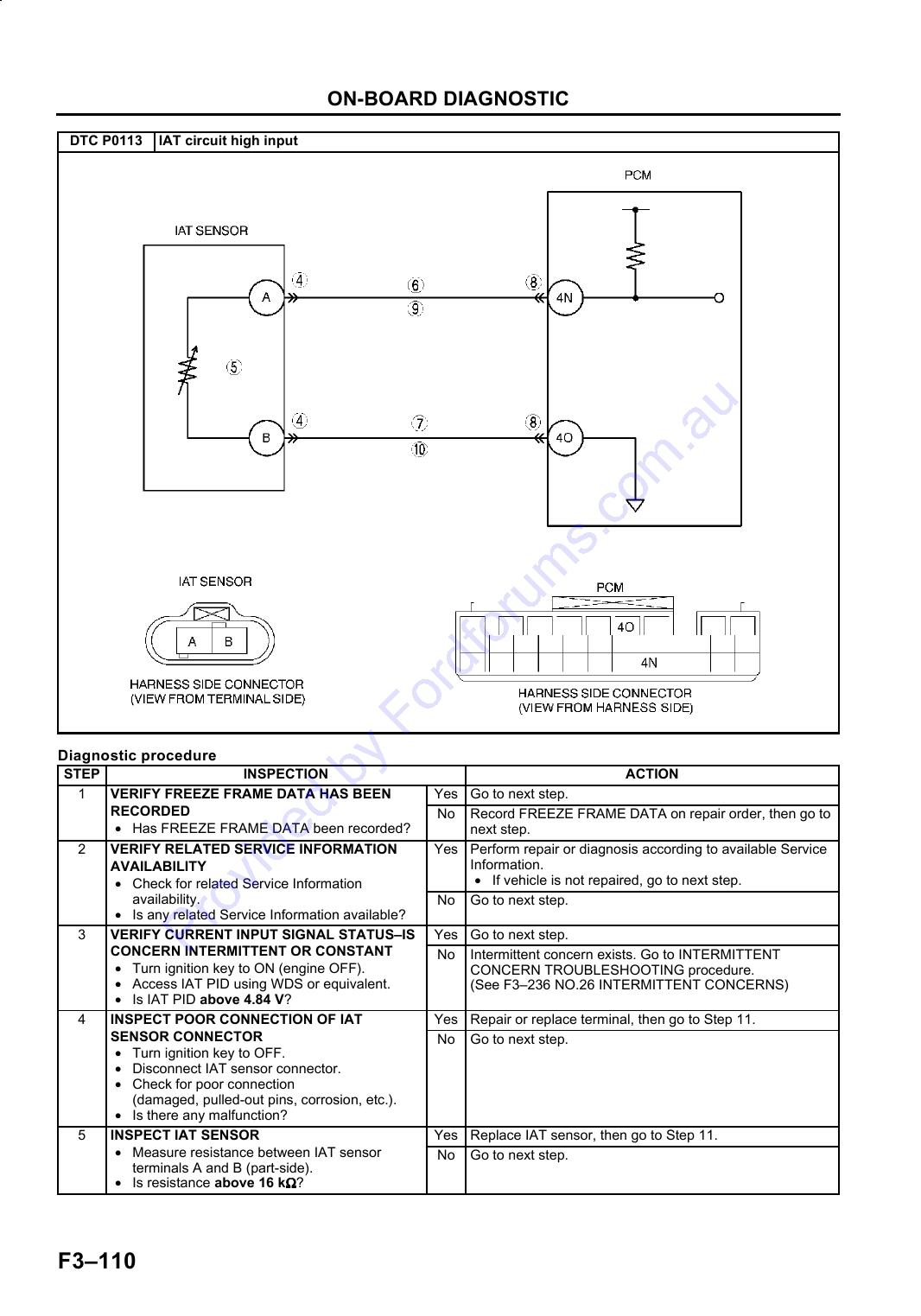

DTC P0113 (FS) ............................................ F3-109

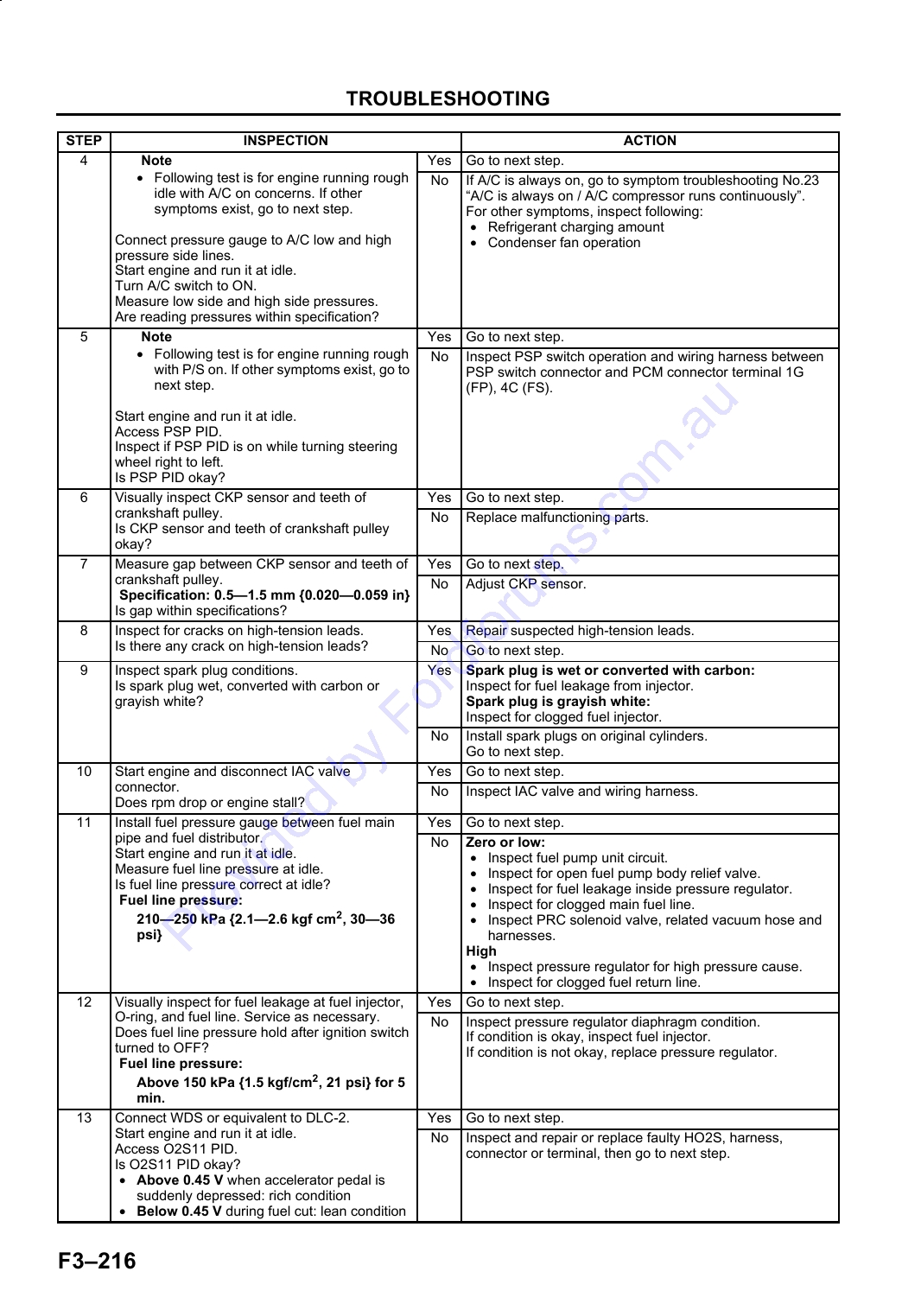

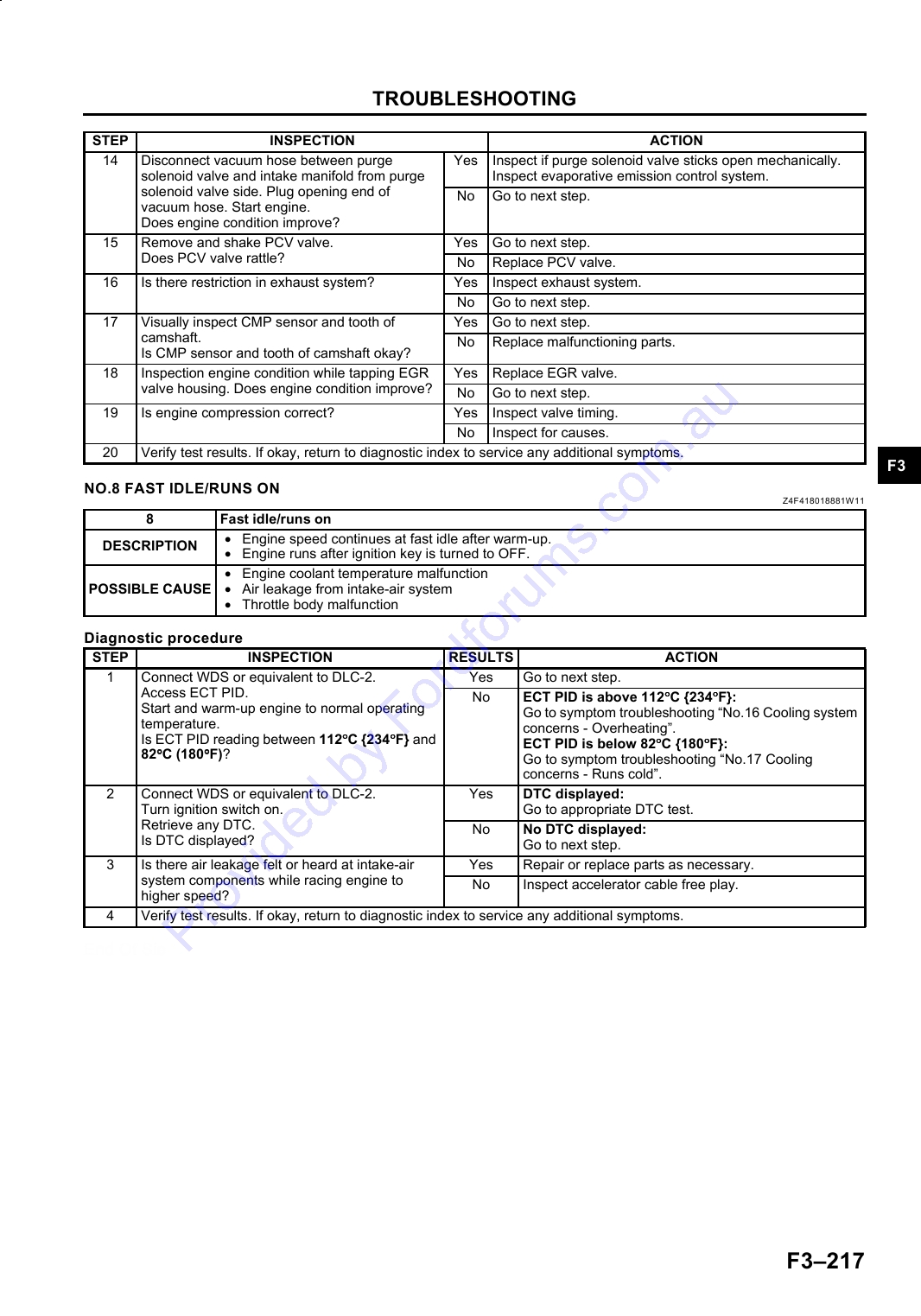

IDLE ............................................................ F3-215

DTC P0117 (FS) ............................................ F3-111

NO.8 FAST IDLE/RUNS ON .......................... F3-217

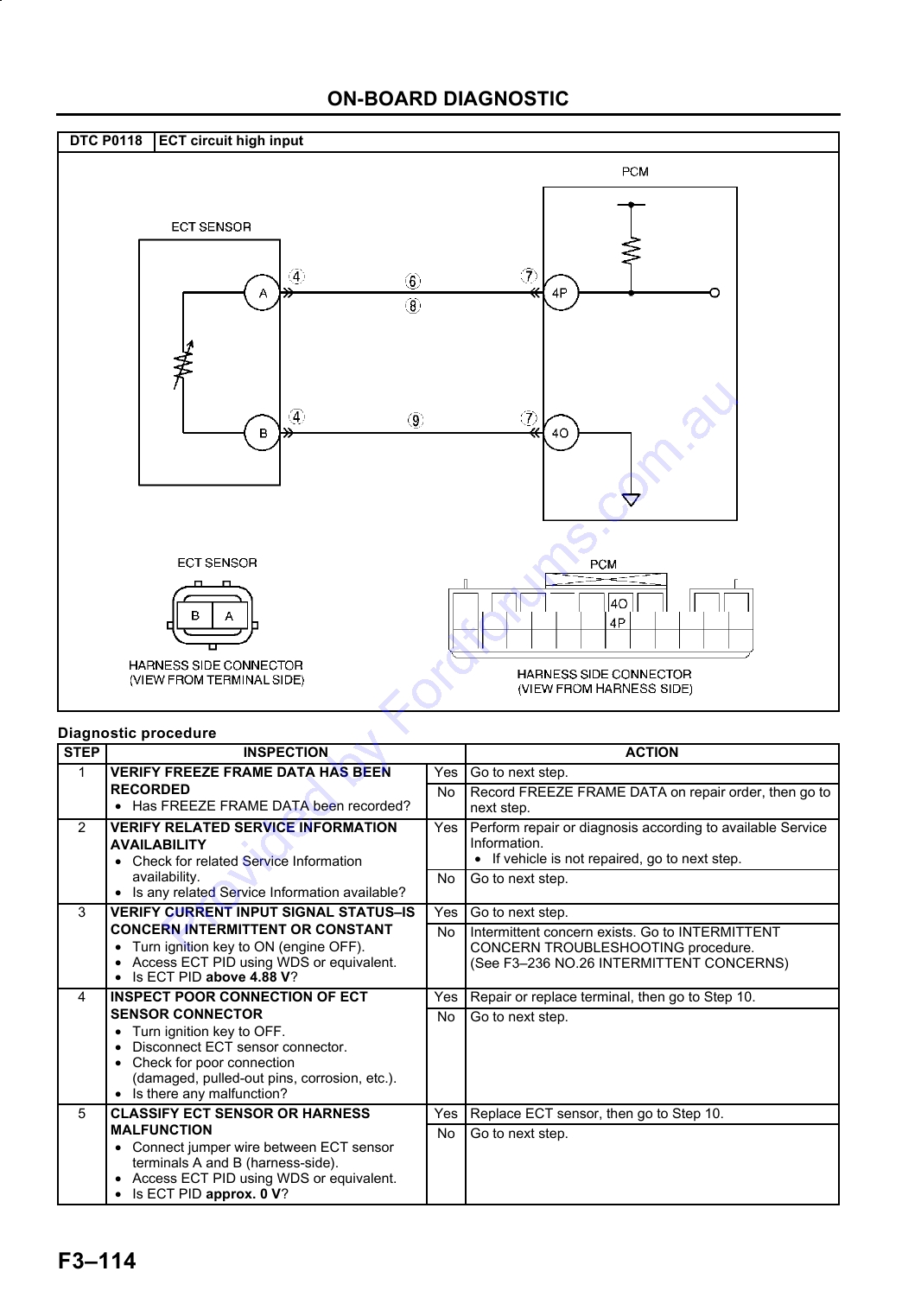

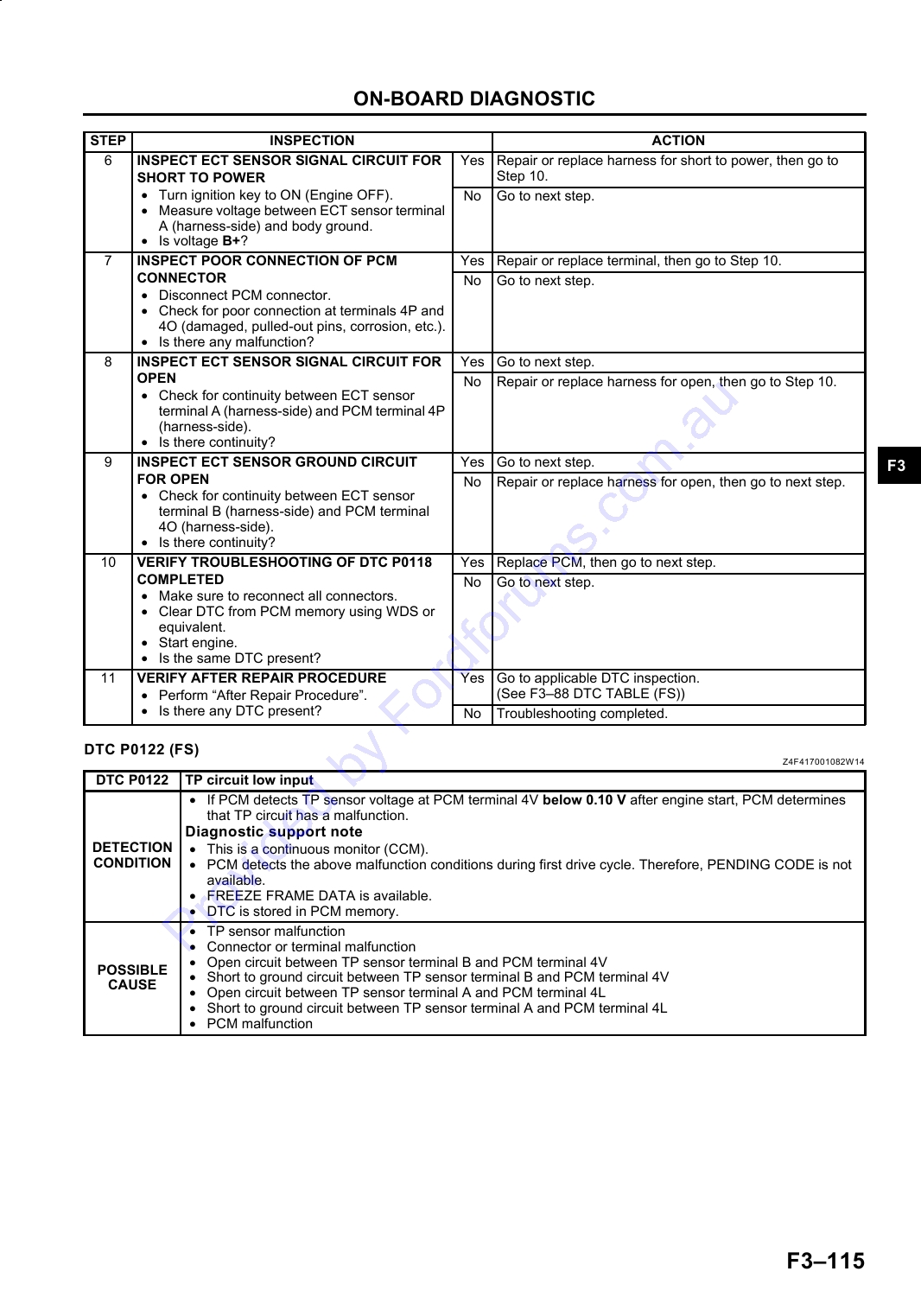

DTC P0118 (FS) ............................................ F3-113

NO.9 LOW IDLE/STALLS DURING

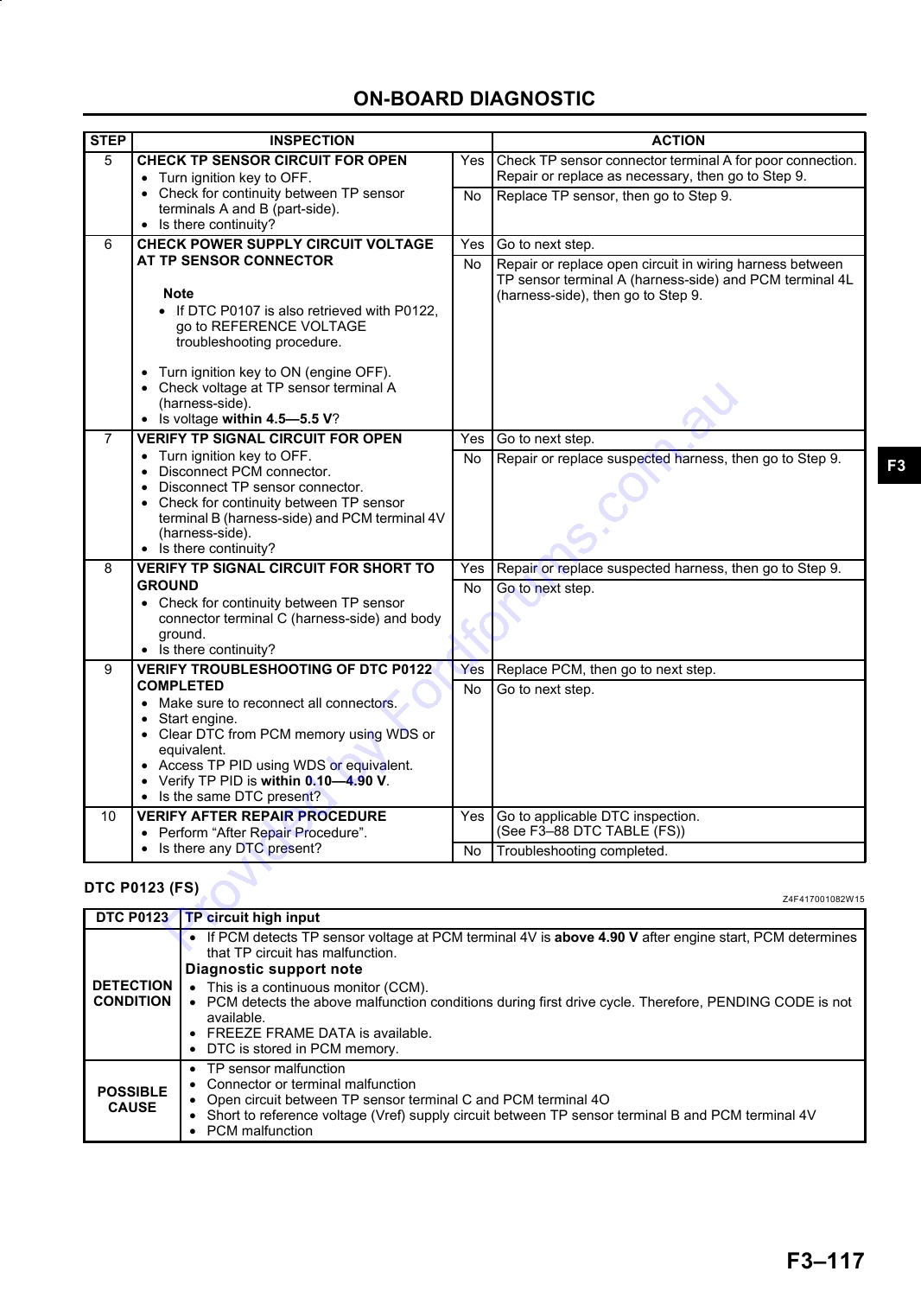

DTC P0122 (FS) ............................................ F3-115

DECELERATION ........................................ F3-218

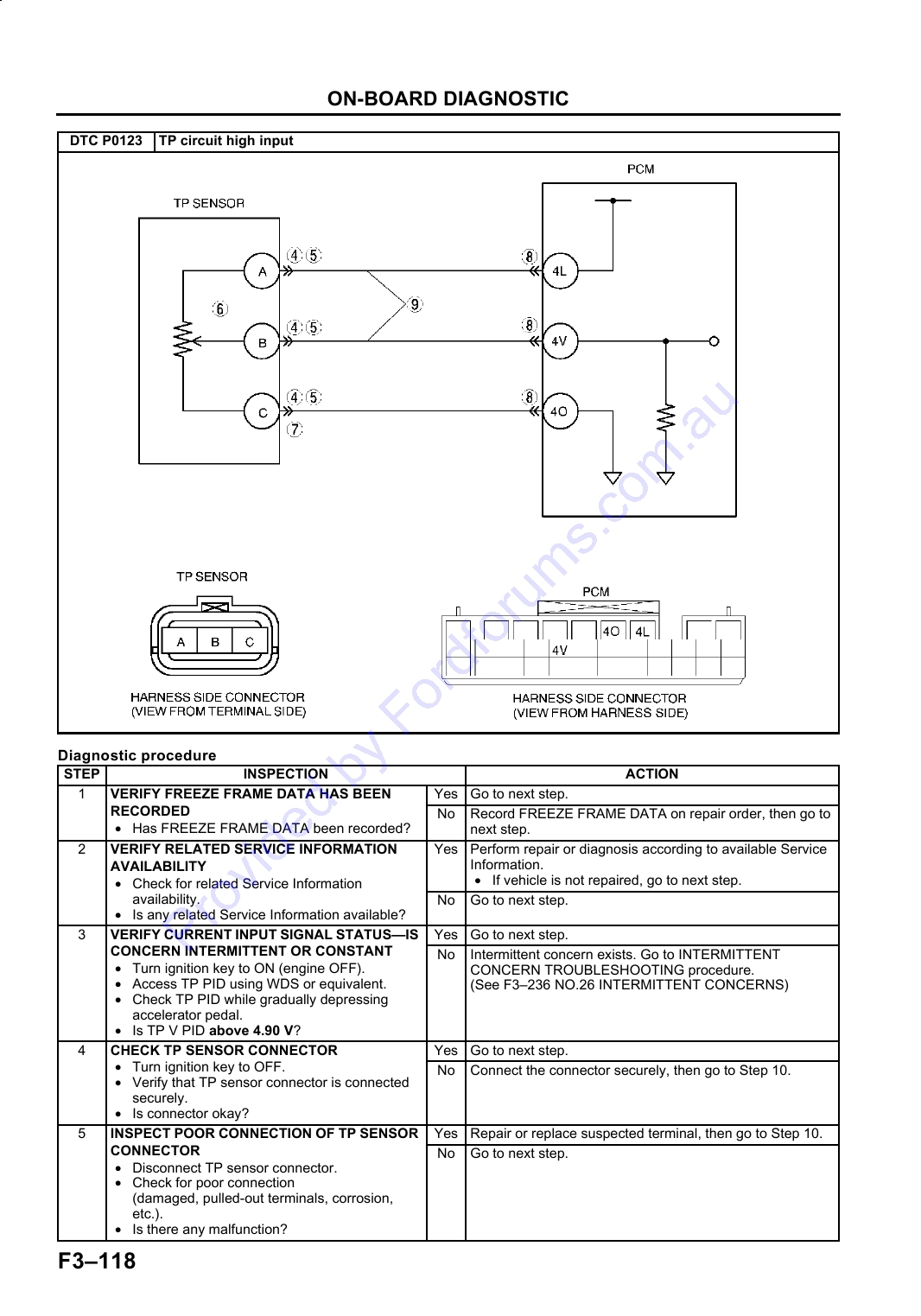

DTC P0123 (FS) ............................................ F3-117

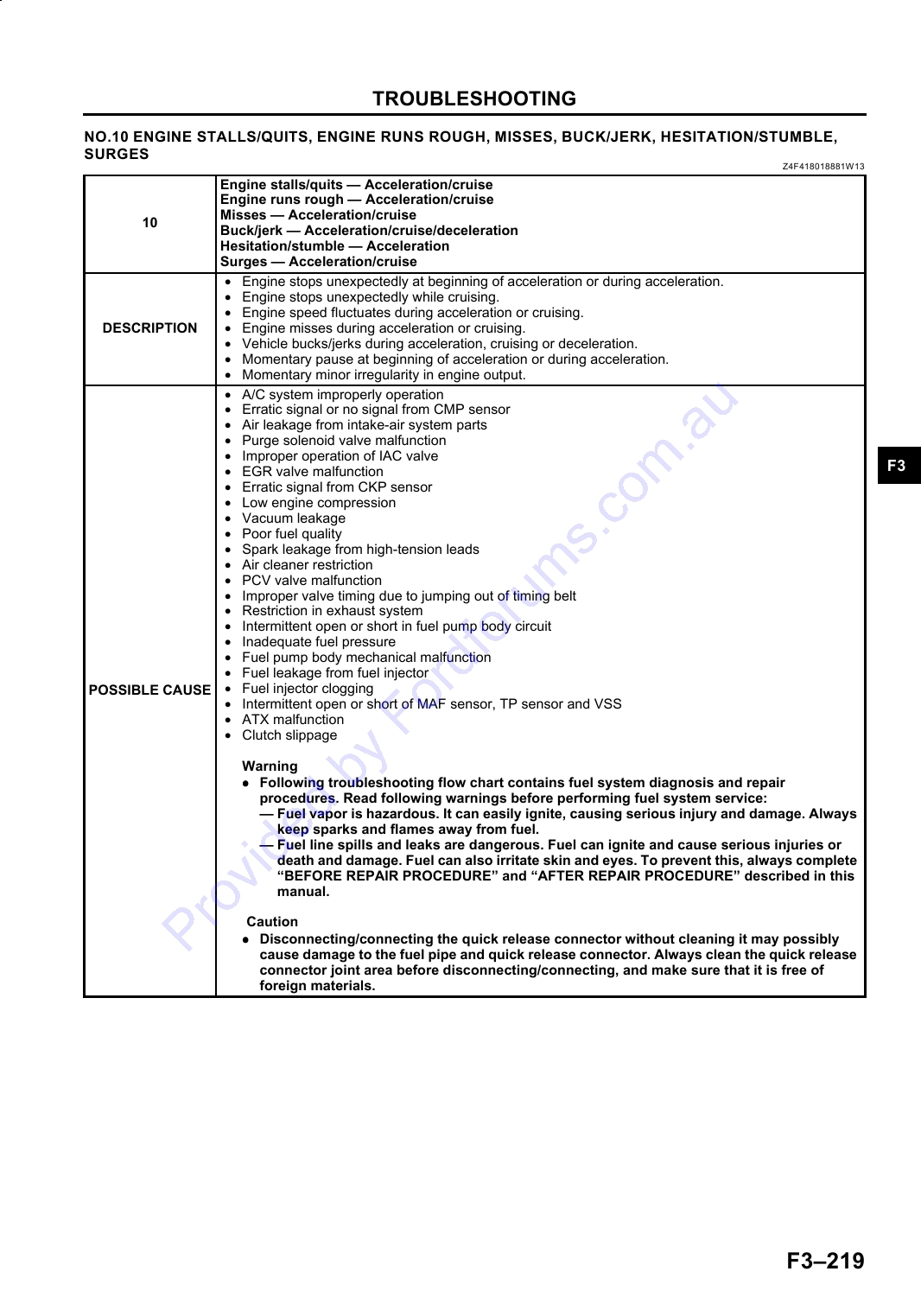

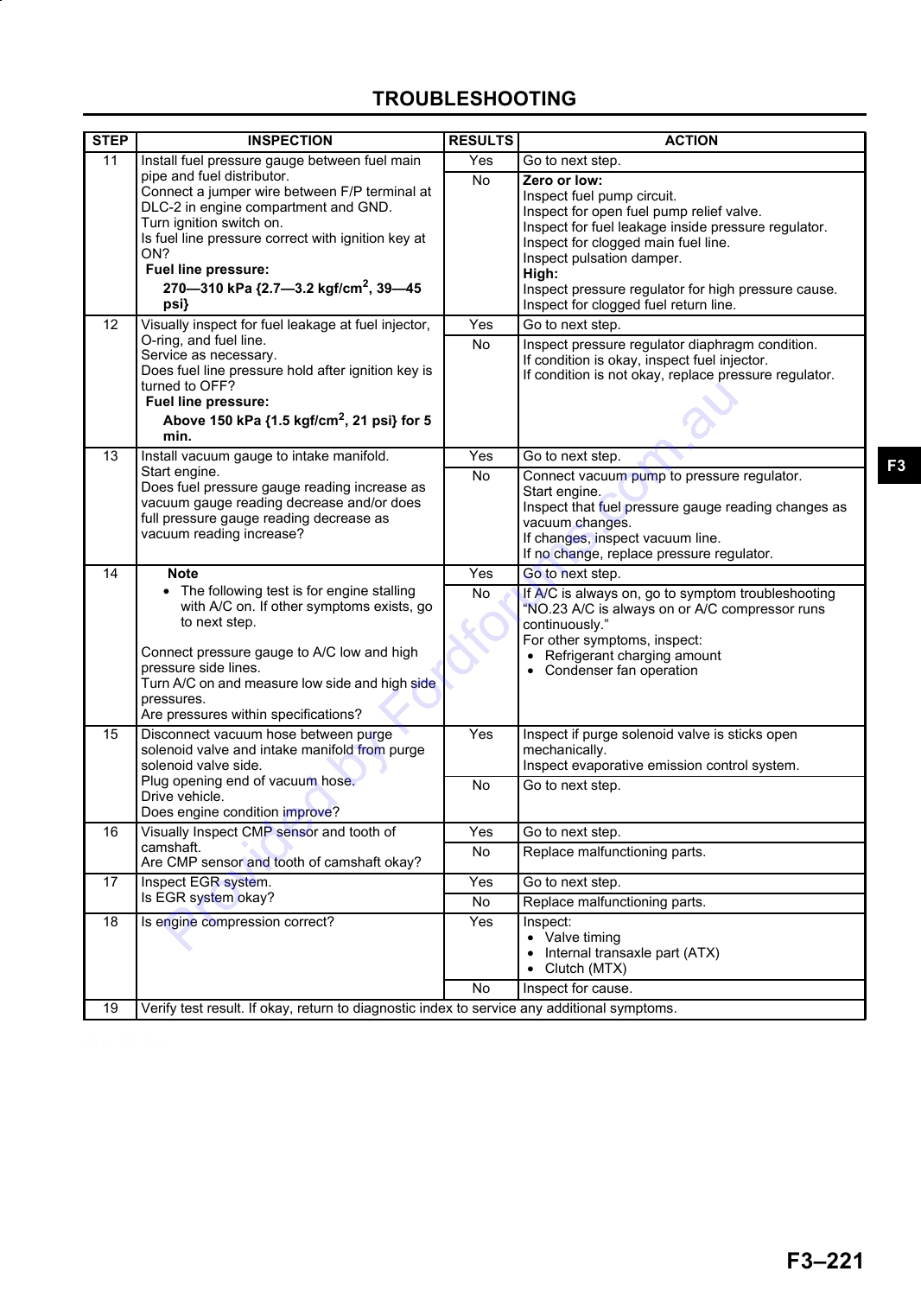

NO.10 ENGINE STALLS/QUITS, ENGINE

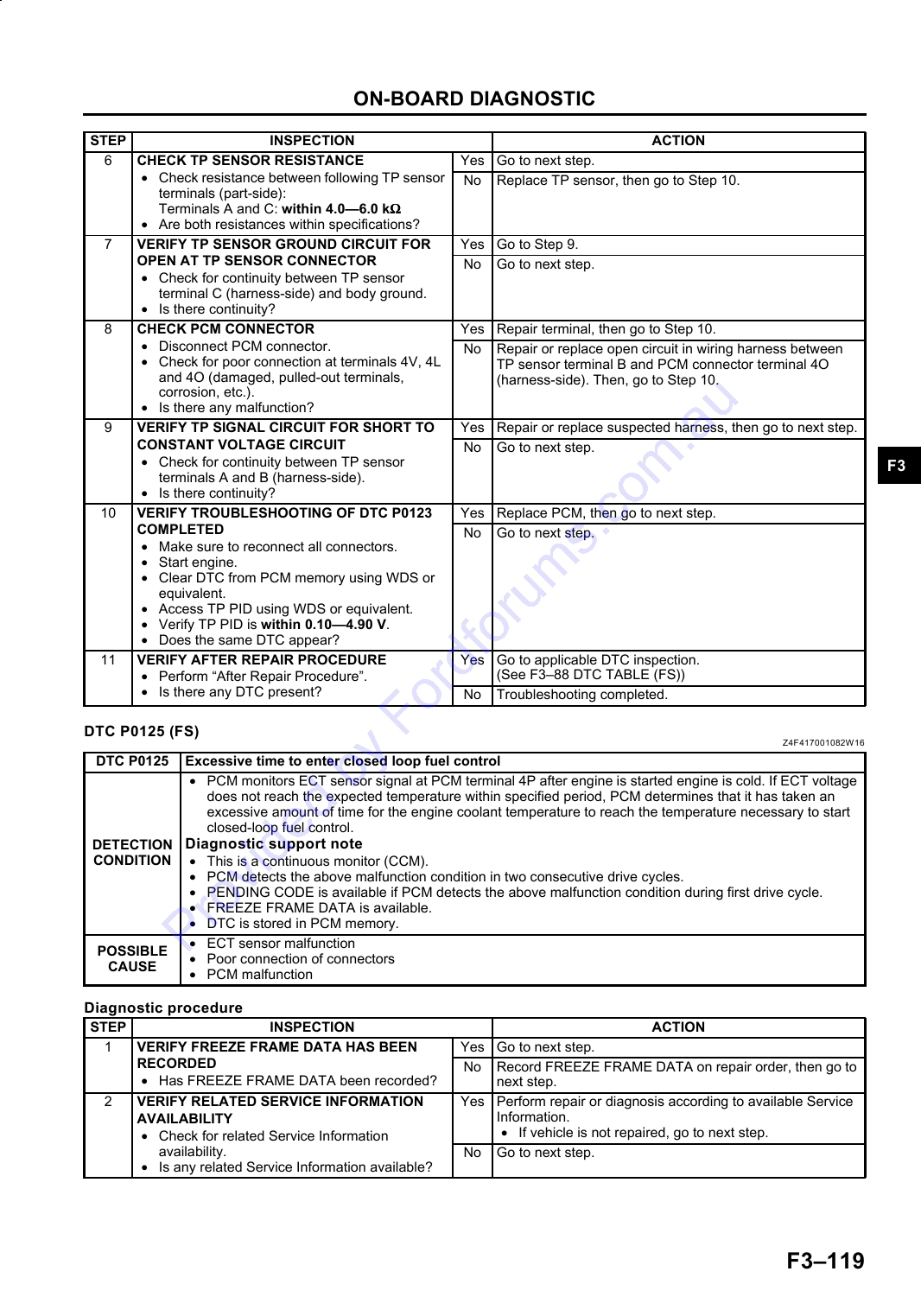

DTC P0125 (FS) ............................................ F3-119

RUNS ROUGH, MISSES, BUCK/JERK,

DTC P0130 (FS) ............................................ F3-120

HESITATION/STUMBLE, SURGES ........... F3-219

DTC P0134 (FS) ............................................ F3-123

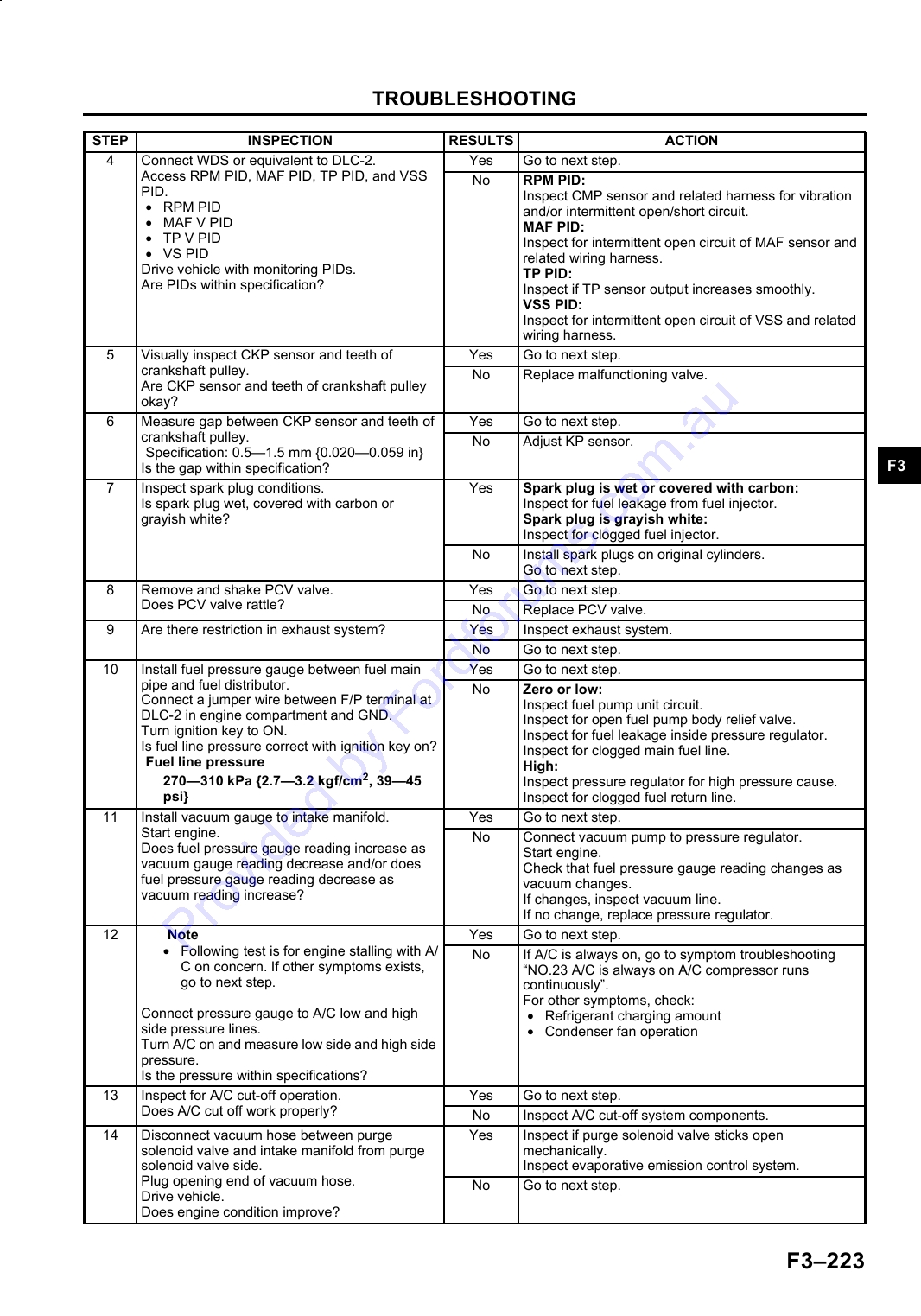

NO.11 LACK/LOSS OF

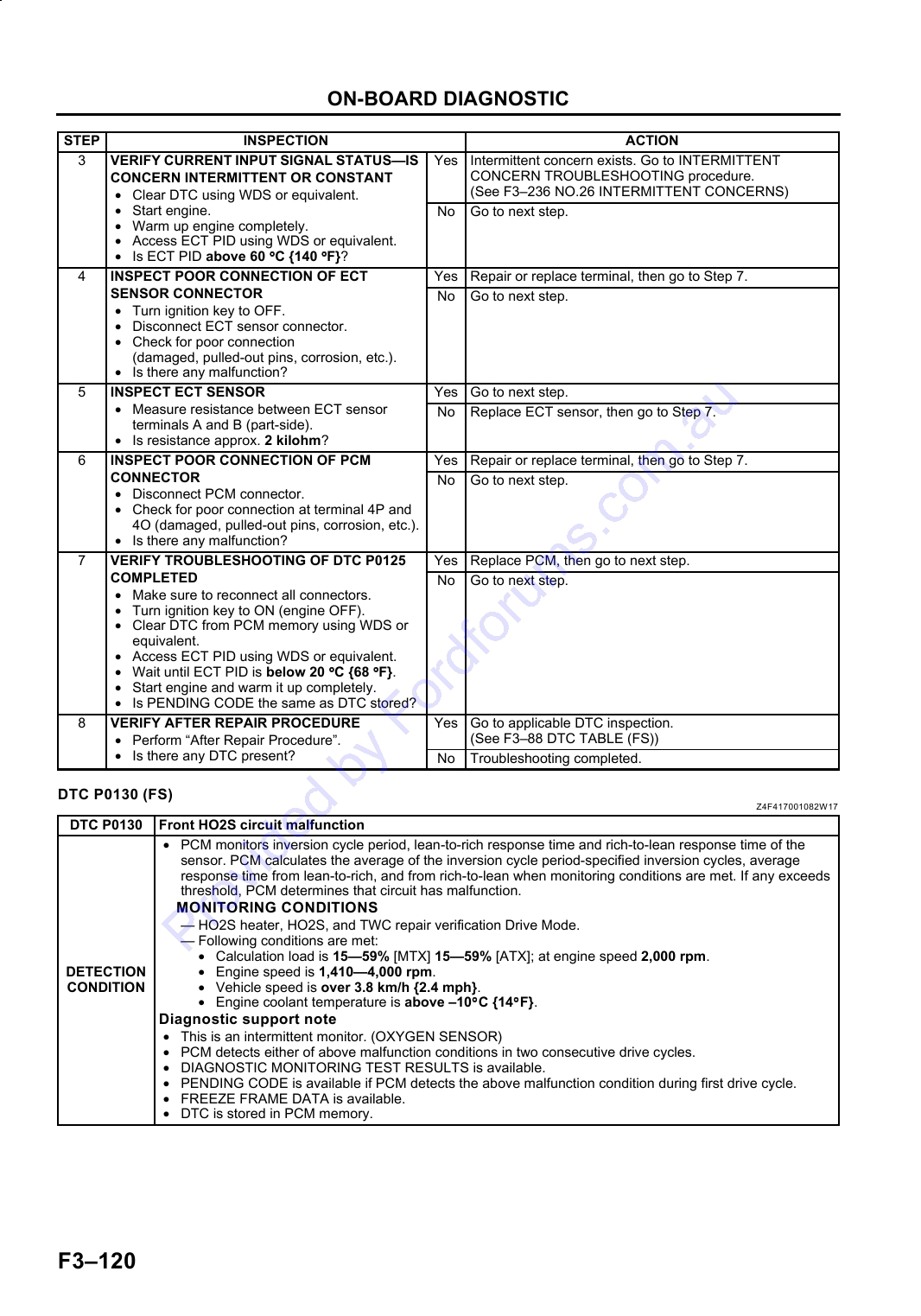

DTC P0138 (FS) ............................................ F3-125

POWER-ACCELERATION/CRUISE ........... F3-222

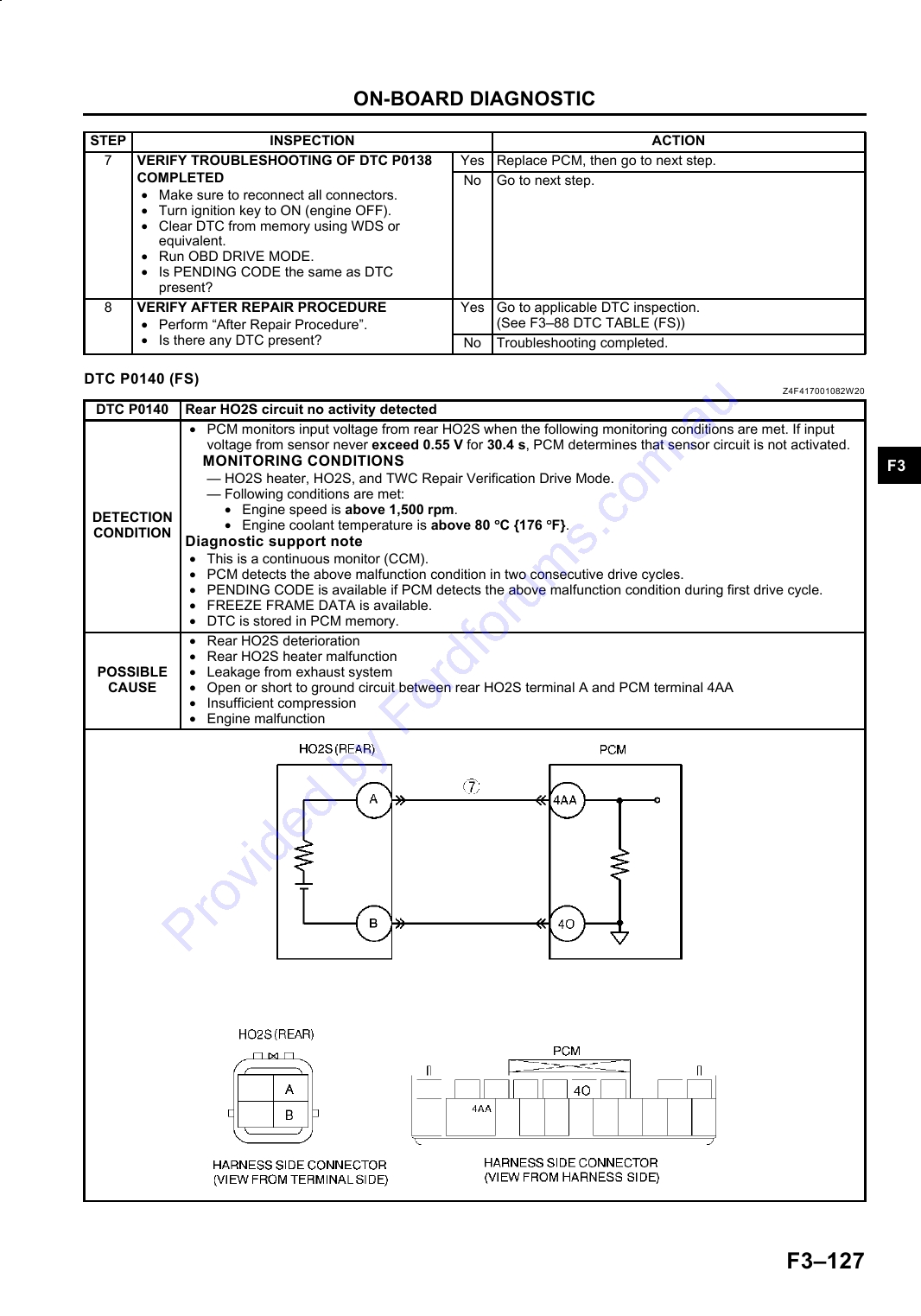

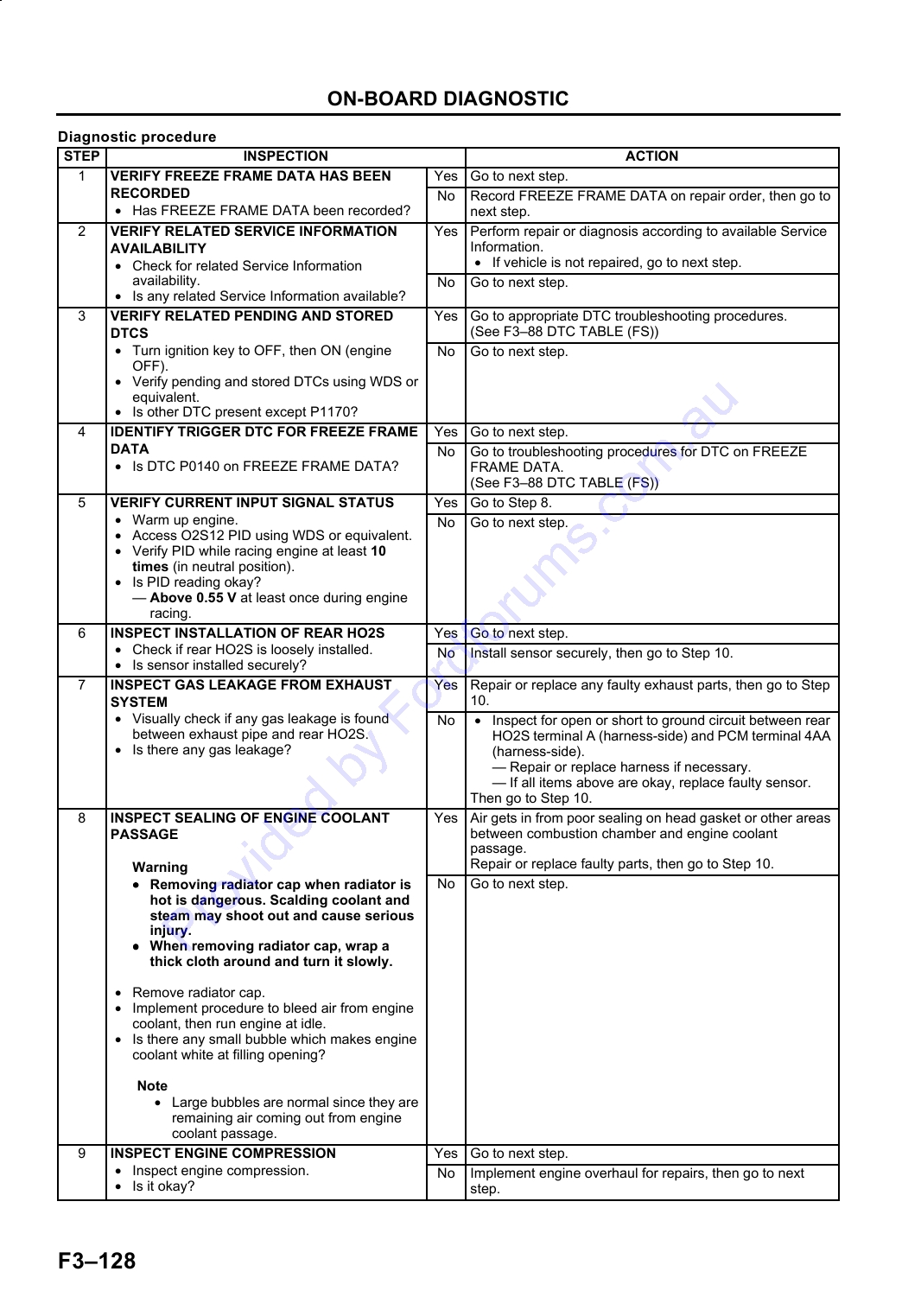

DTC P0140 (FS) ............................................ F3-127

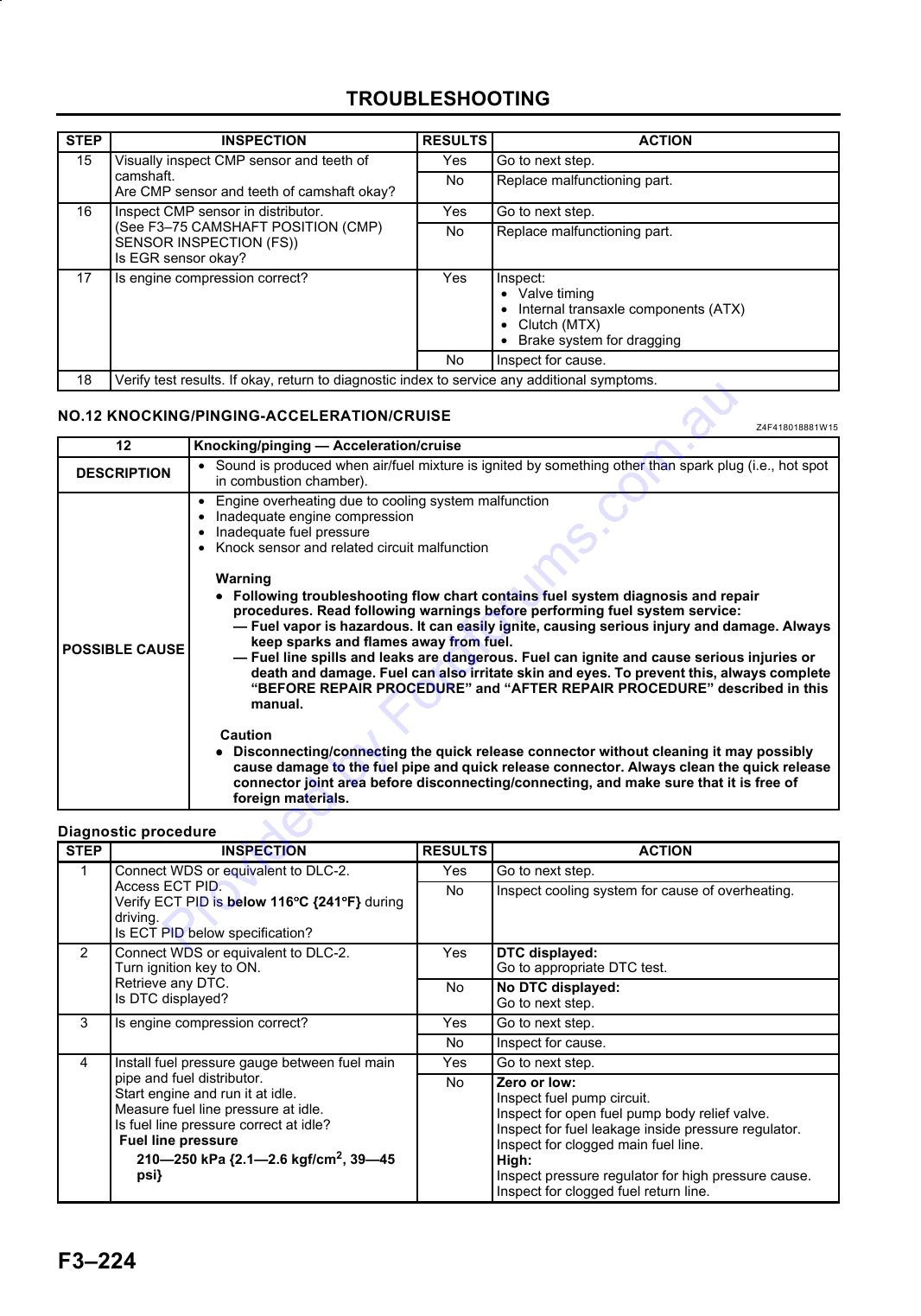

NO.12 KNOCKING/PINGING-

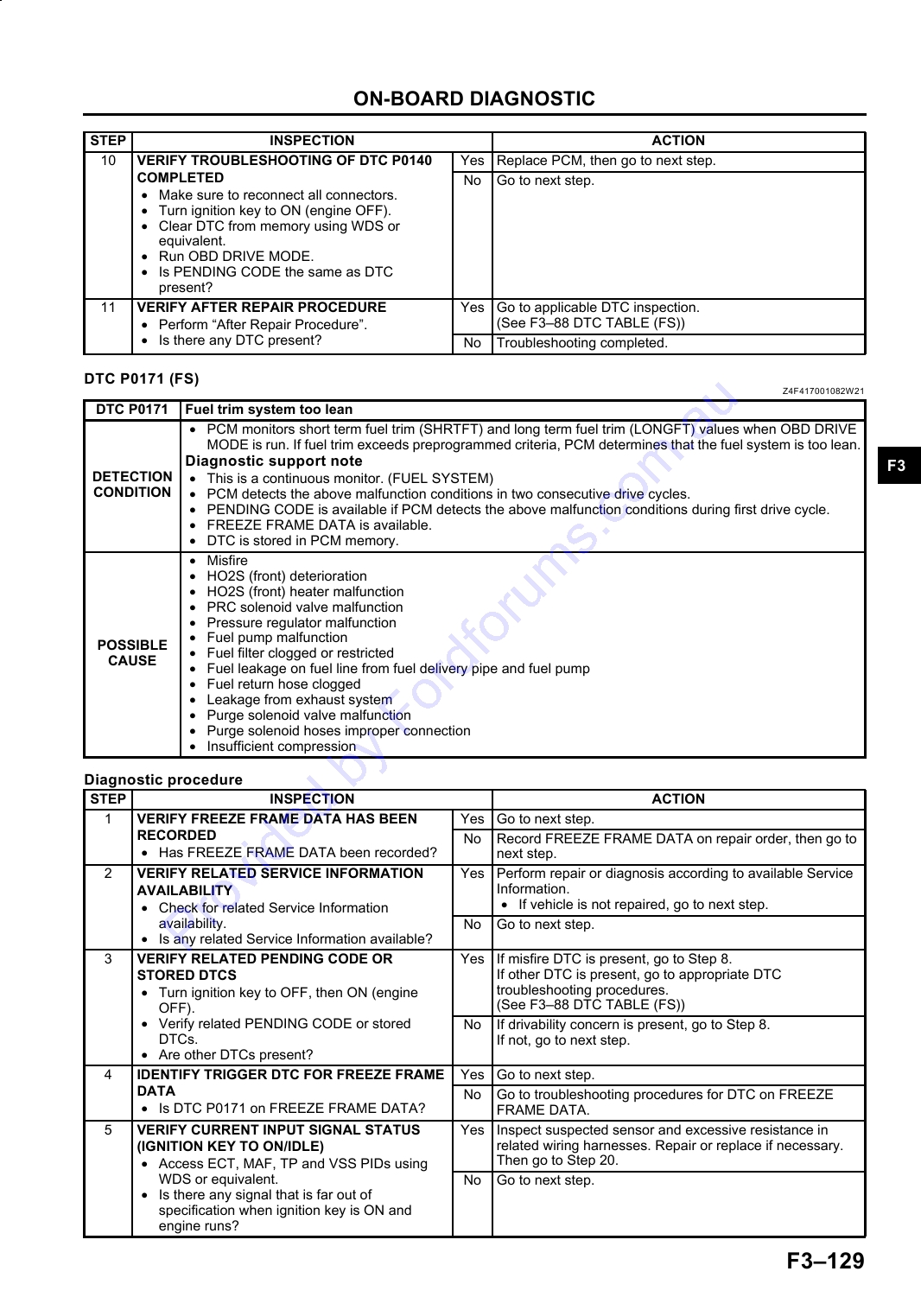

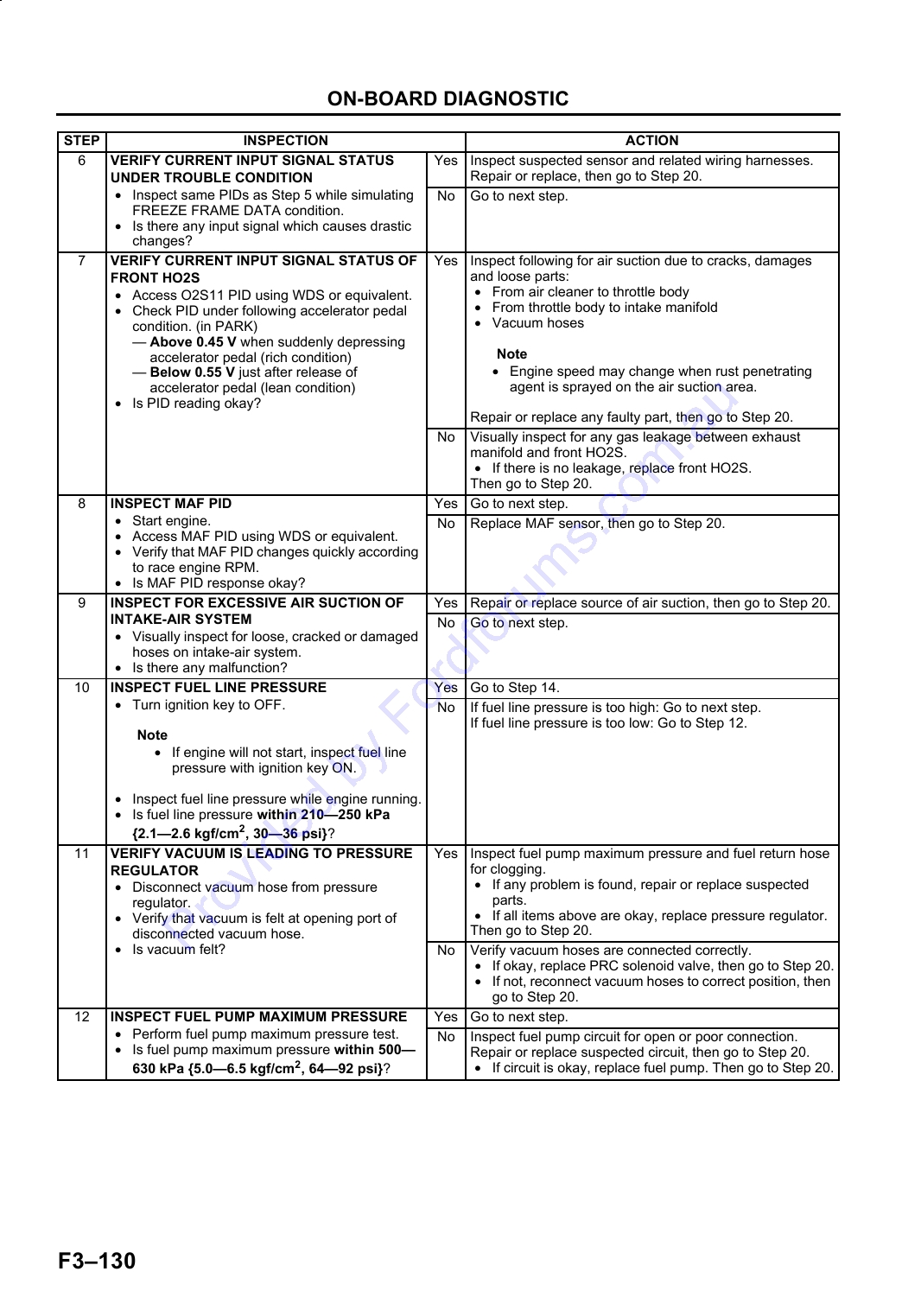

DTC P0171 (FS) ............................................ F3-129

ACCELERATION/CRUISE.......................... F3-224

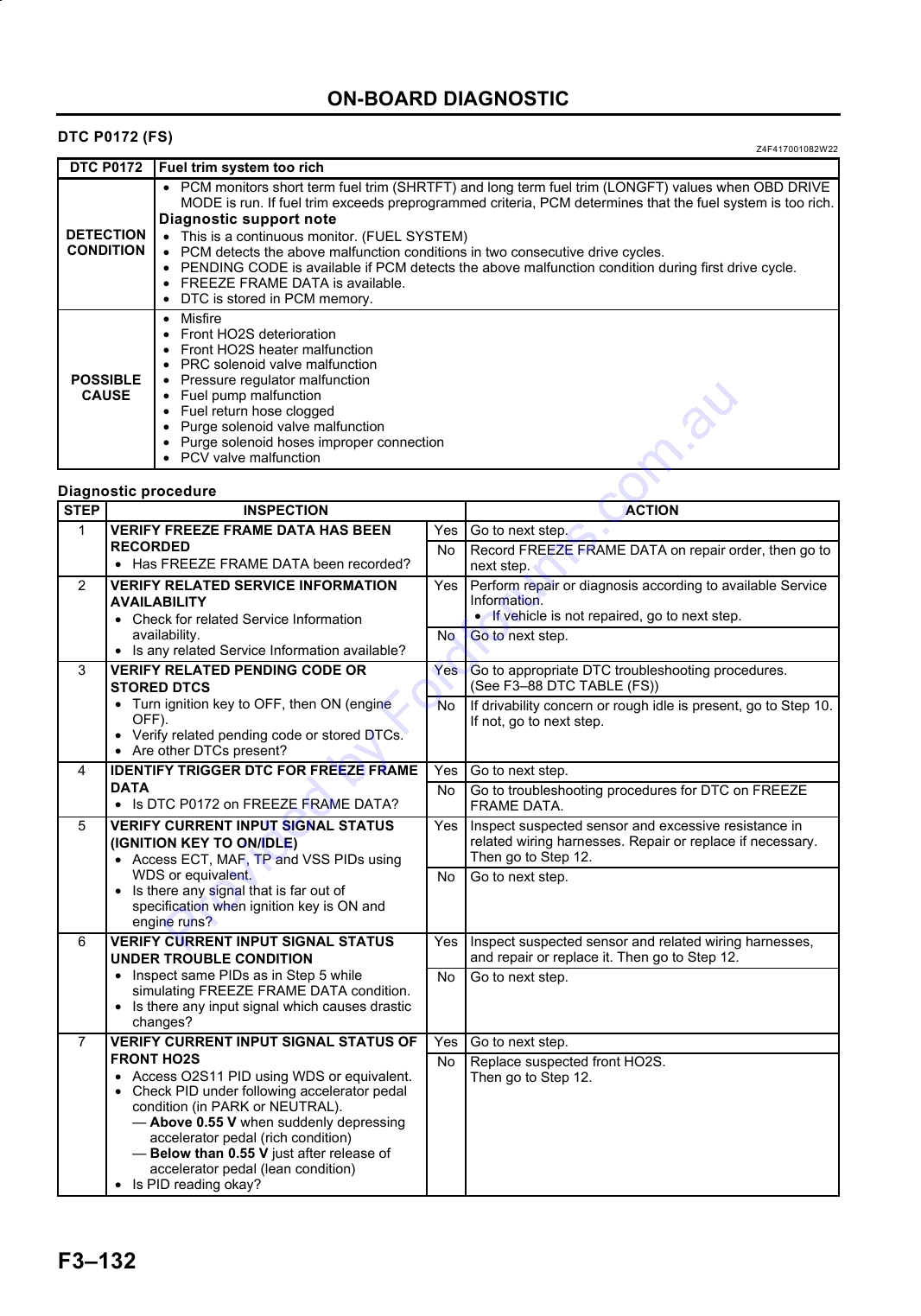

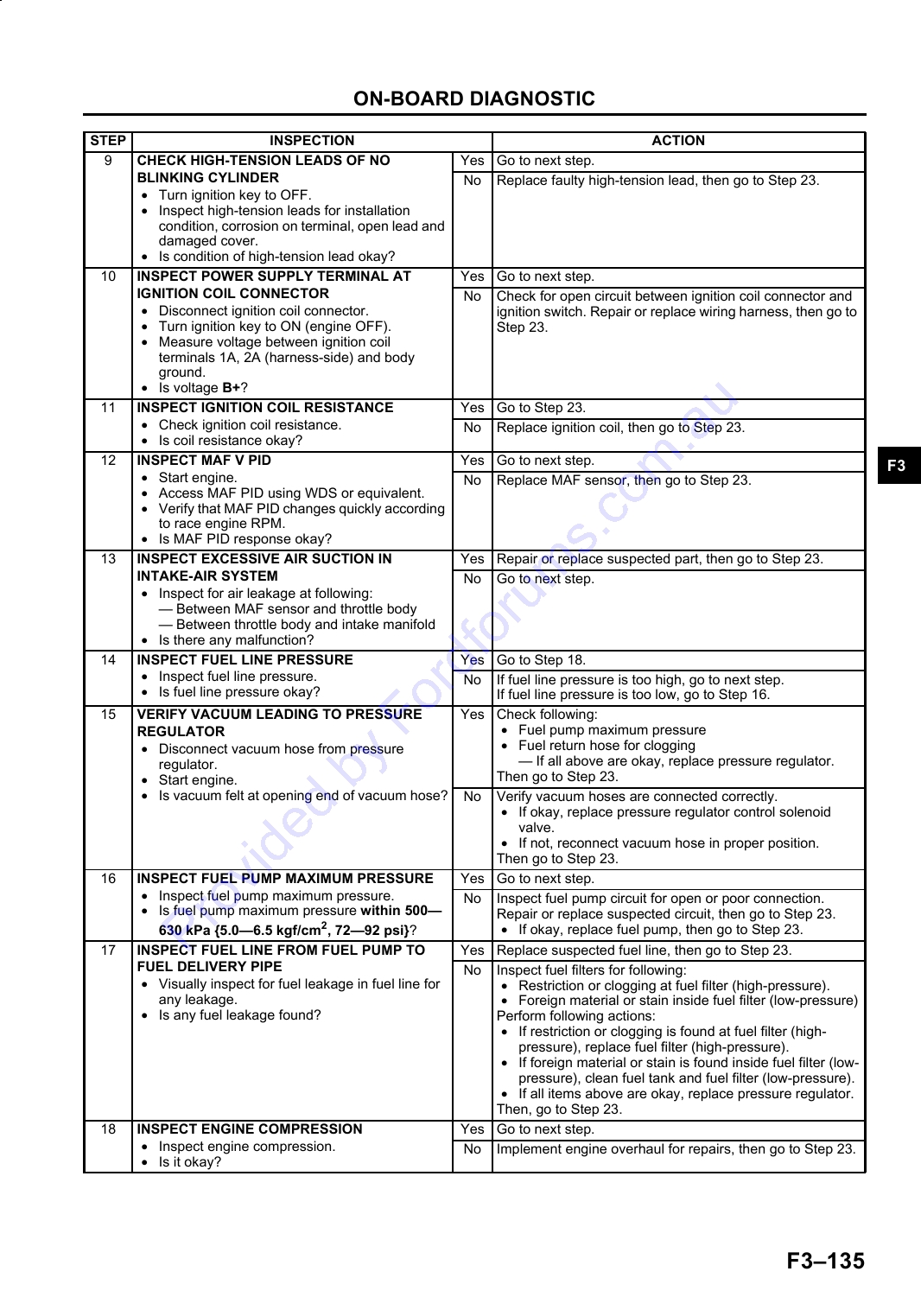

DTC P0172 (FS) ............................................ F3-132

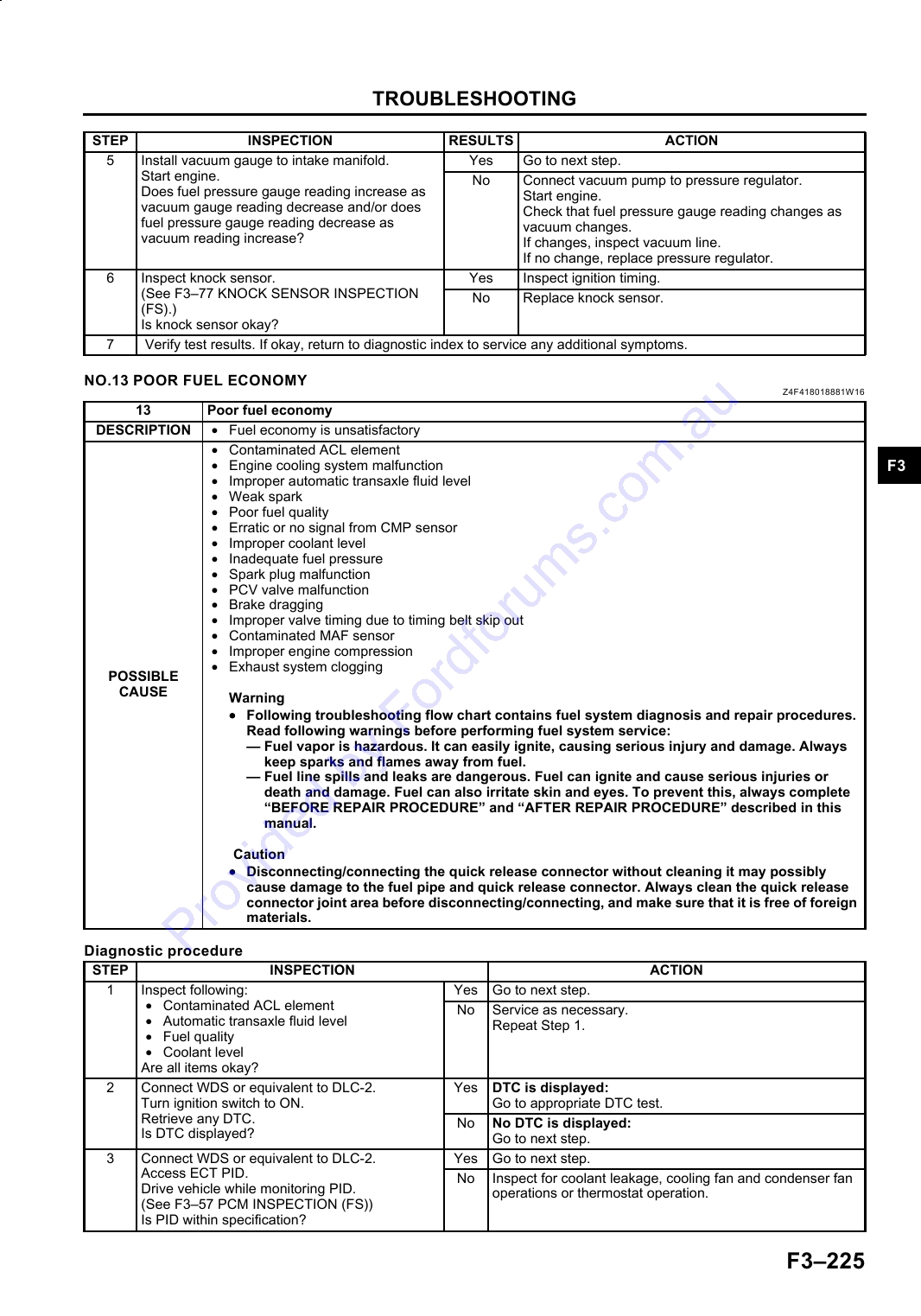

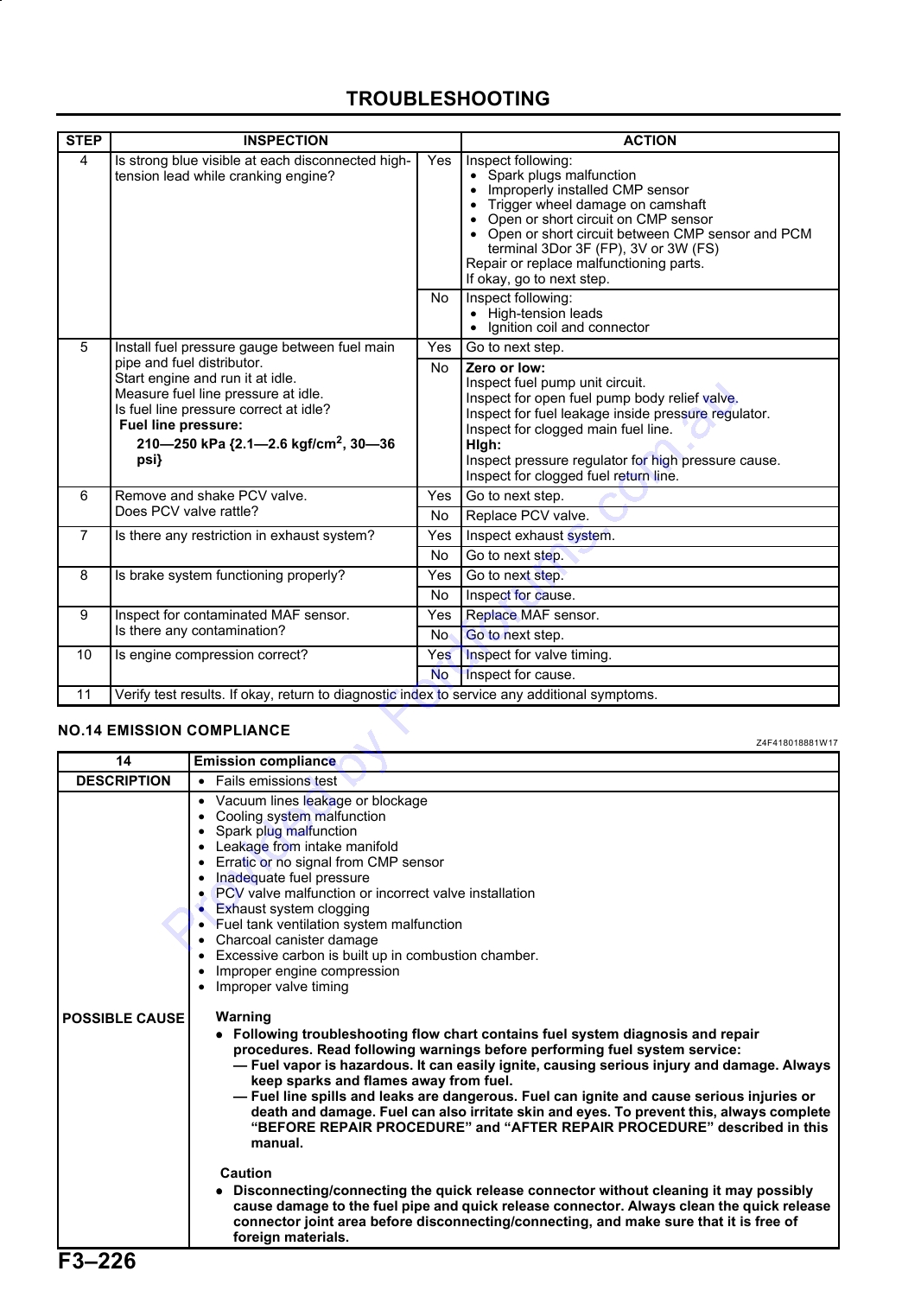

NO.13 POOR FUEL ECONOMY.................... F3-225

DTC P0300 (FS) ............................................ F3-133

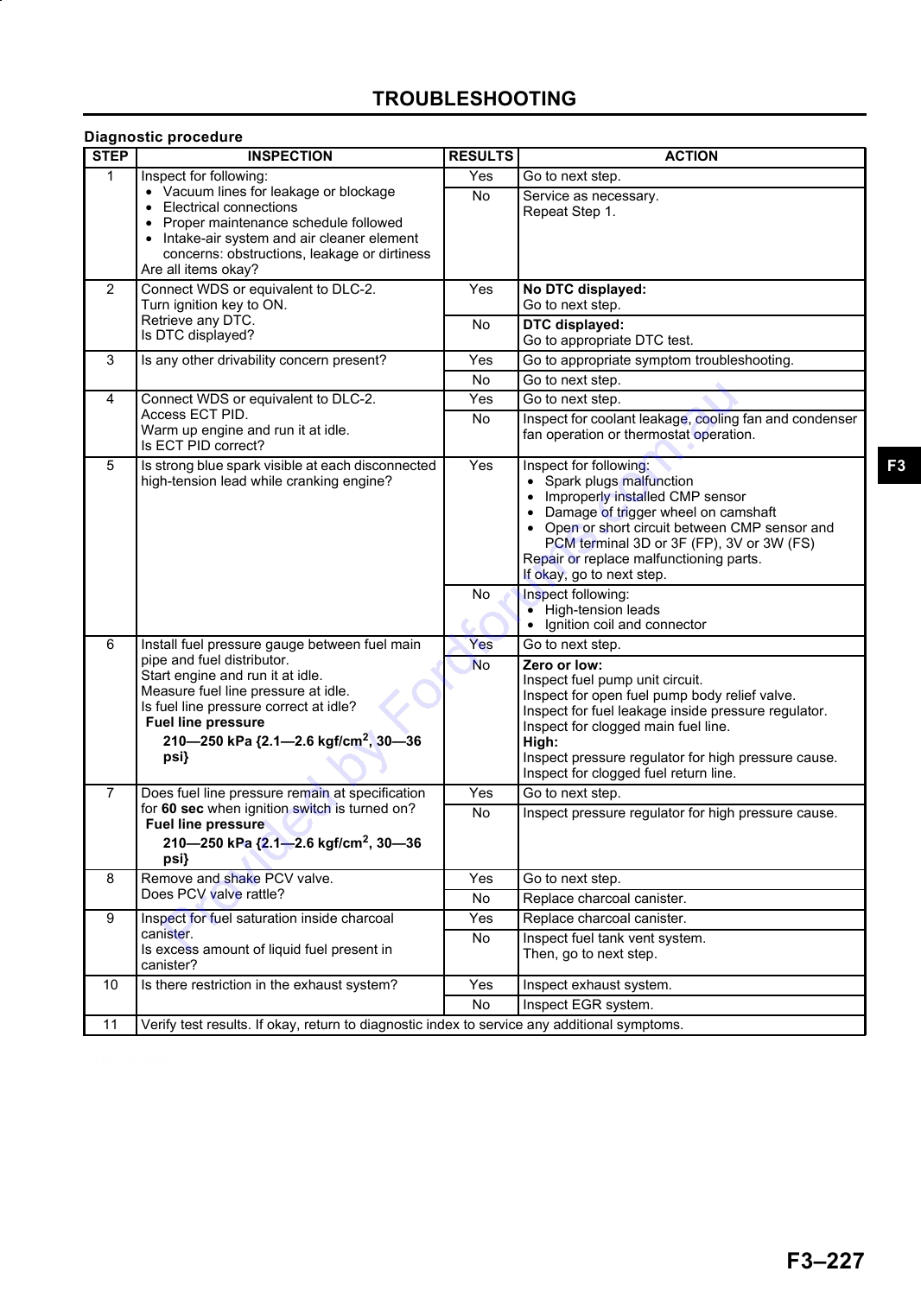

NO.14 EMISSION COMPLIANCE.................. F3-226

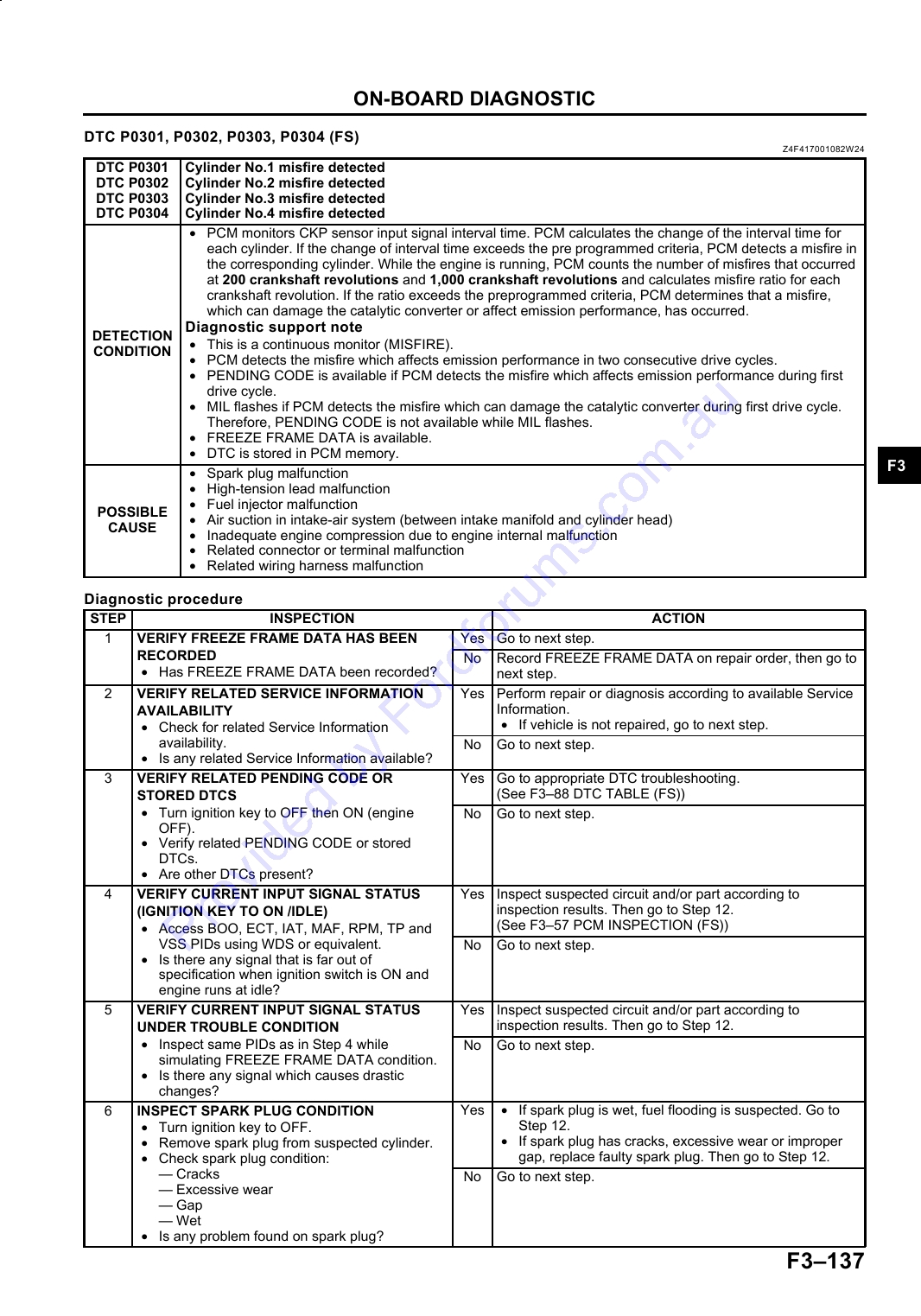

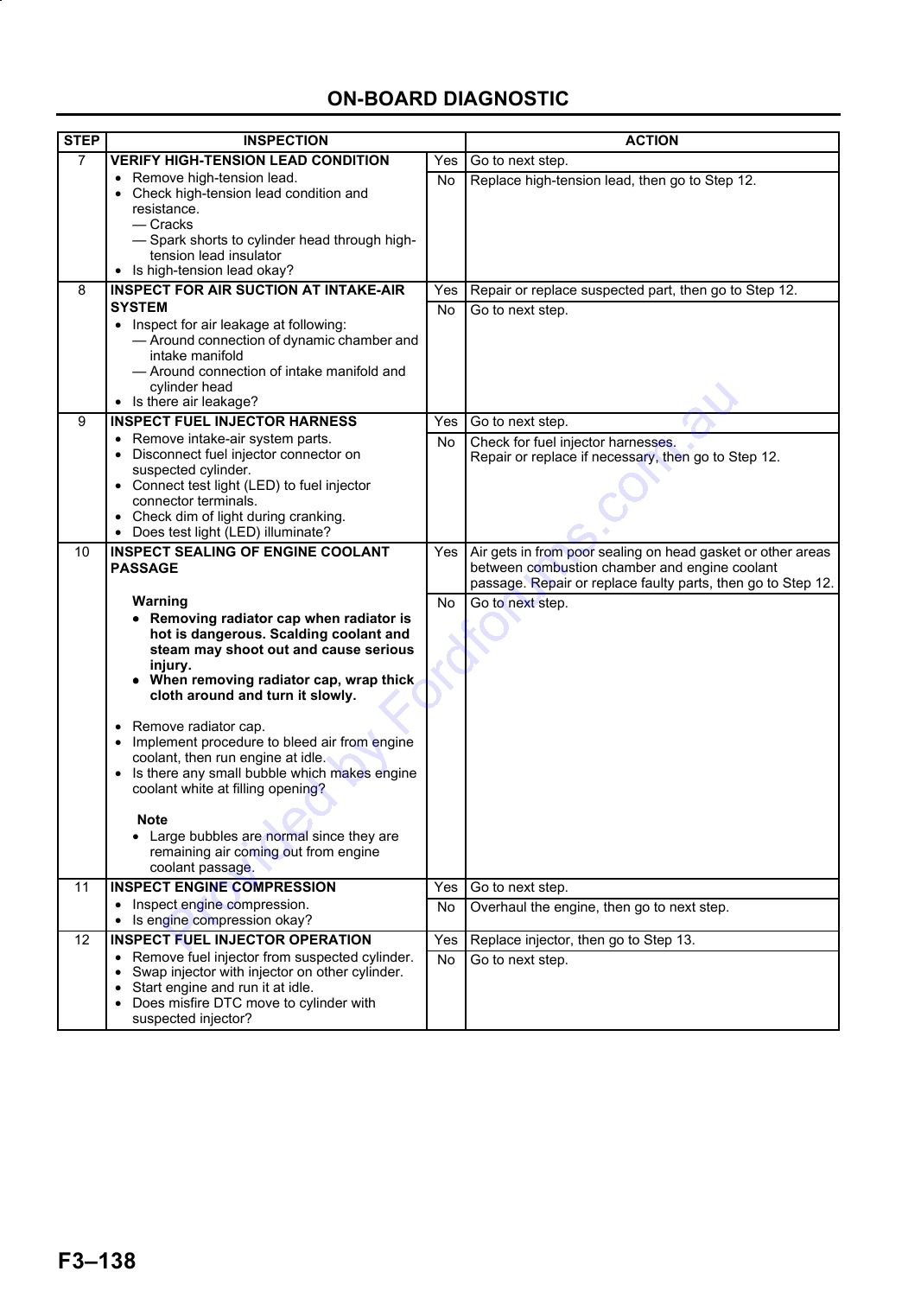

DTC P0301, P0302, P0303, P0304 (FS) ....... F3-137

NO.15 HIGH OIL

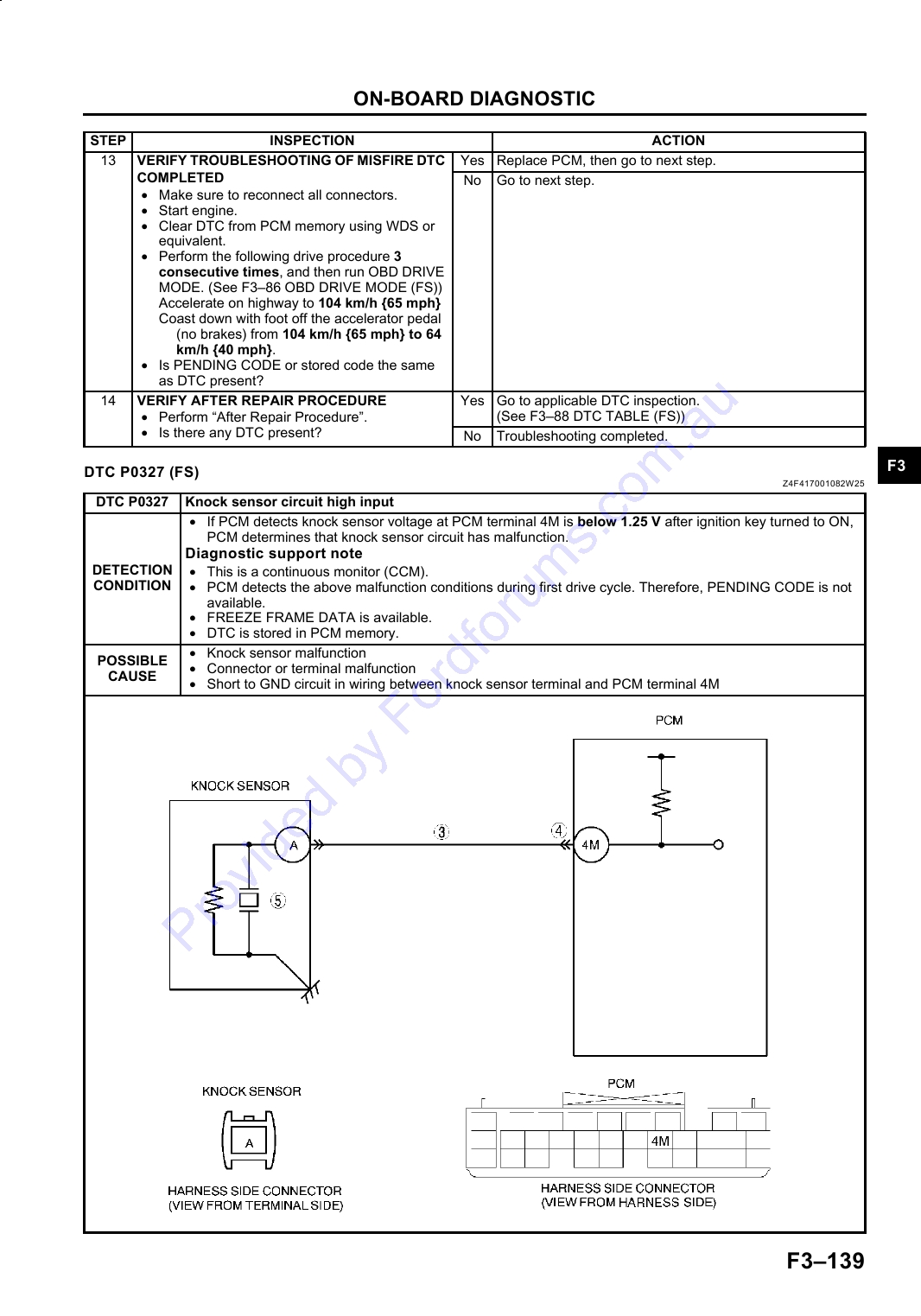

DTC P0327 (FS) ............................................ F3-139

CONSUMPTION/LEAKAGE ....................... F3-228

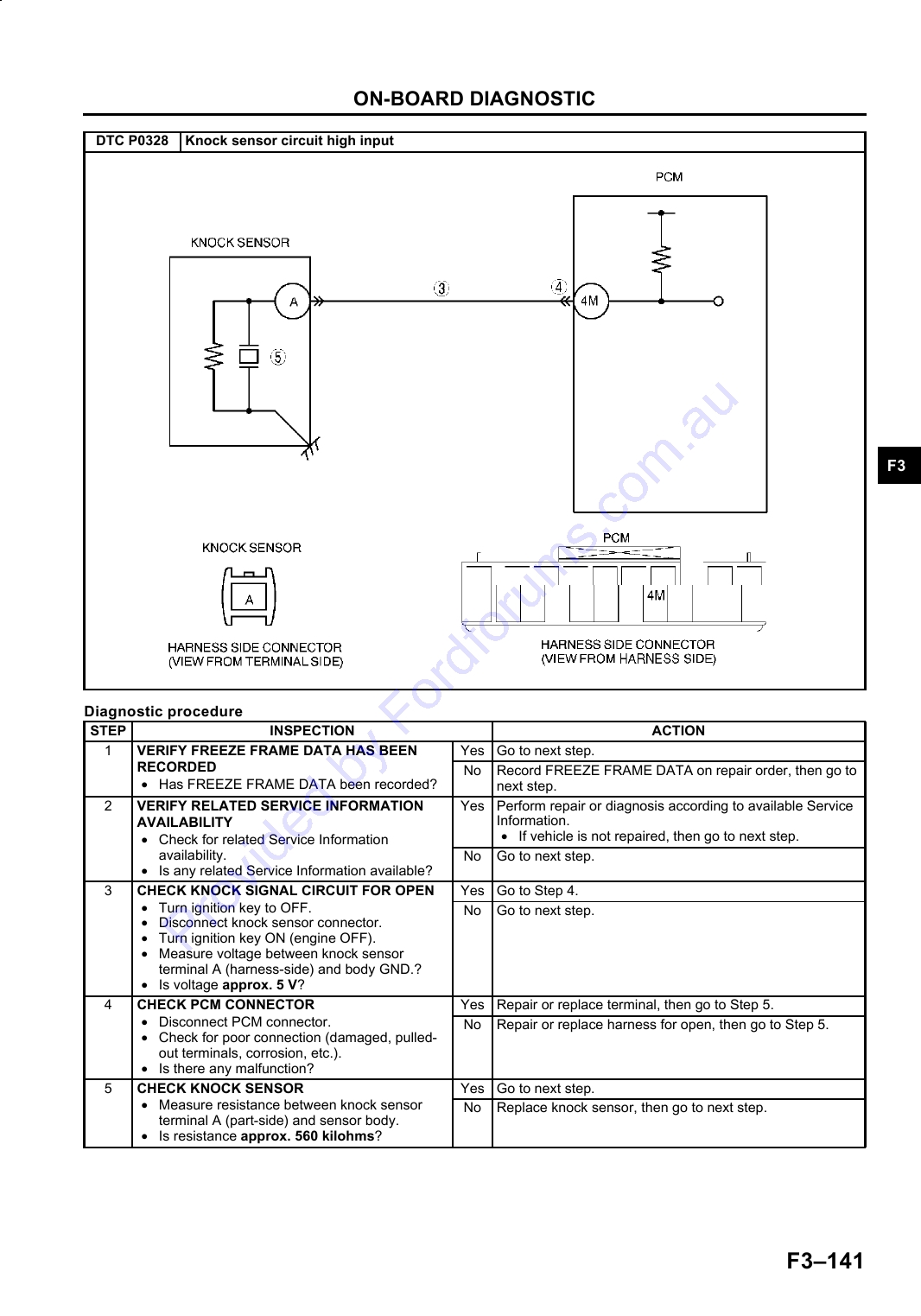

DTC P0328 (FS) ............................................ F3-140

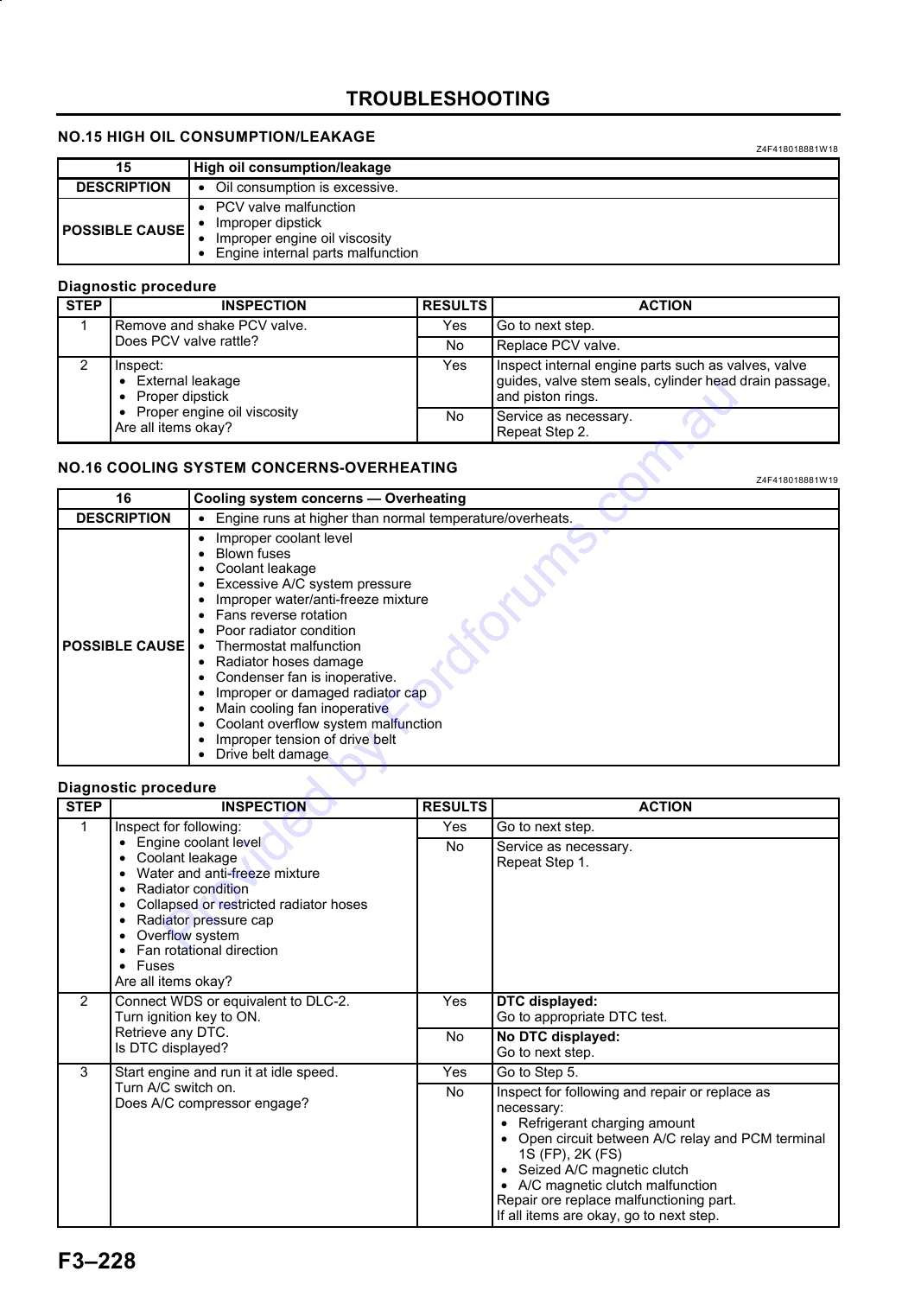

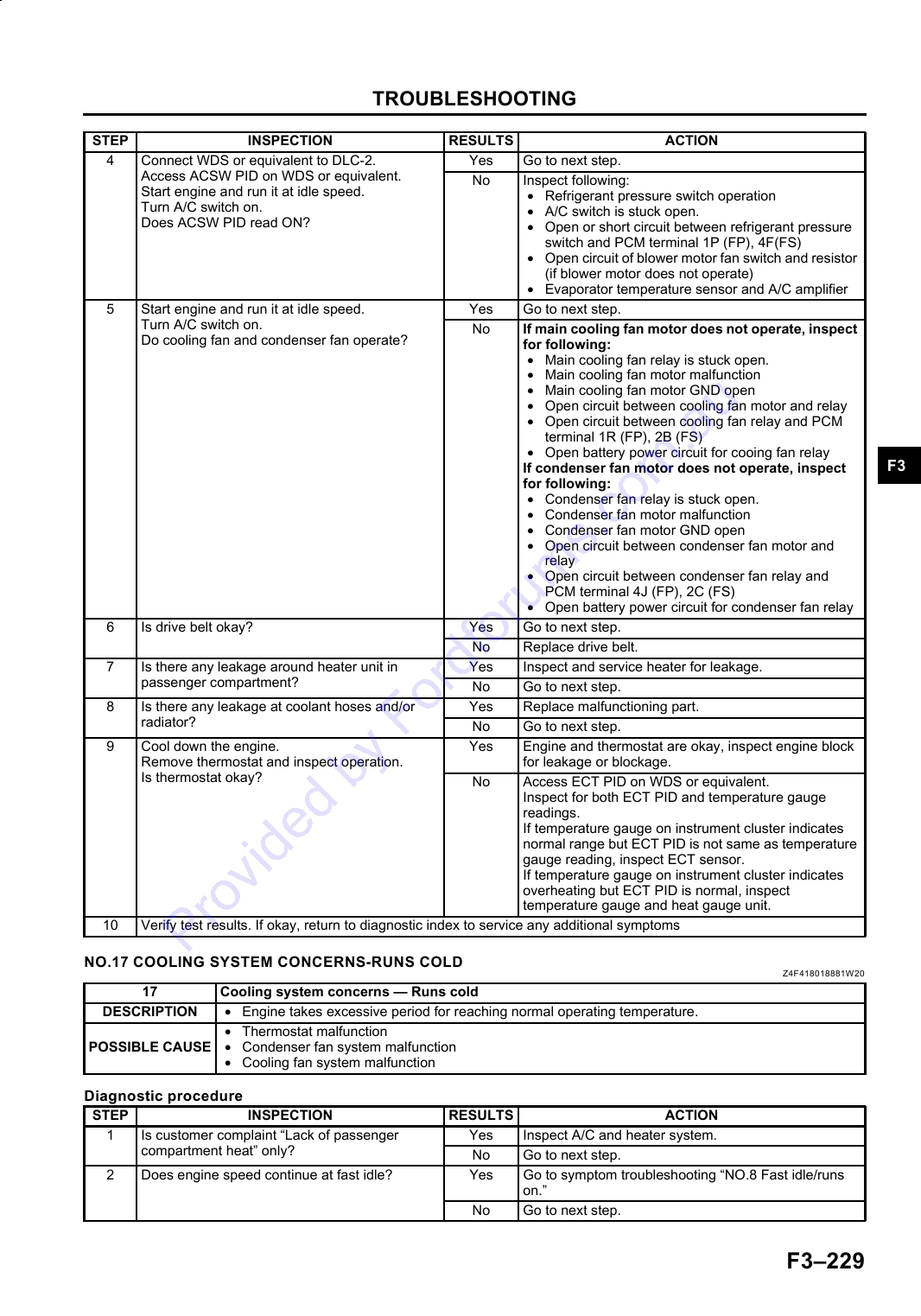

NO.16 COOLING SYSTEM

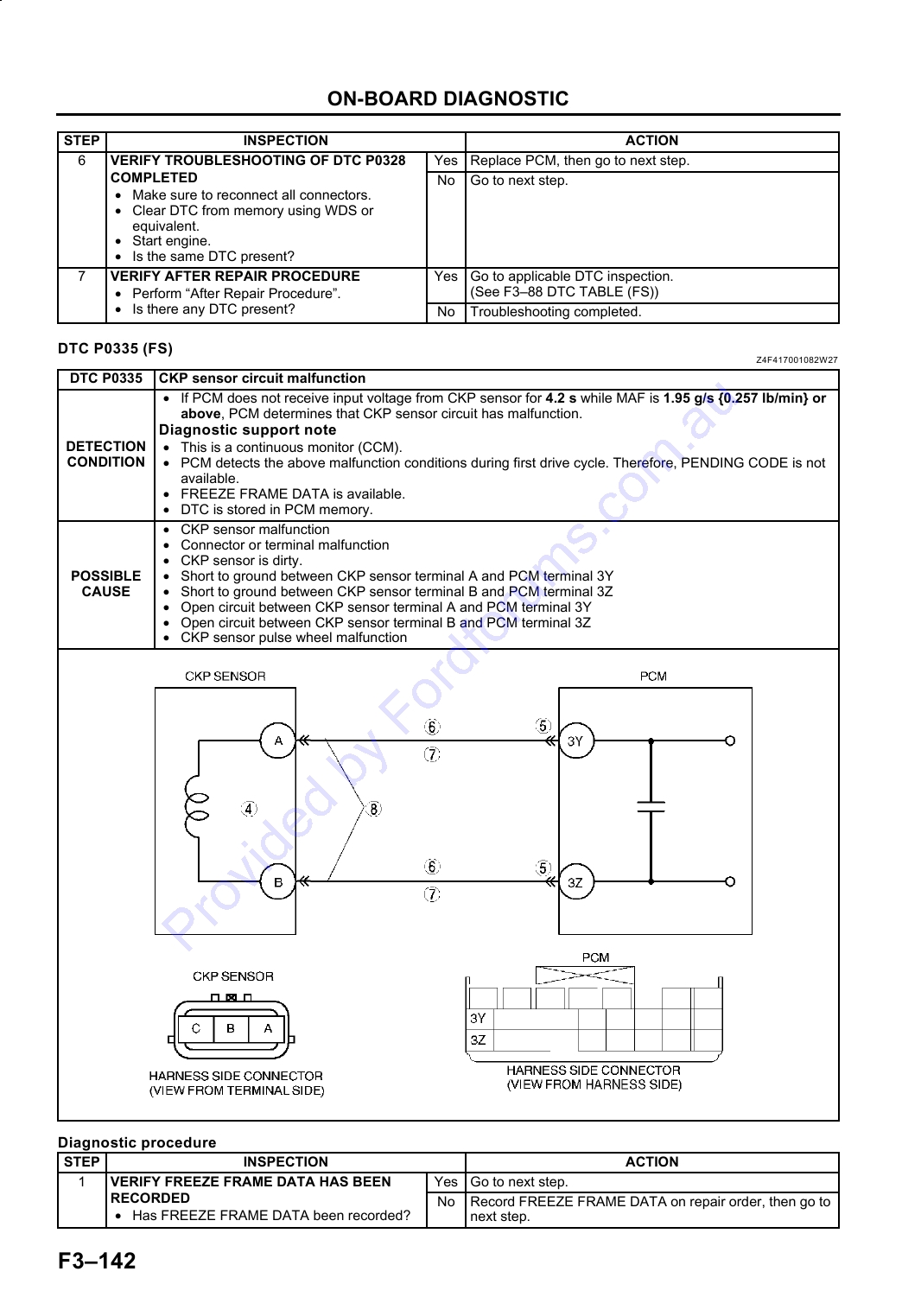

DTC P0335 (FS) ............................................ F3-142

CONCERNS-OVERHEATING .................... F3-228

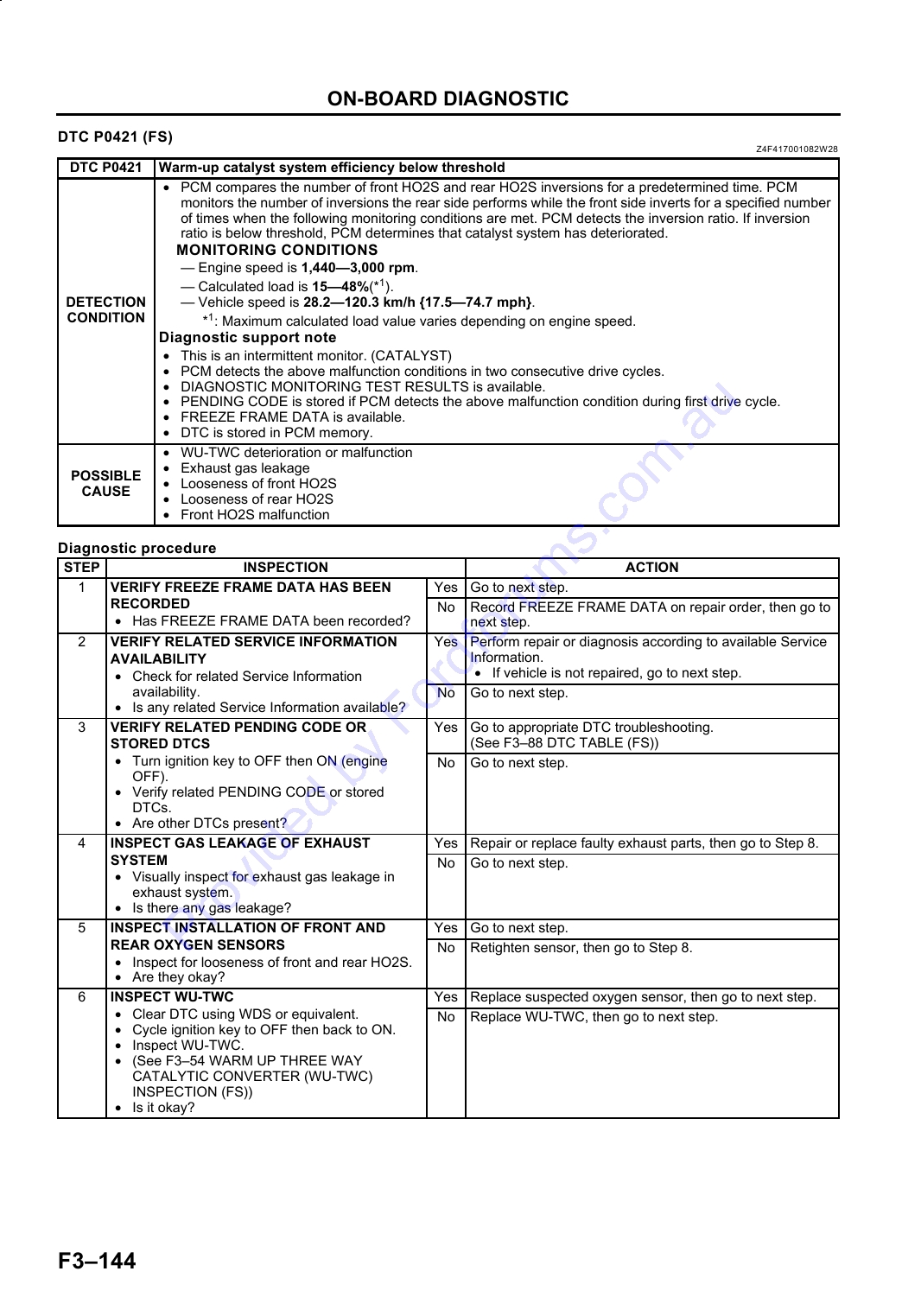

DTC P0421 (FS) ............................................ F3-144

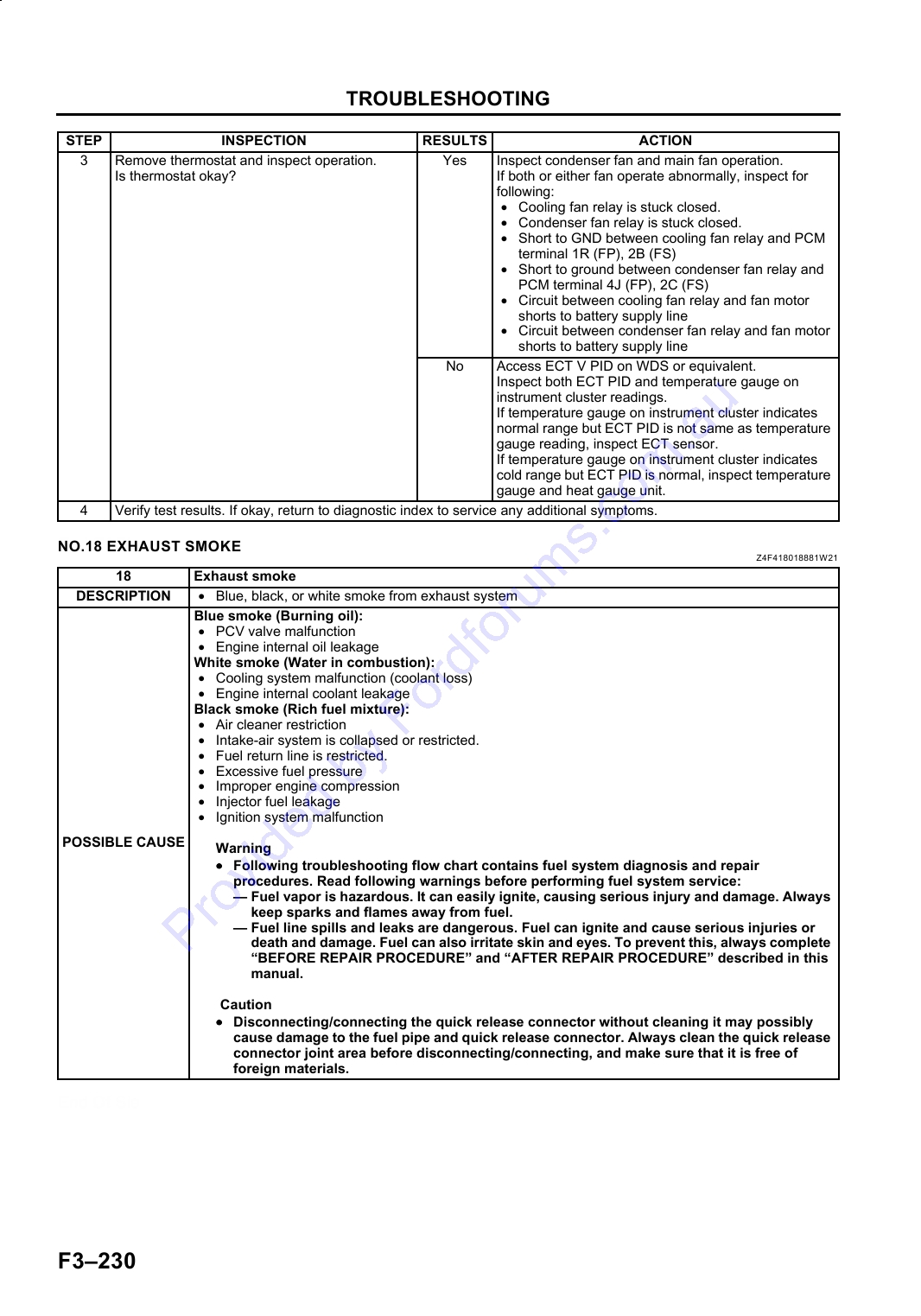

NO.17 COOLING SYSTEM

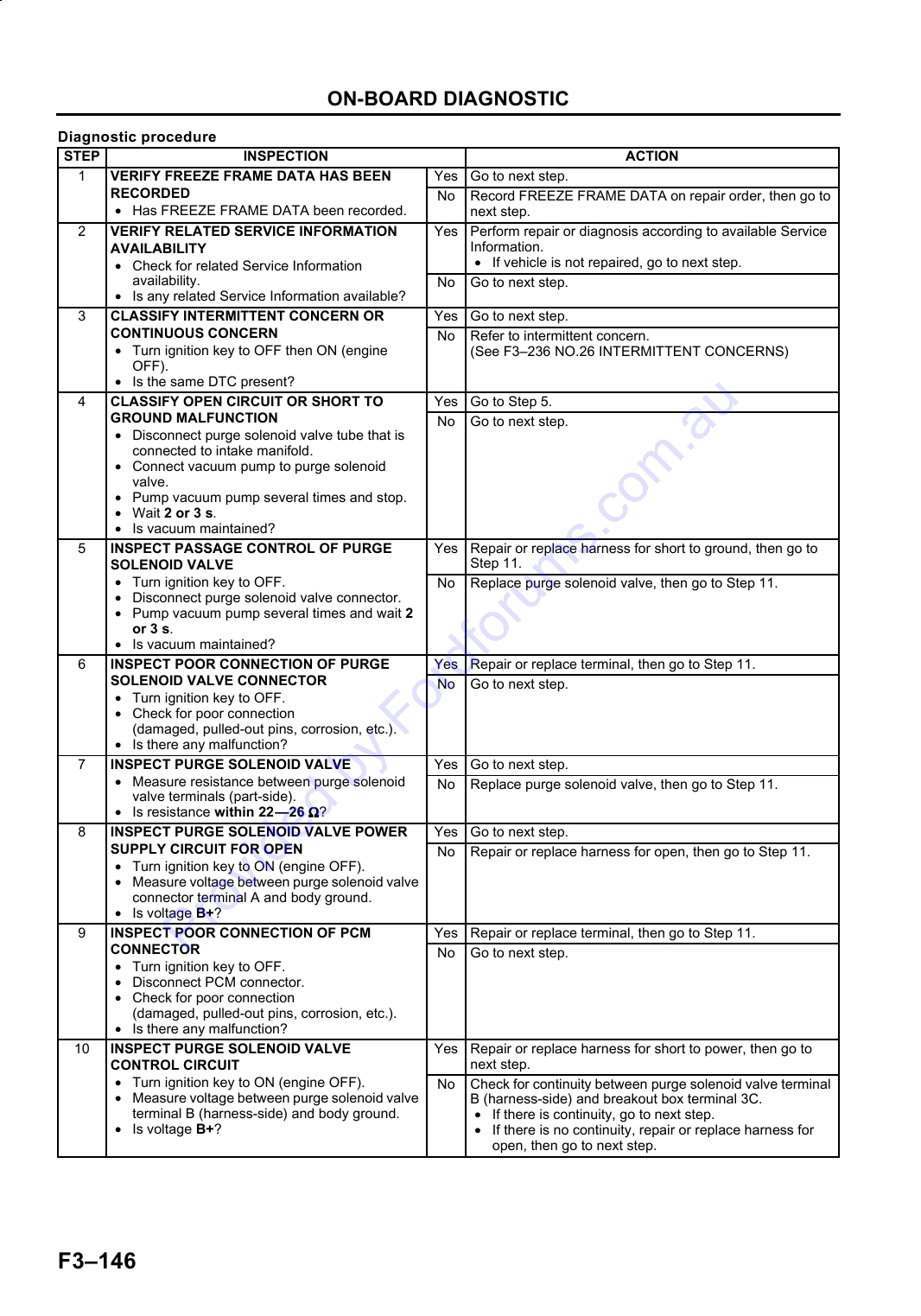

DTC P0443 (FS) ............................................ F3-145

CONCERNS-RUNS COLD ......................... F3-229

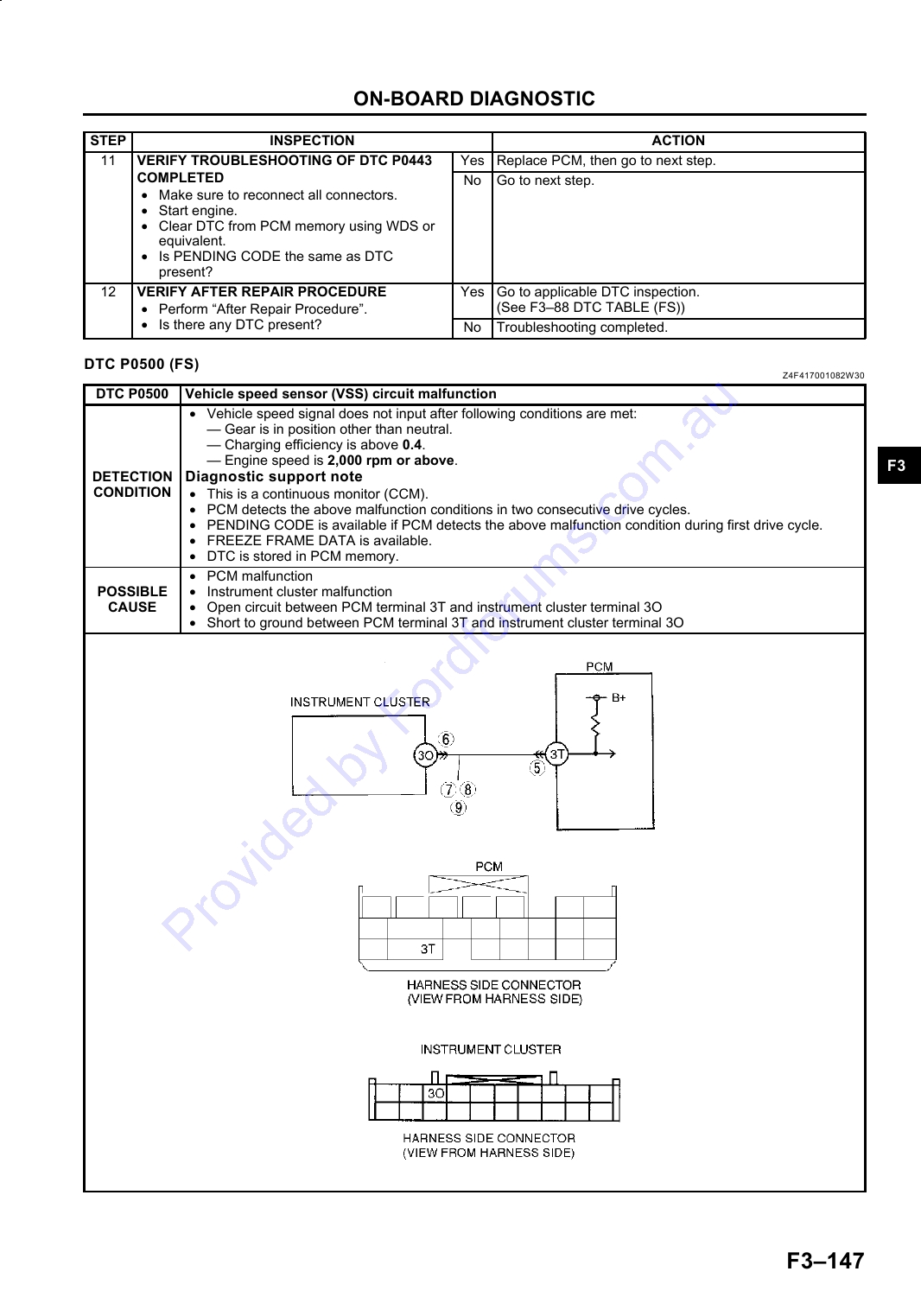

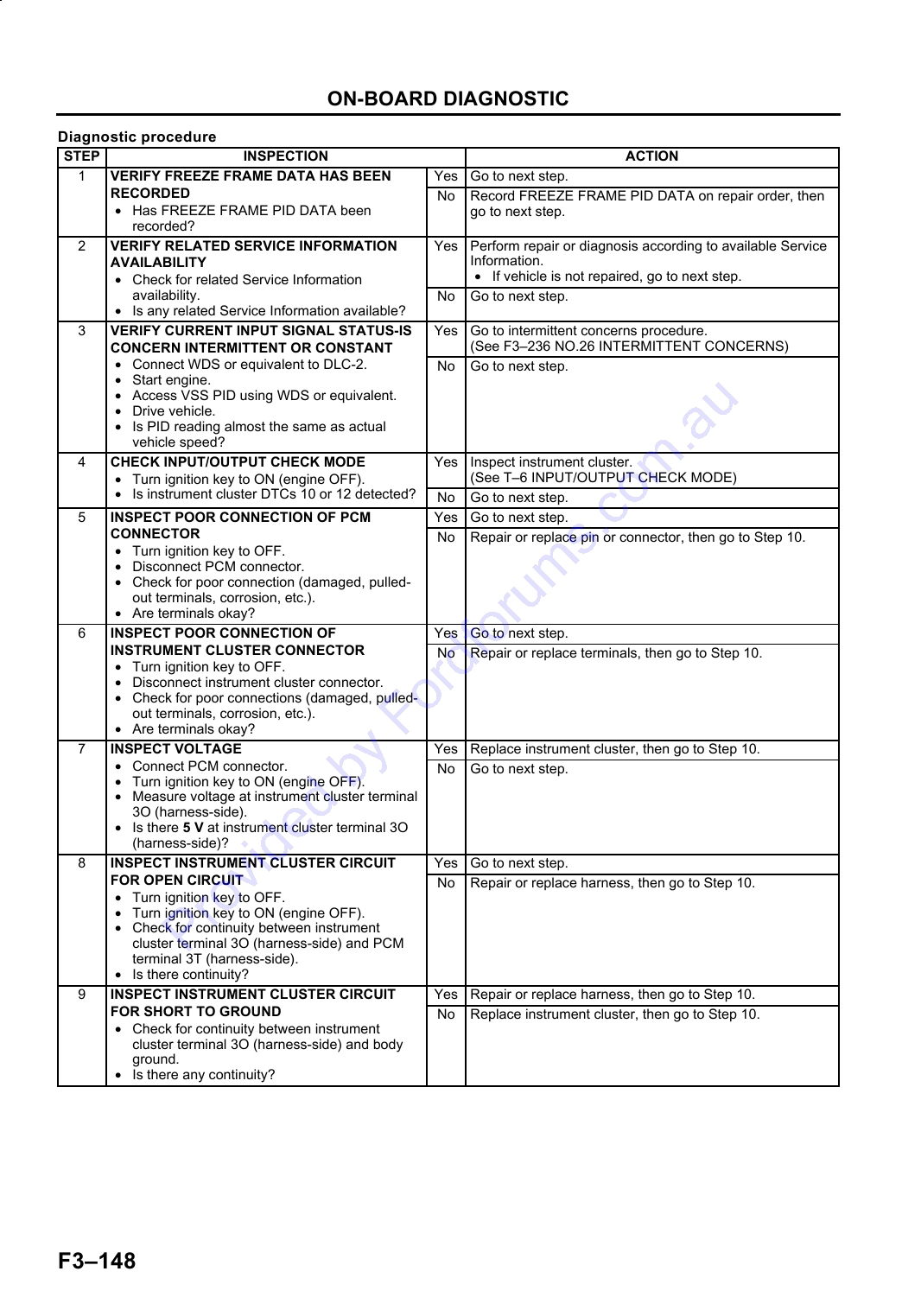

DTC P0500 (FS) ............................................ F3-147

NO.18 EXHAUST SMOKE ............................. F3-230

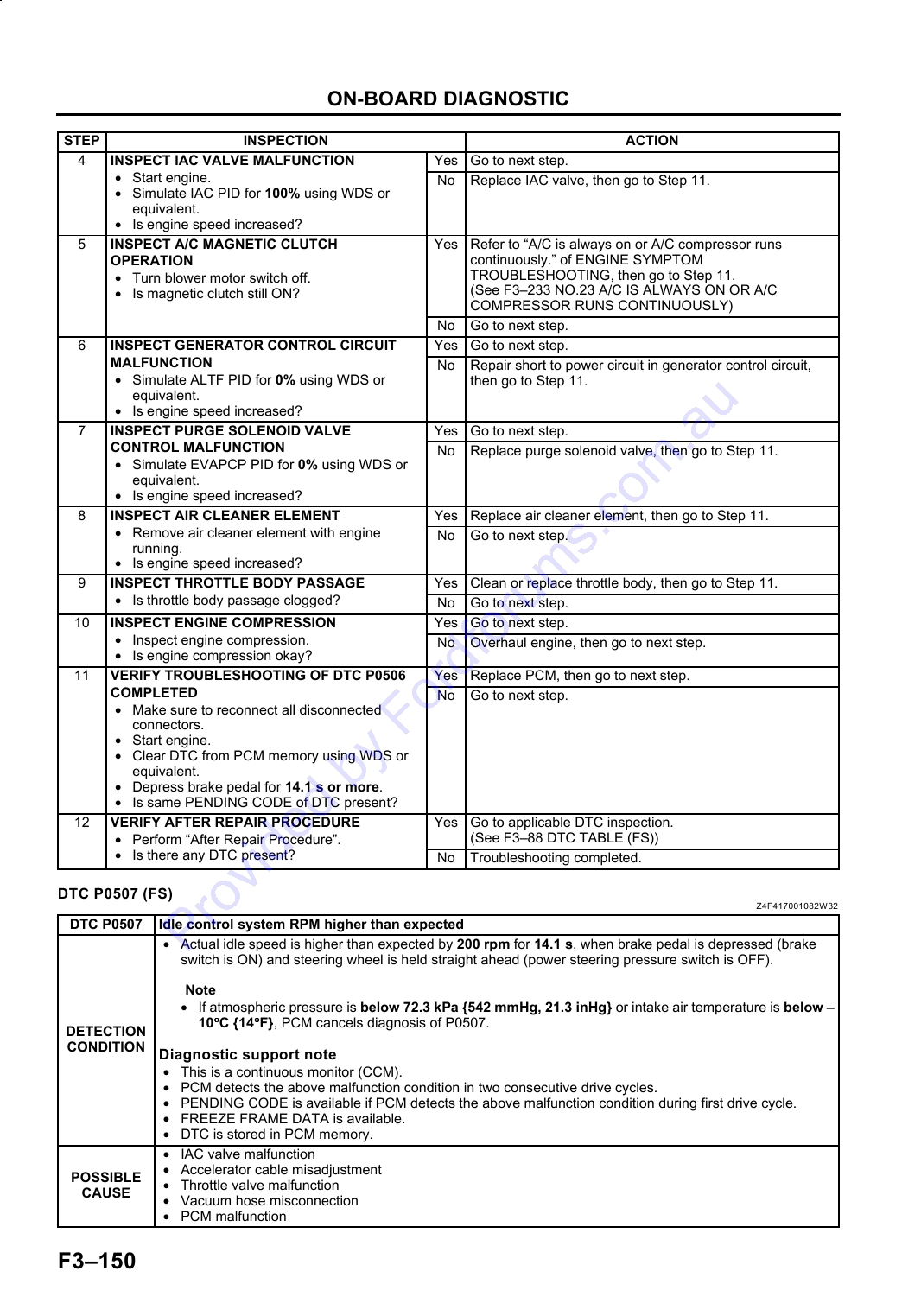

DTC P0506 (FS) ............................................ F3-149

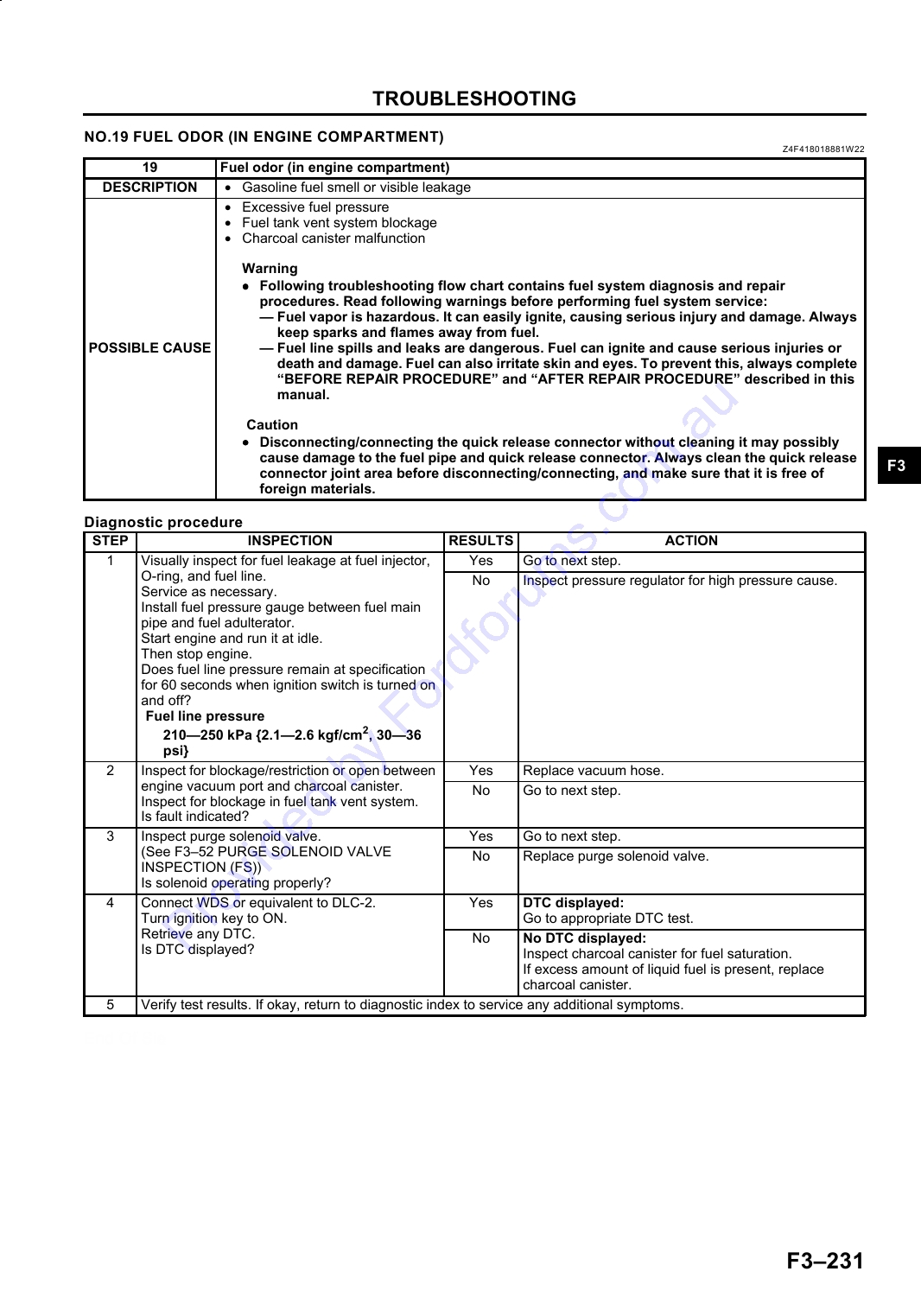

NO.19 FUEL ODOR (IN ENGINE

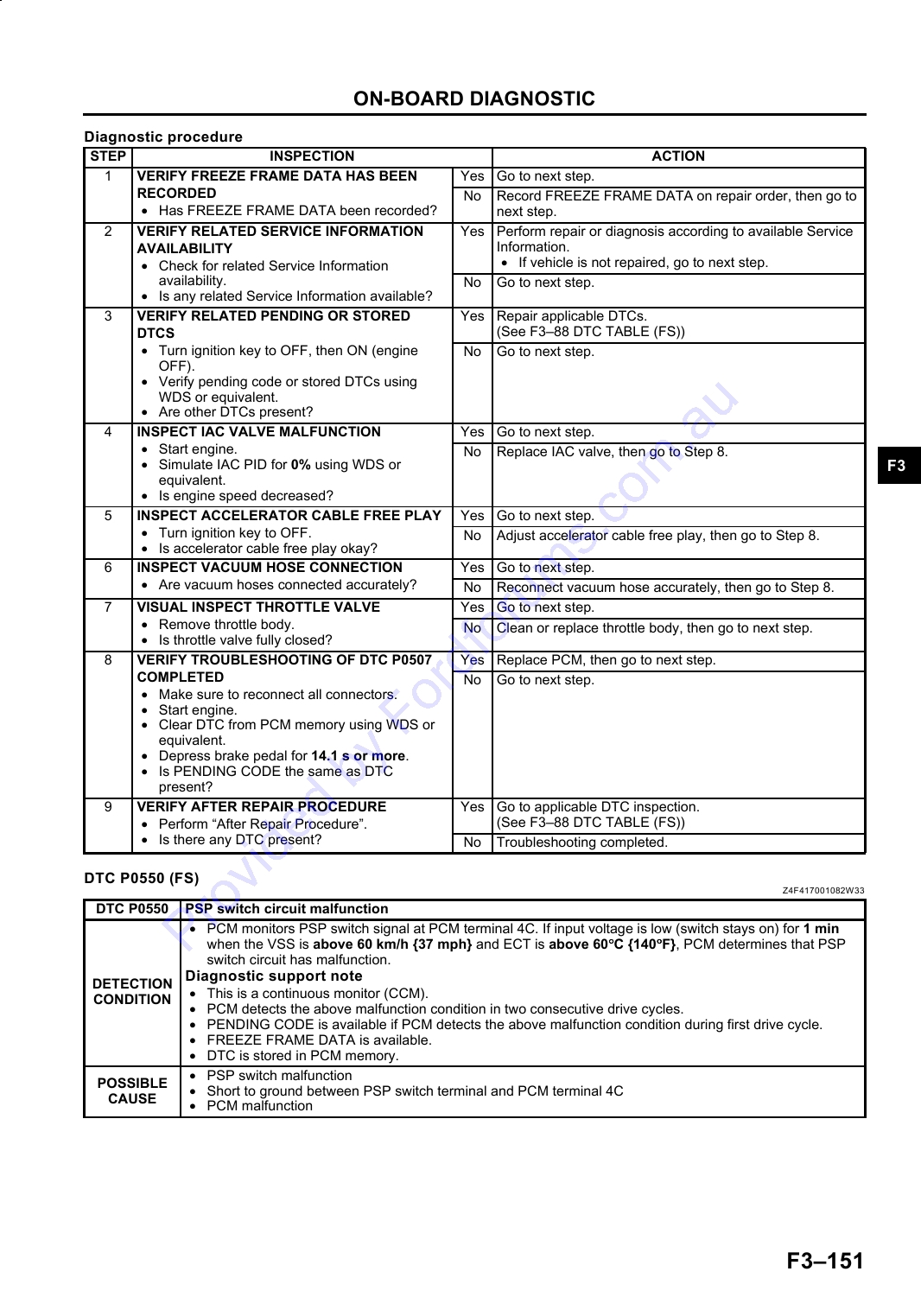

DTC P0507 (FS) ............................................ F3-150

COMPARTMENT) ....................................... F3-231

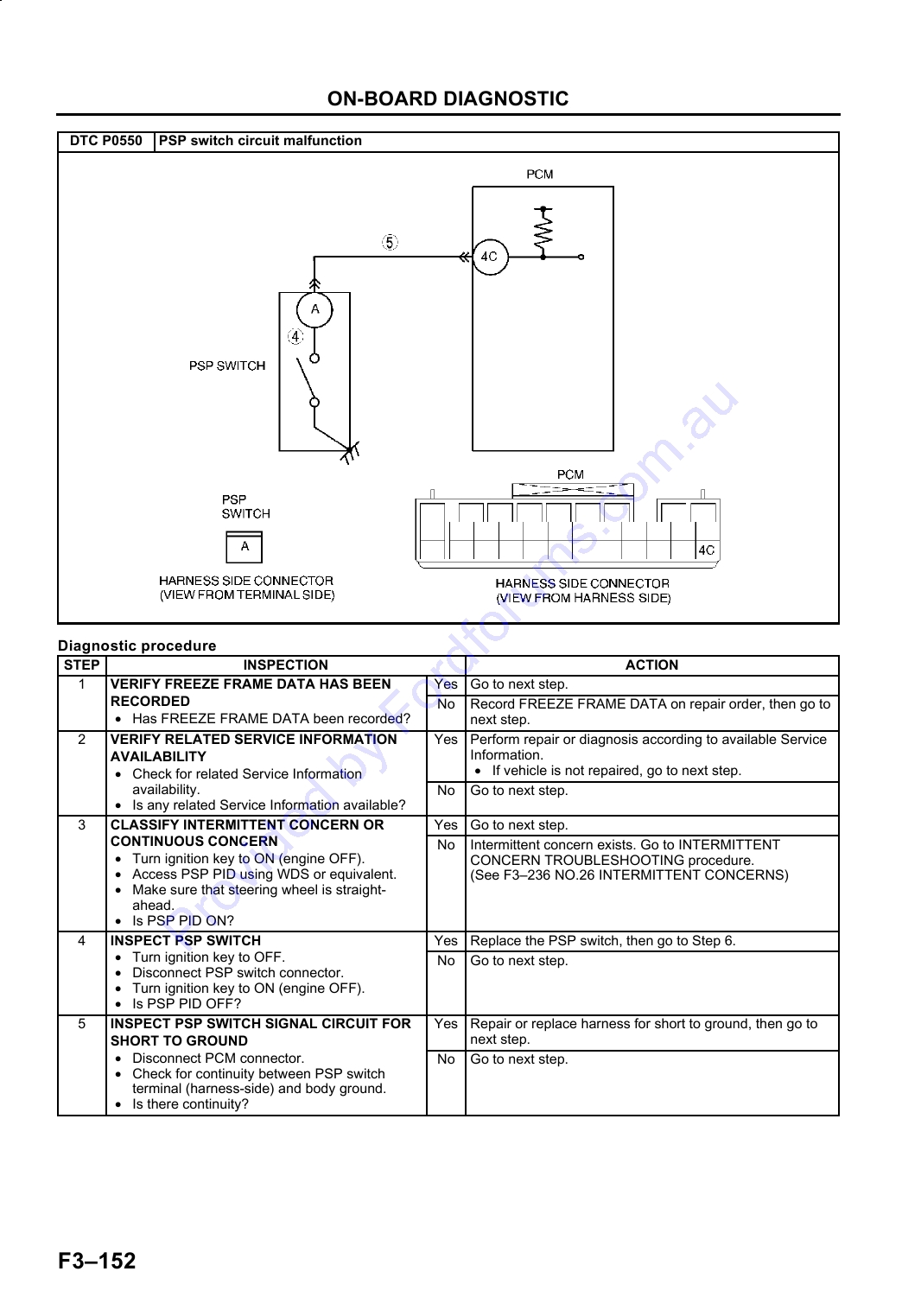

DTC P0550 (FS) ............................................ F3-151

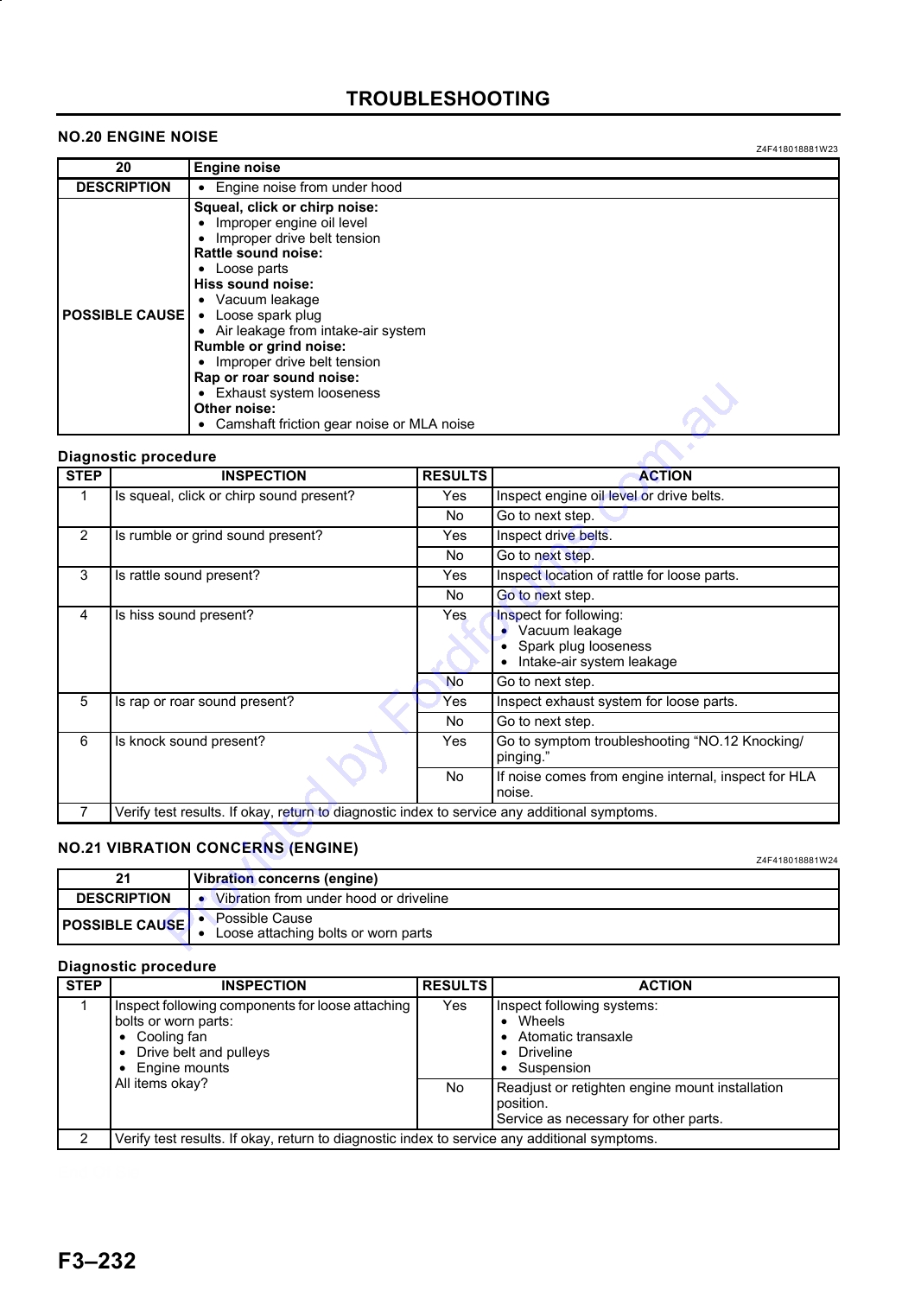

NO.20 ENGINE NOISE .................................. F3-232

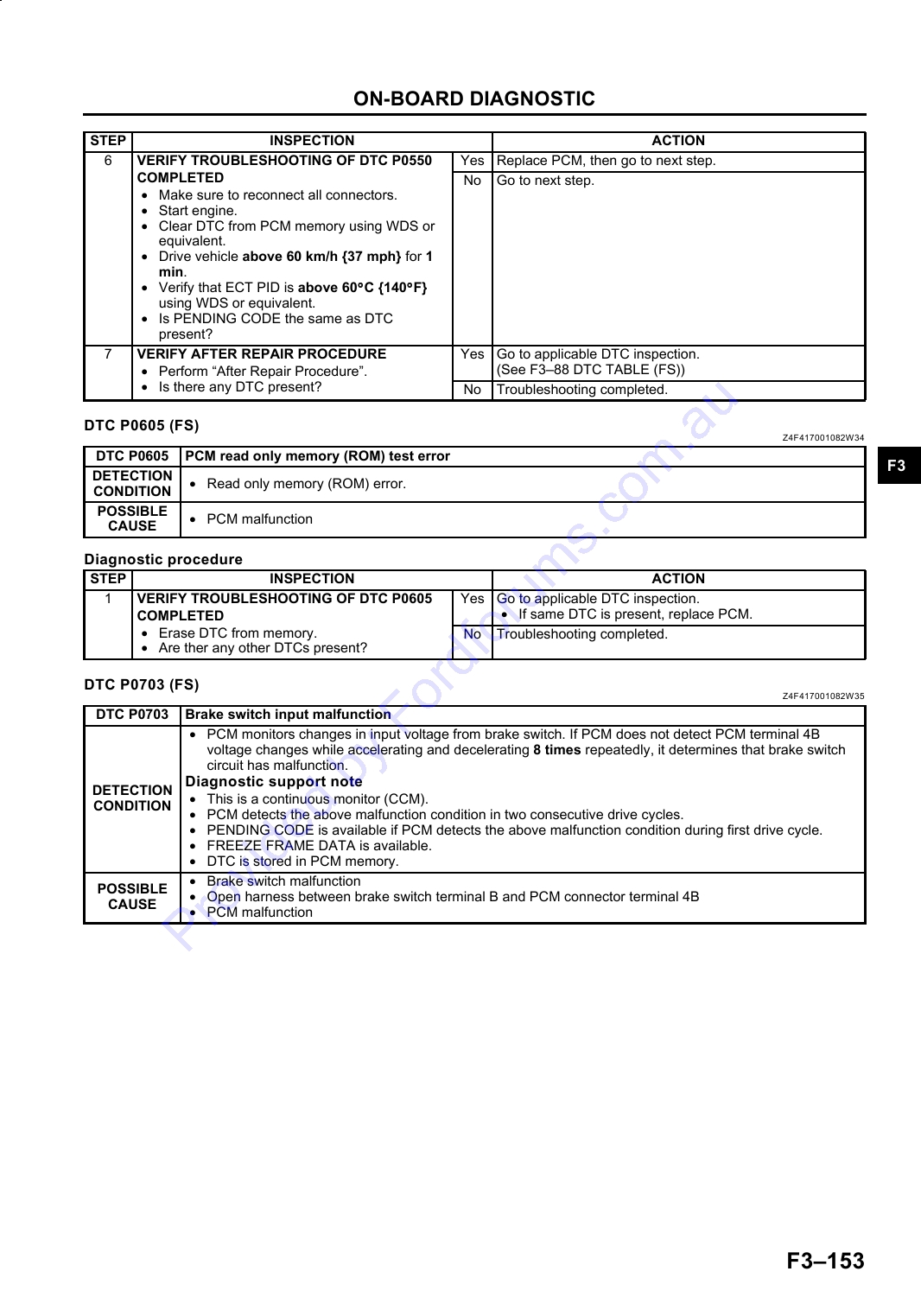

DTC P0605 (FS) ............................................ F3-153

NO.21 VIBRATION CONCERNS (ENGINE).. F3-232

DTC P0703 (FS) ............................................ F3-153

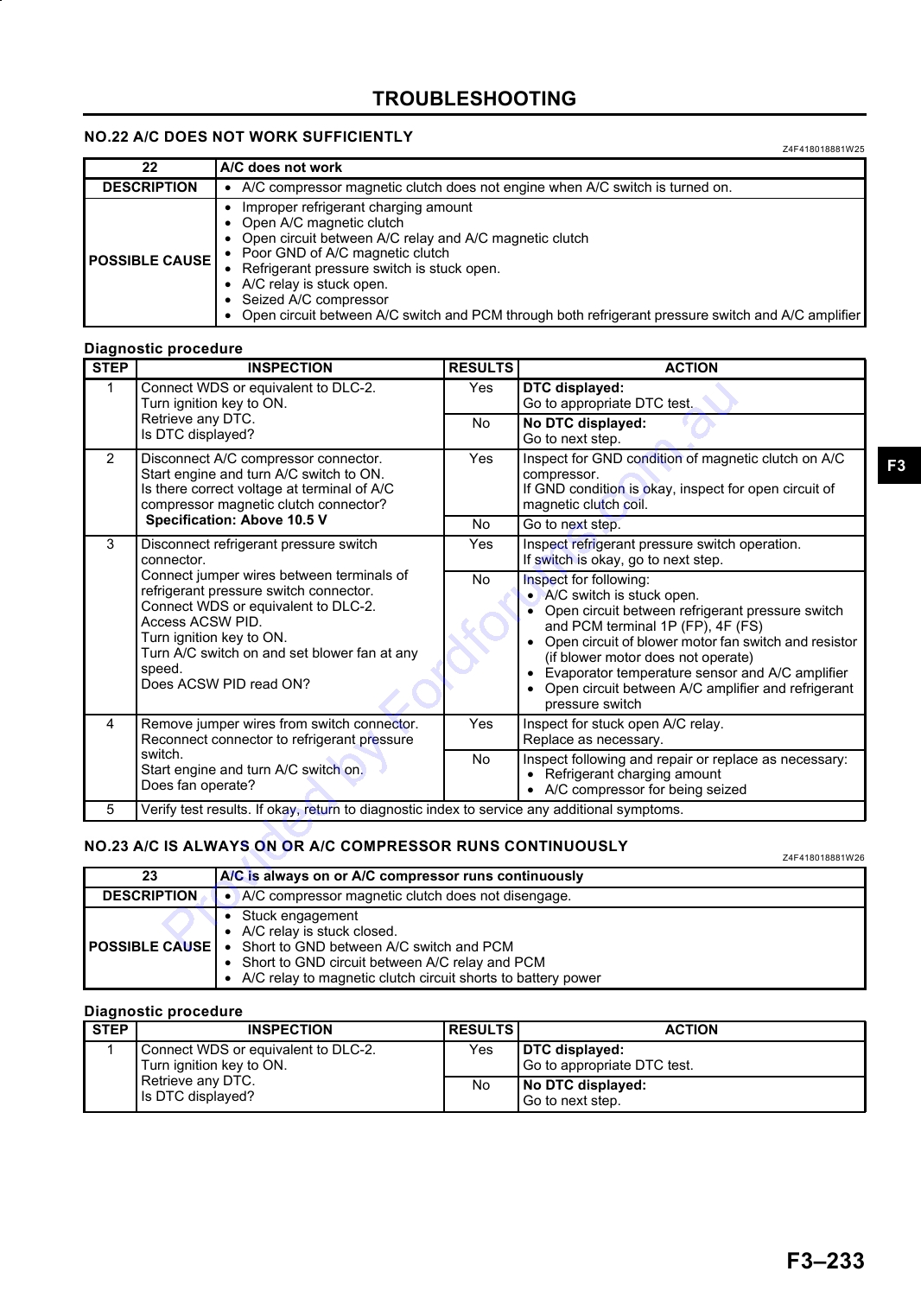

NO.22 A/C DOES NOT WORK

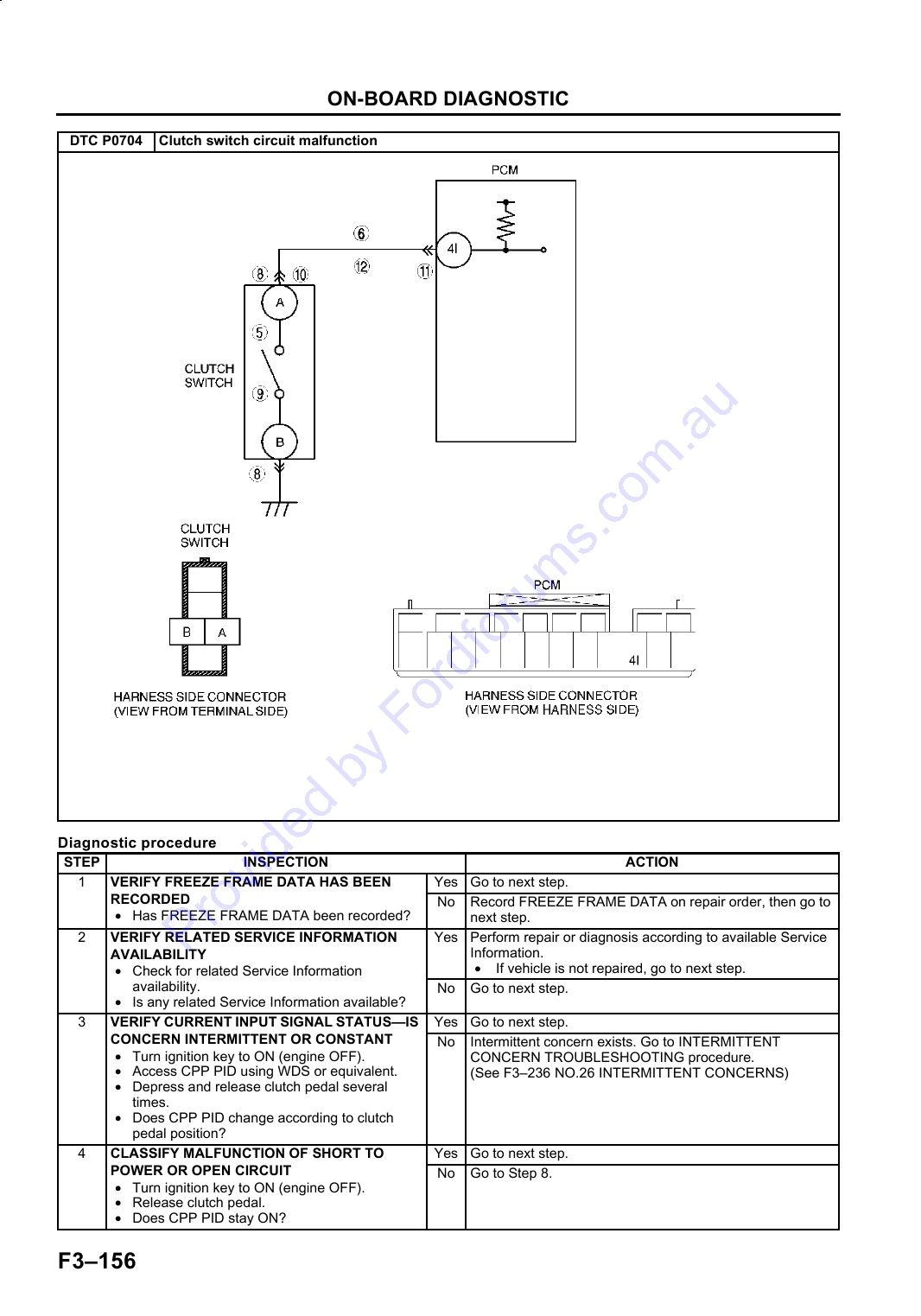

DTC P0704 (FS) ............................................ F3-155

SUFFICIENTLY........................................... F3-233

DTC P0705 (FS) ............................................ F3-158

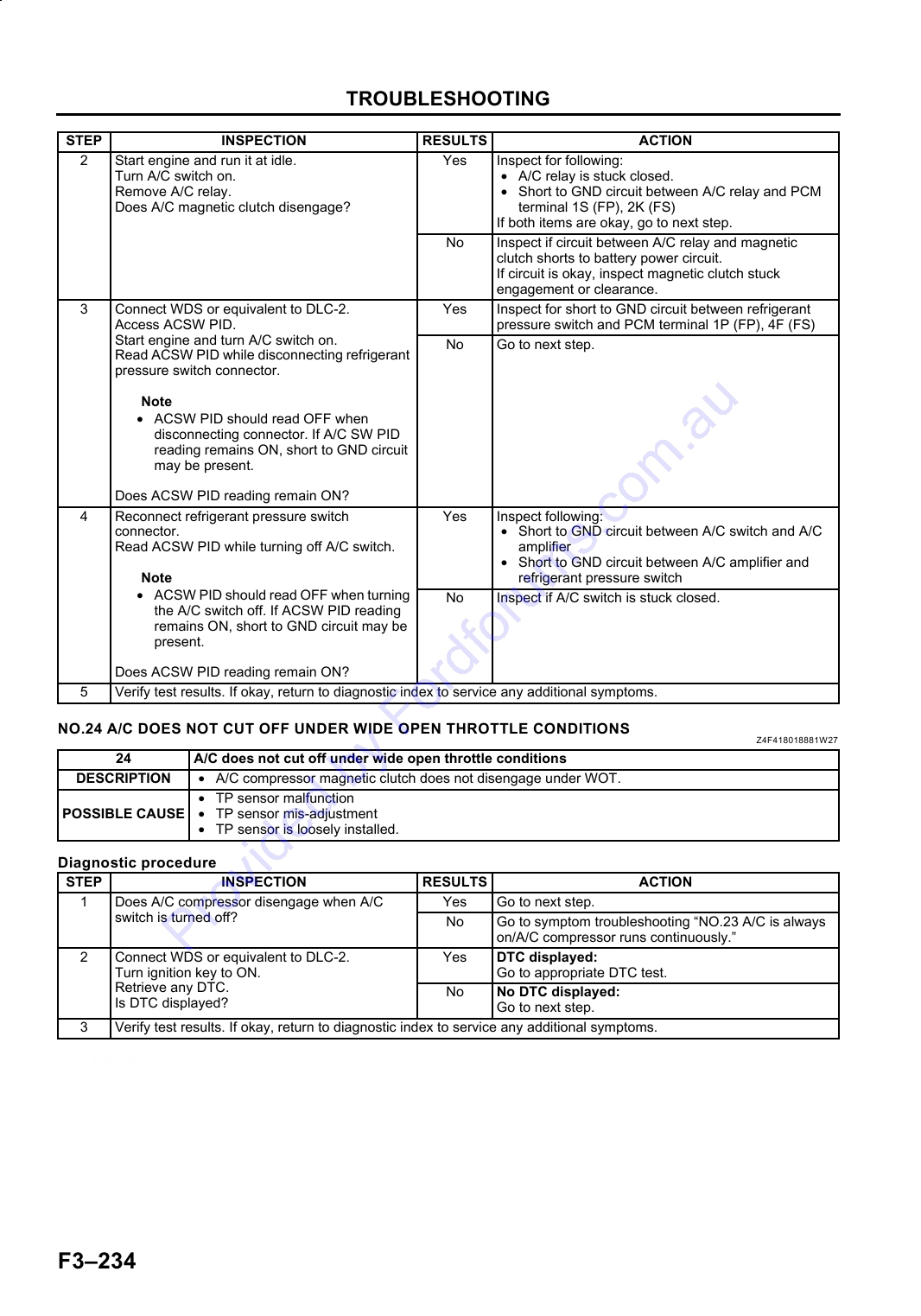

NO.23 A/C IS ALWAYS ON OR A/C

DTC P1102 (FS) ............................................ F3-160

COMPRESSOR RUNS CONTINUOUSLY . F3-233

DTC P1103 (FS) ............................................ F3-161

NO.24 A/C DOES NOT CUT OFF UNDER

DTC P1122 (FS) ............................................ F3-162

WIDE OPEN THROTTLE CONDITIONS .... F3-234

DTC P1123 (FS) ............................................ F3-164

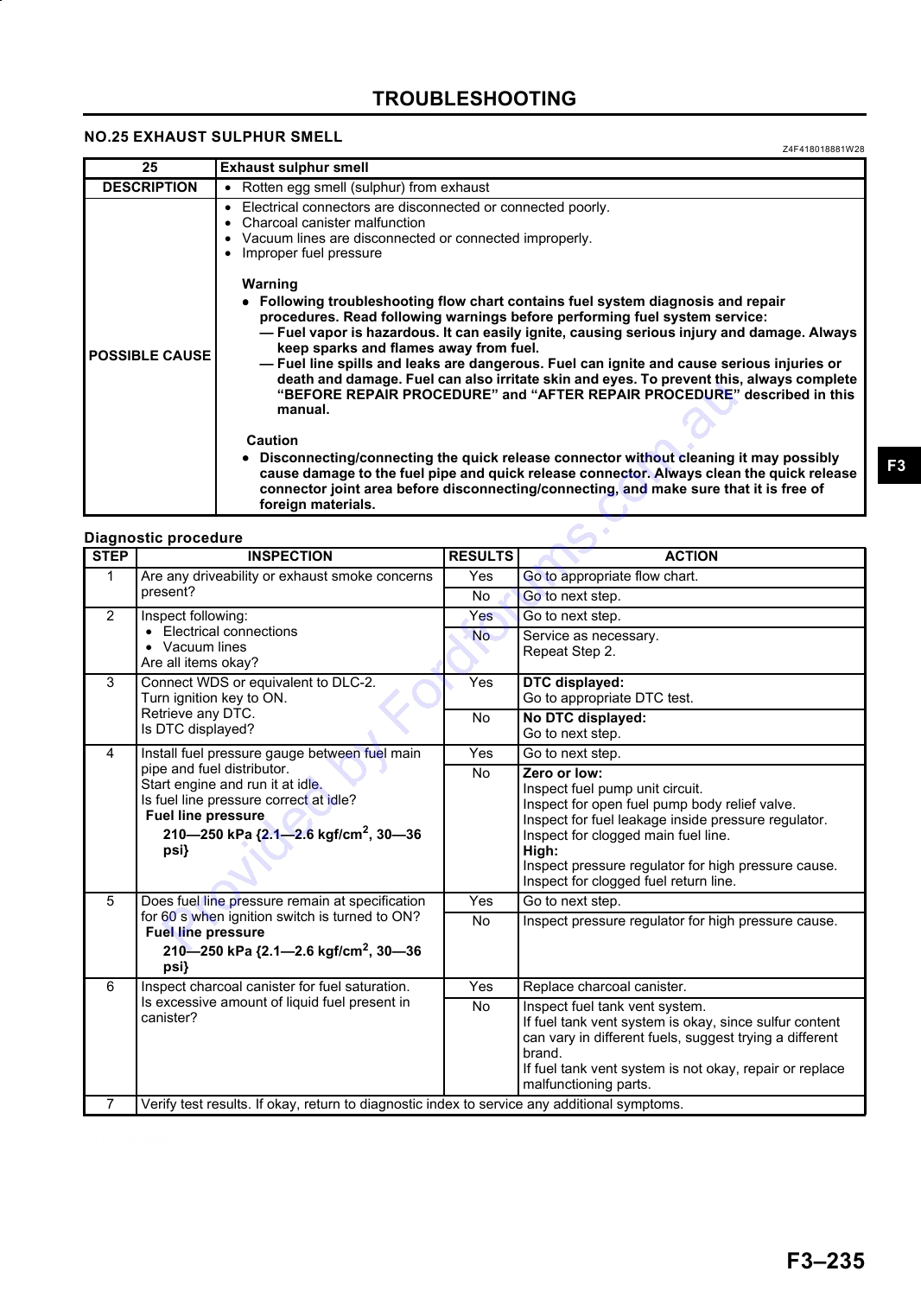

NO.25 EXHAUST SULPHUR SMELL ............ F3-235

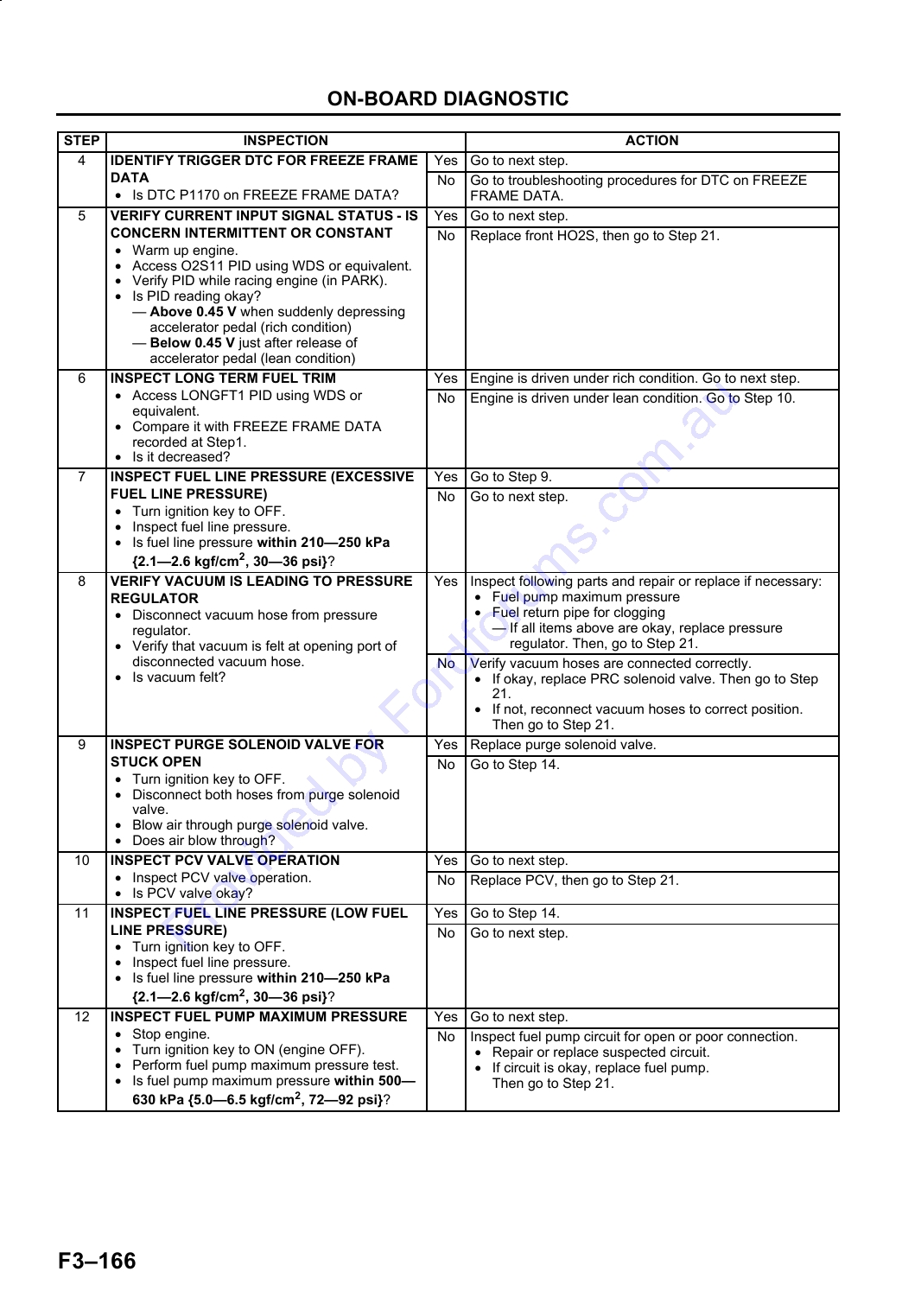

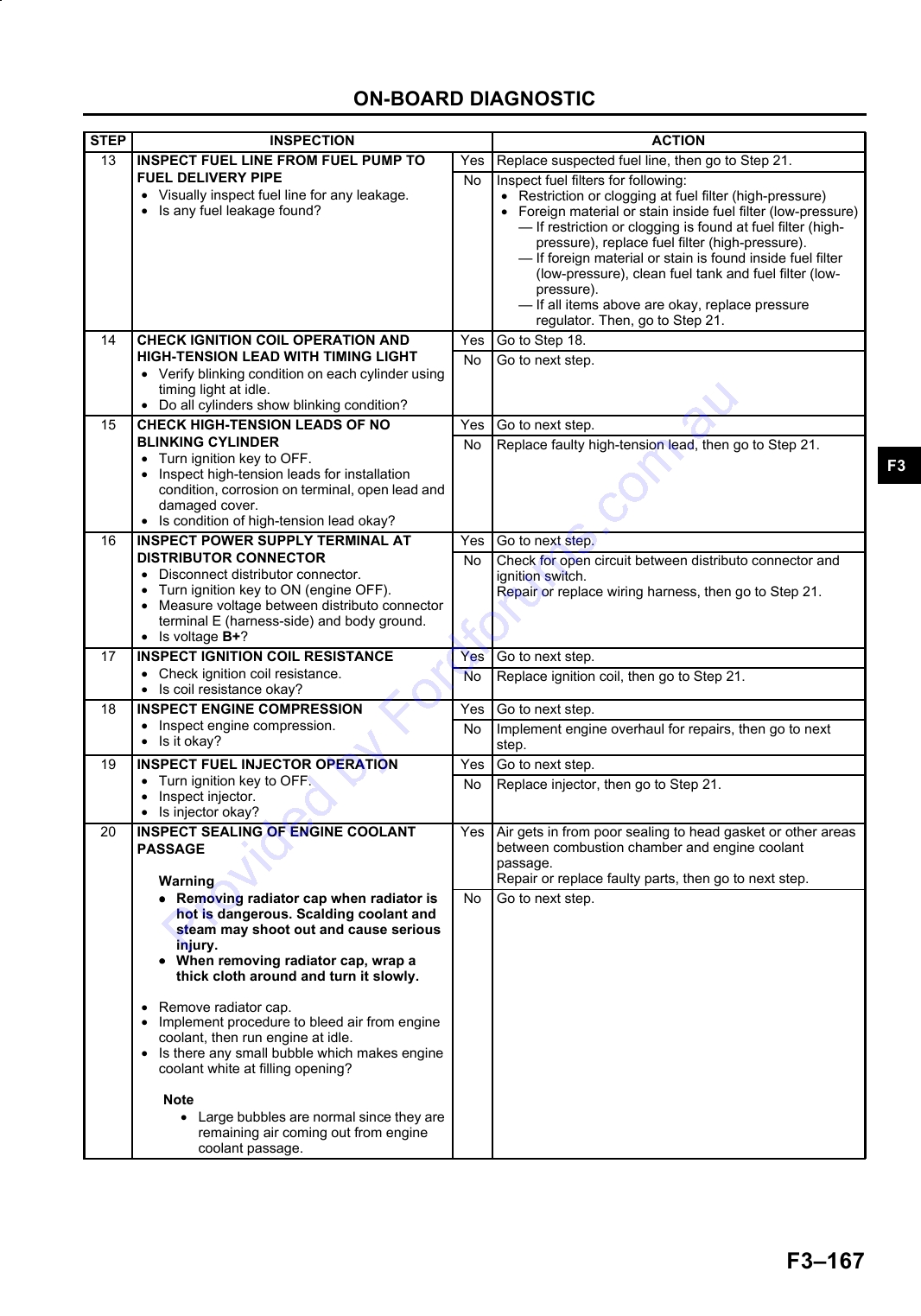

DTC P1170 (FS) ............................................ F3-165

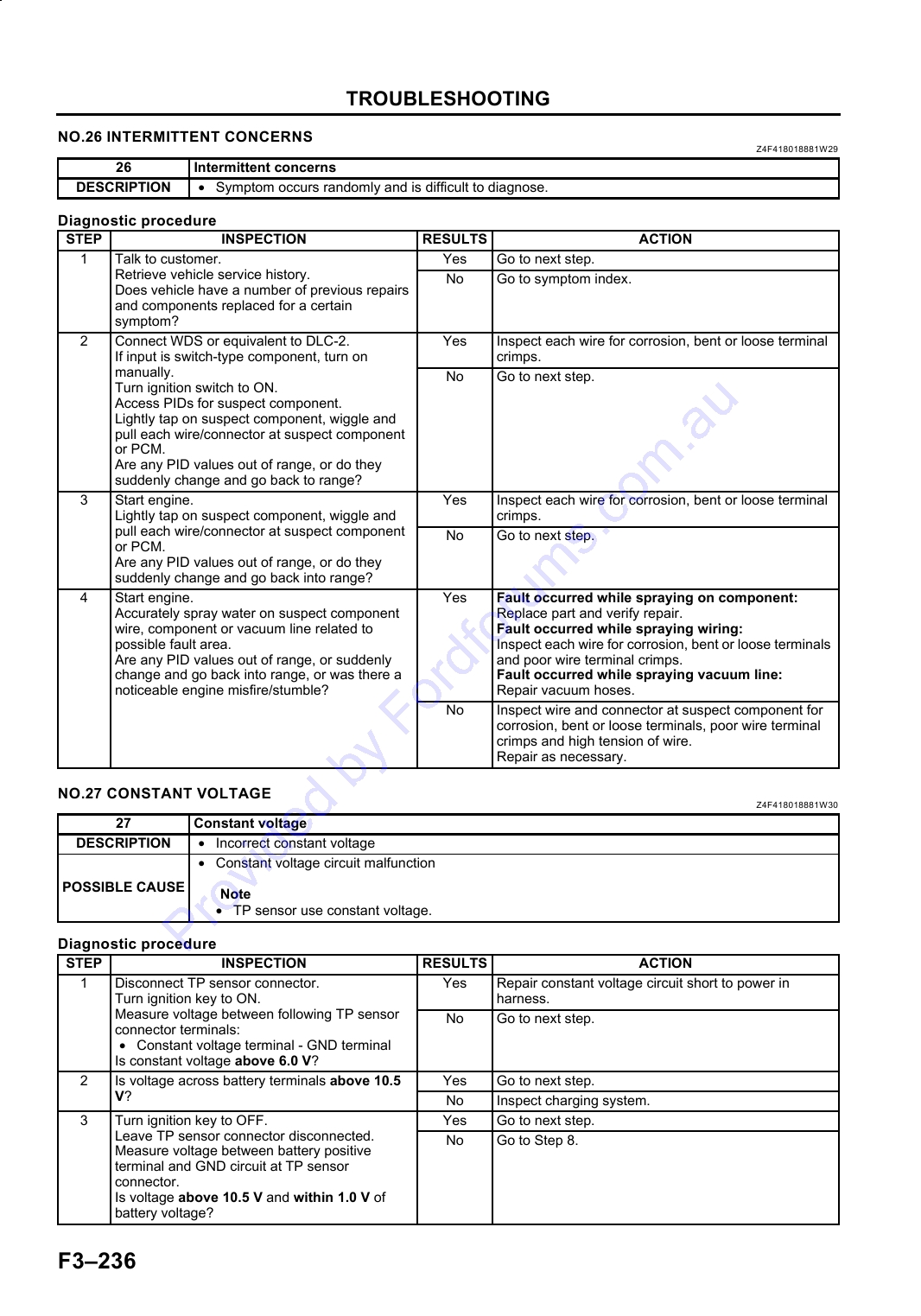

NO.26 INTERMITTENT CONCERNS ............ F3-236

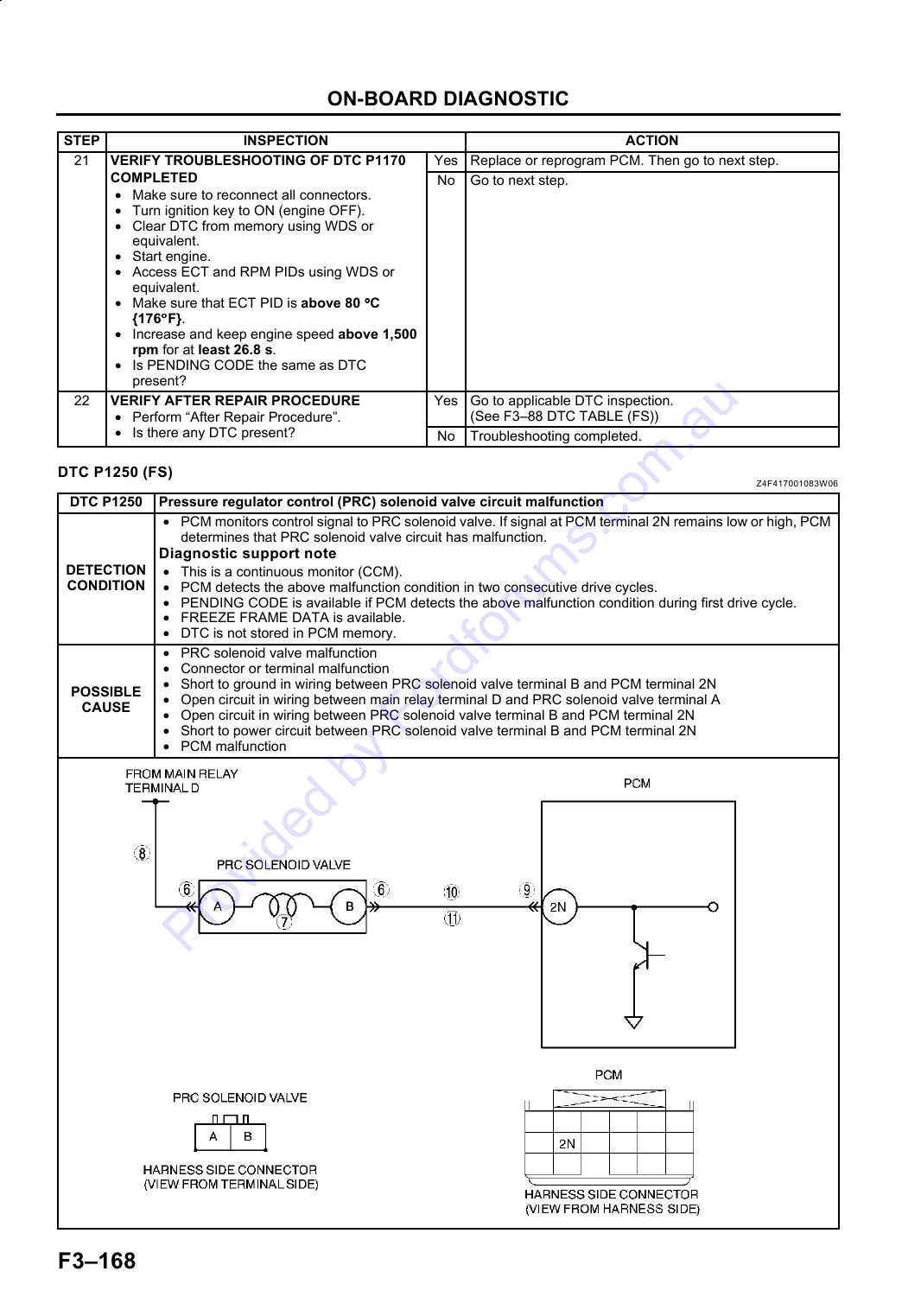

DTC P1250 (FS) ............................................ F3-168

NO.27 CONSTANT VOLTAGE ...................... F3-236

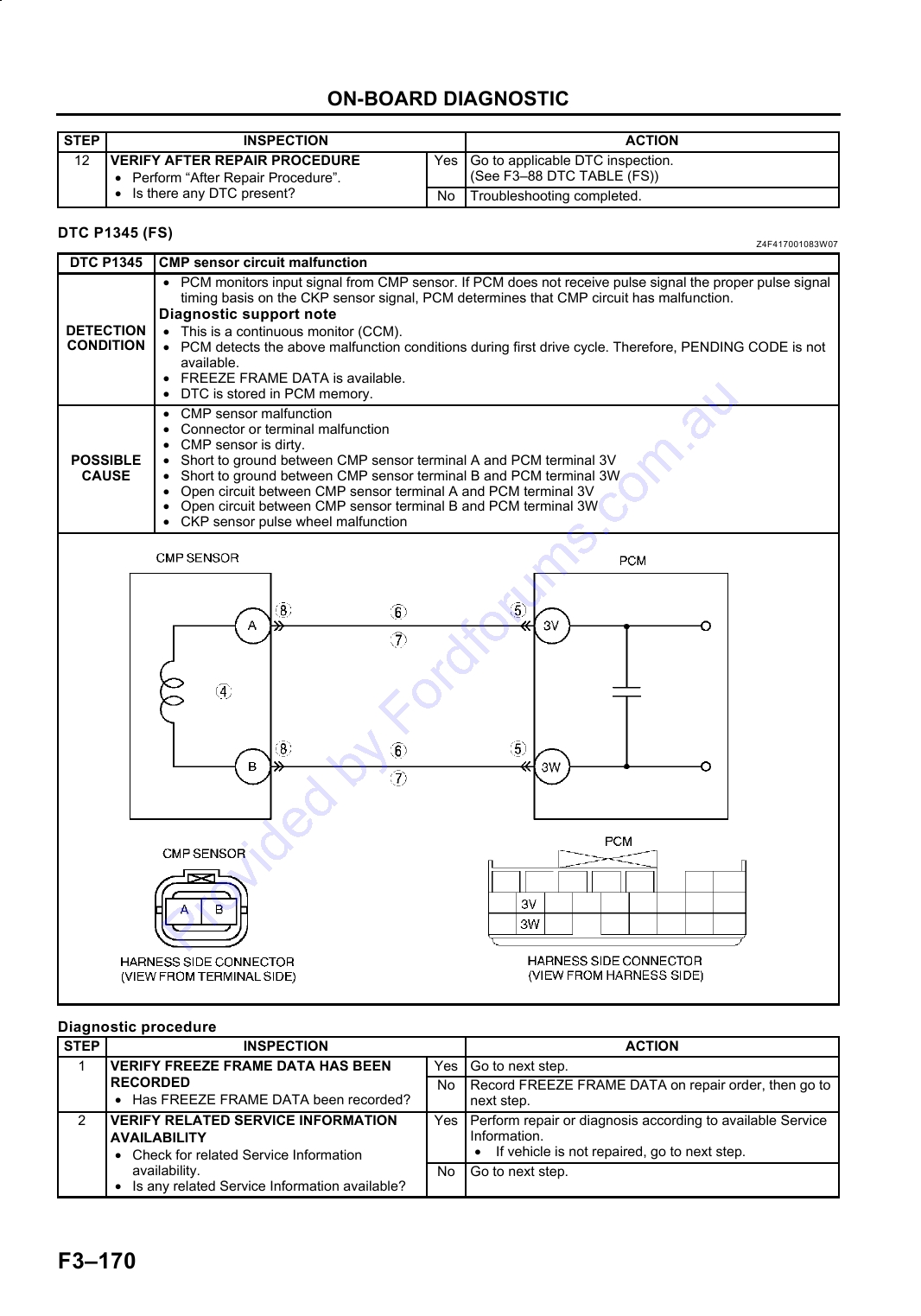

DTC P1345 (FS) ............................................ F3-170

ENGINE DIAGNOSTIC INSPECTION ........... F3-238

DTC P1496 (FS) ............................................ F3-172

ENGINE SYSTEM INSPECTION................... F3-240

DTC P1497 (FS) ............................................ F3-174

DTC P1498 (FS) ............................................ F3-176

DTC P1499 (FS) ............................................ F3-178

DTC P1504 (FS) ............................................ F3-180

DTC P1523 (FS) ............................................ F3-182

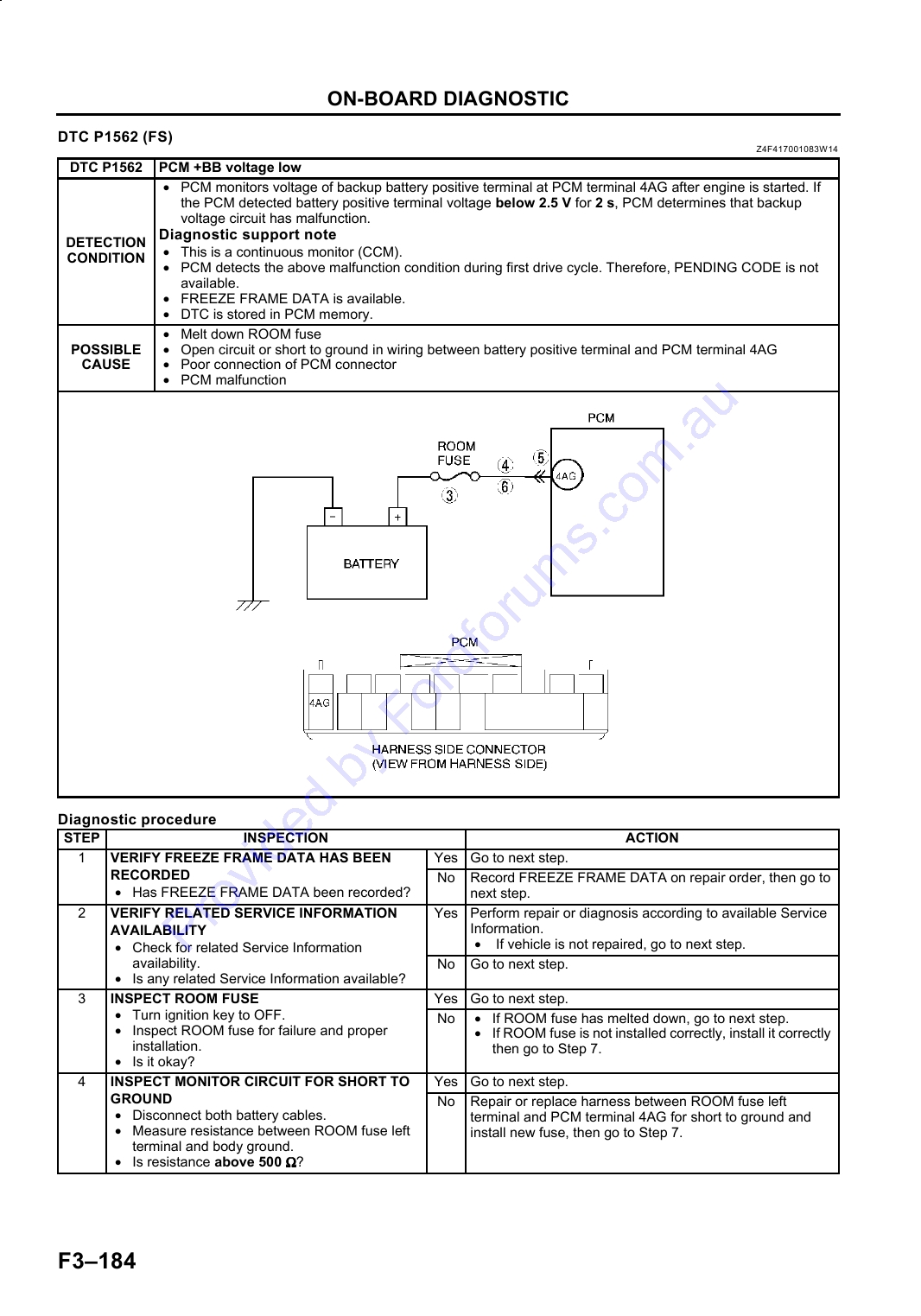

DTC P1562 (FS) ............................................ F3-184

DTC P1602 (FS) ............................................ F3-185

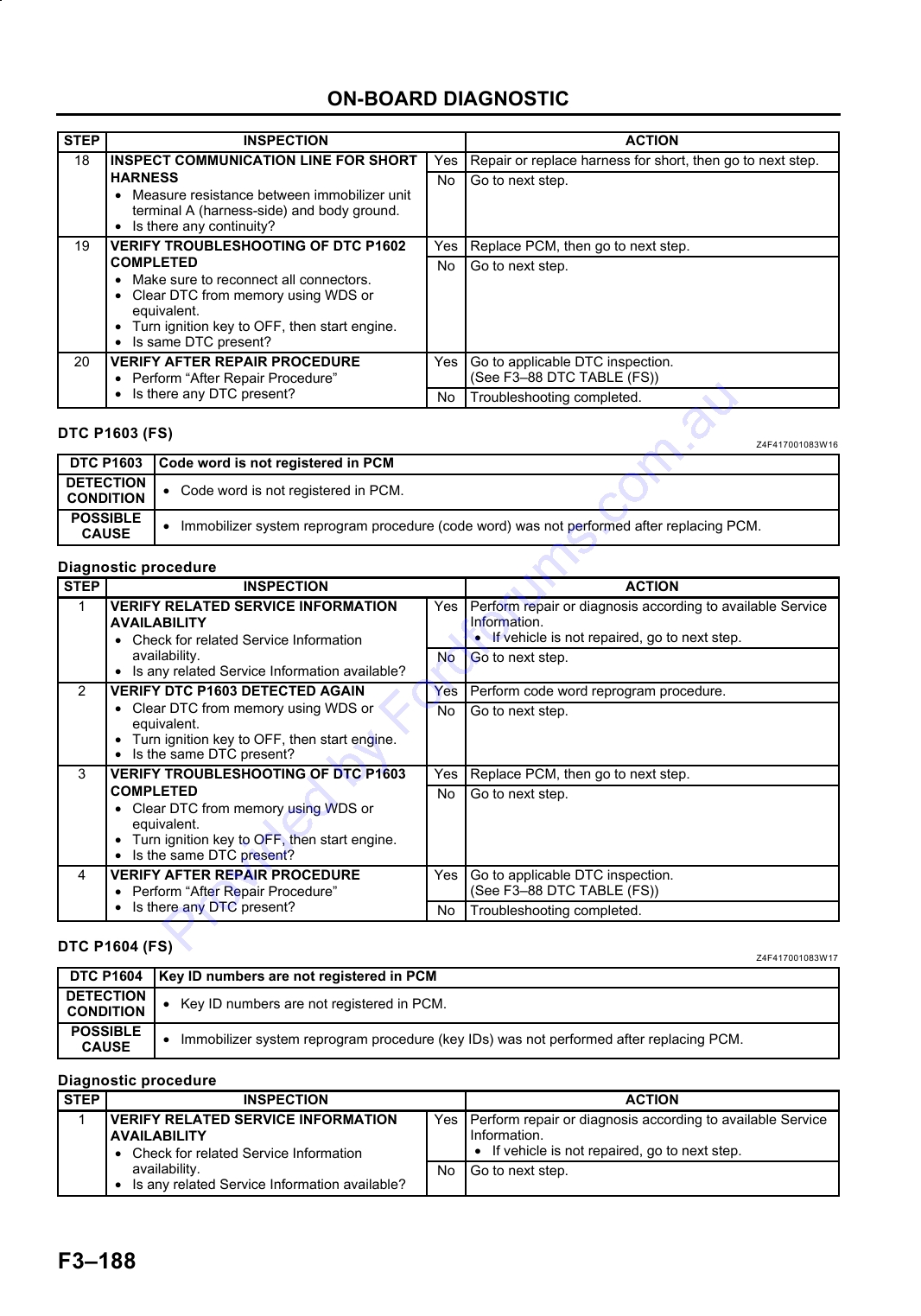

DTC P1603 (FS) ............................................ F3-188

DTC P1604 (FS) ............................................ F3-188

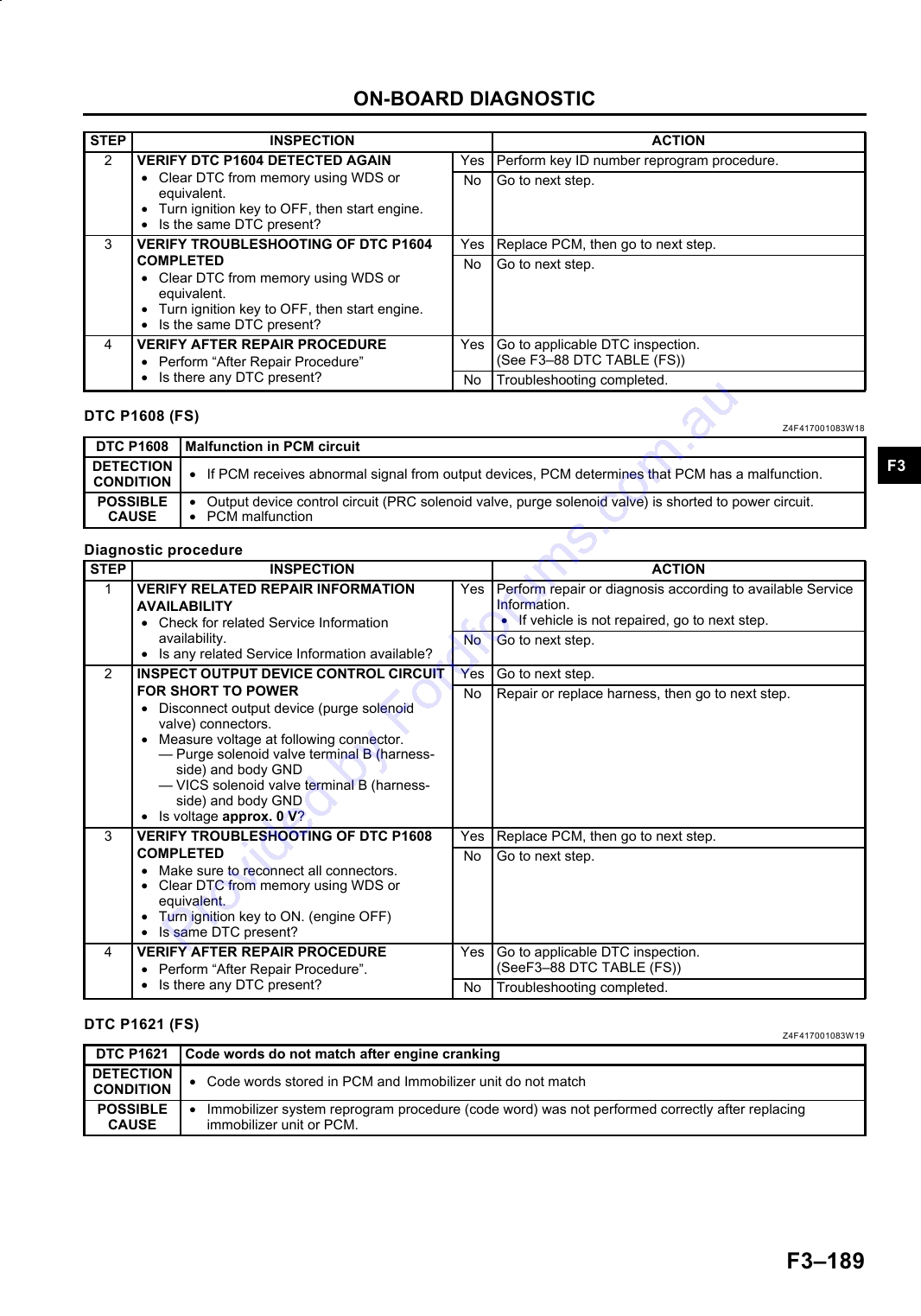

DTC P1608 (FS) ............................................ F3-189

DTC P1621 (FS) ............................................ F3-189

DTC P1622 (FS) ............................................ F3-190

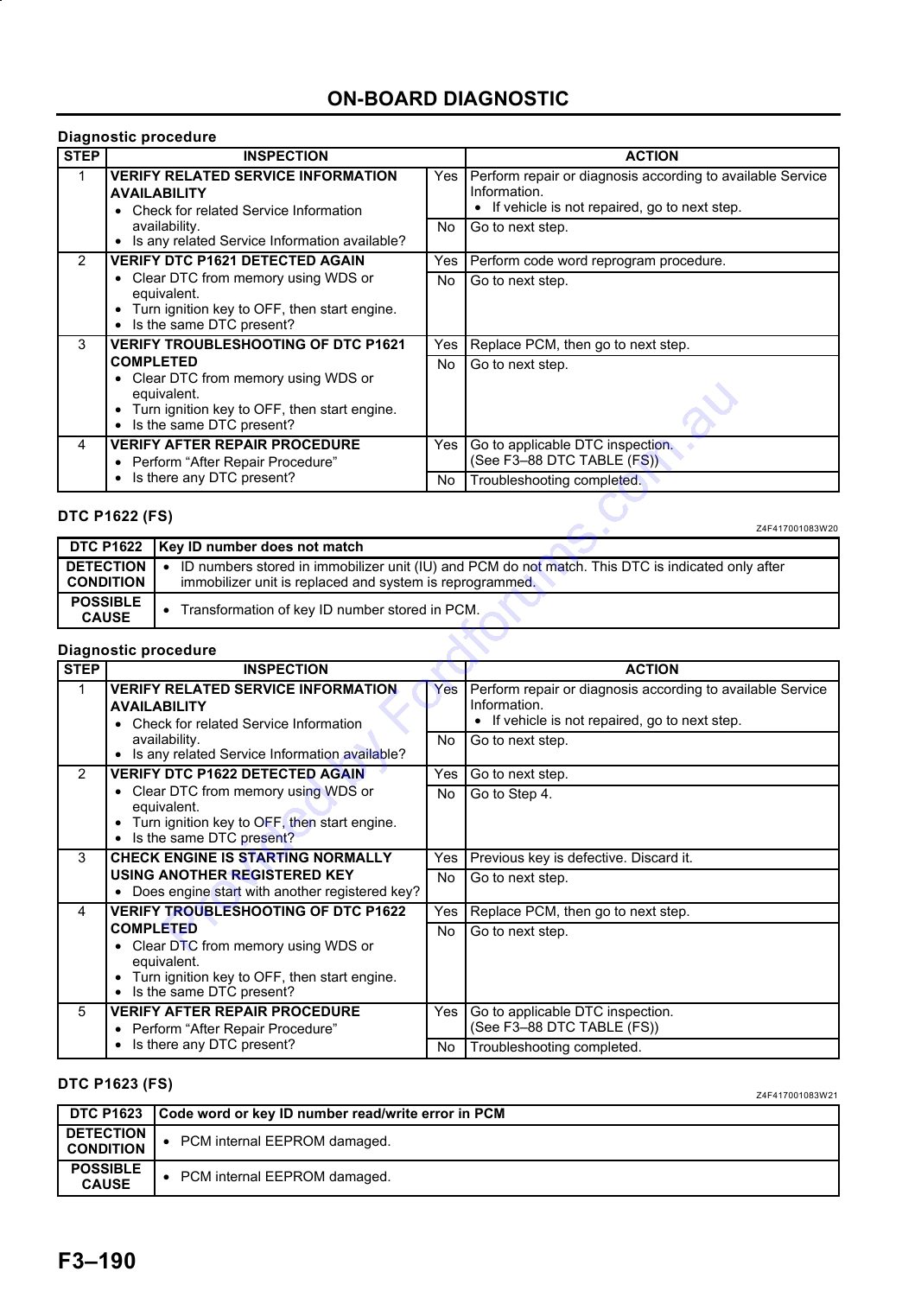

DTC P1623 (FS) ............................................ F3-190

DTC P1624 (FS) ............................................ F3-191

DTC P1631 (FS) ............................................ F3-191

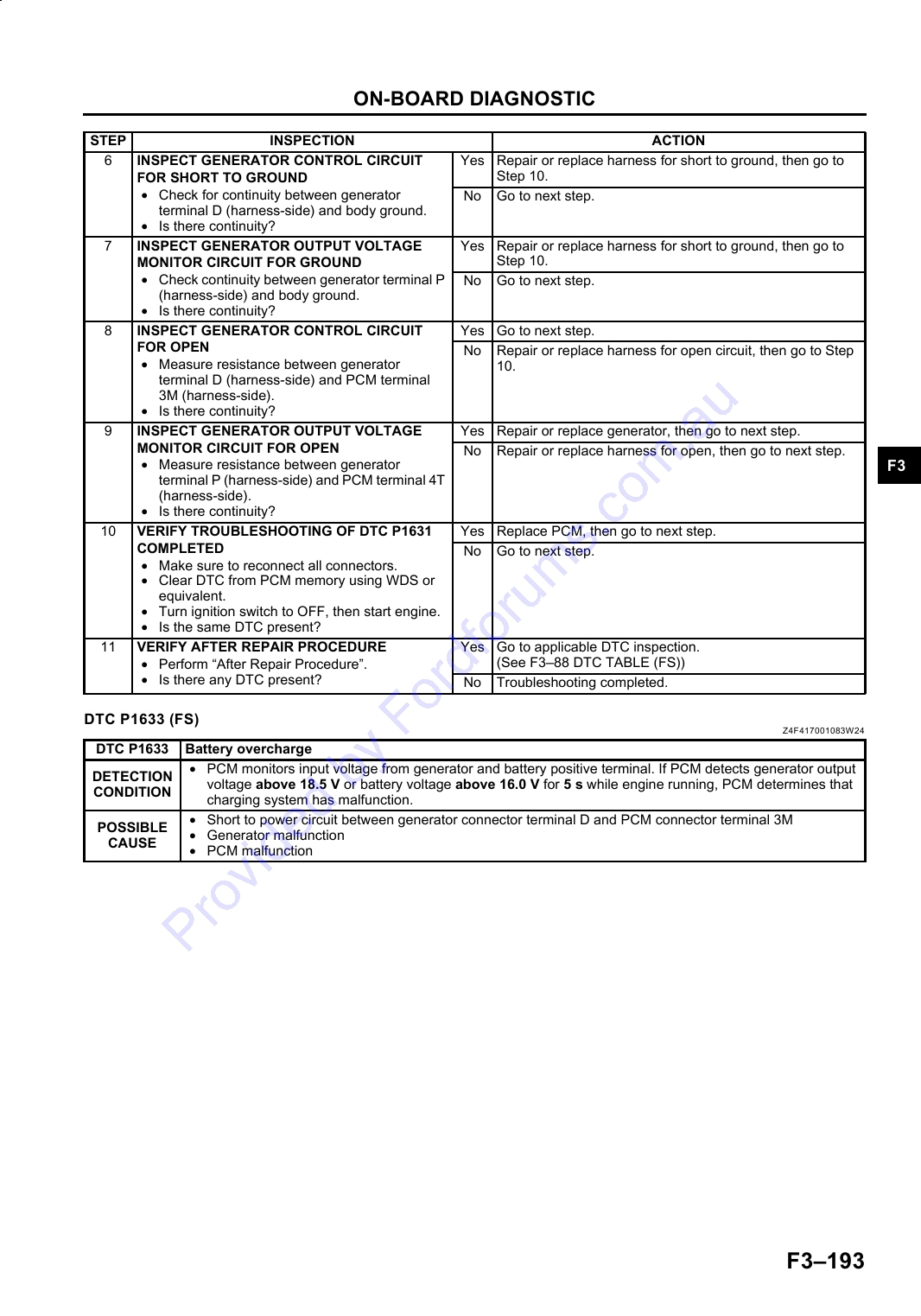

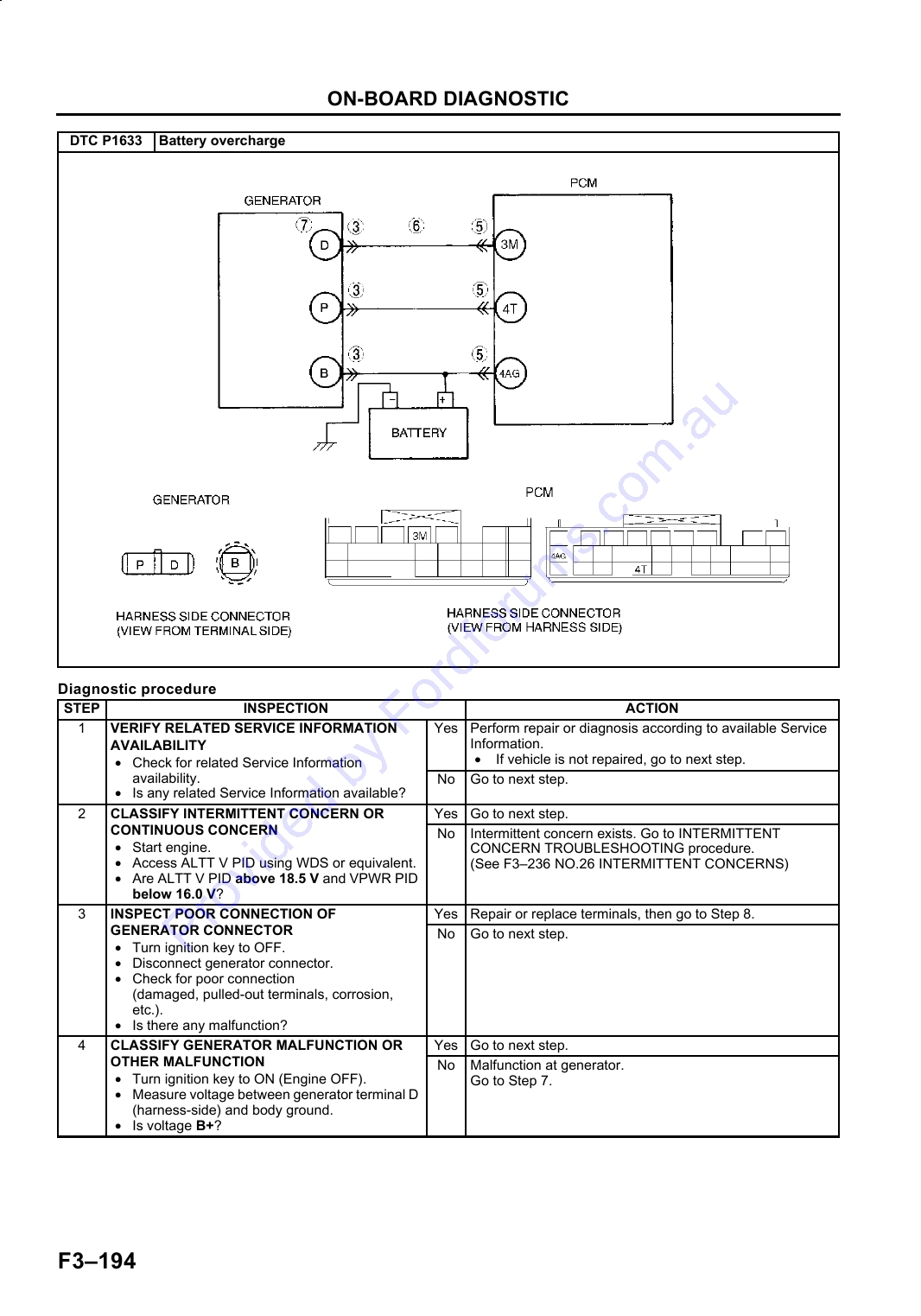

DTC P1633 (FS) ............................................ F3-193

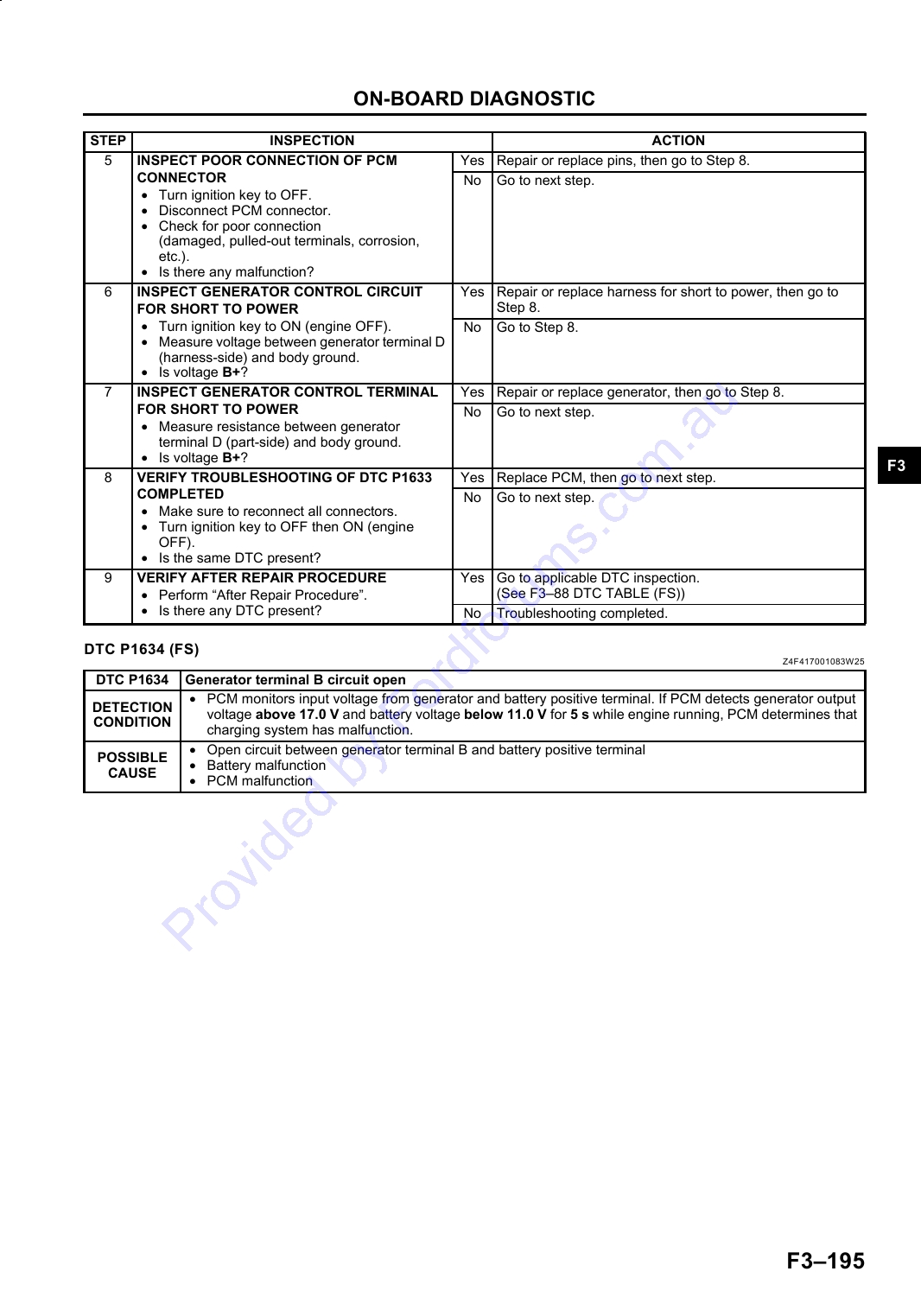

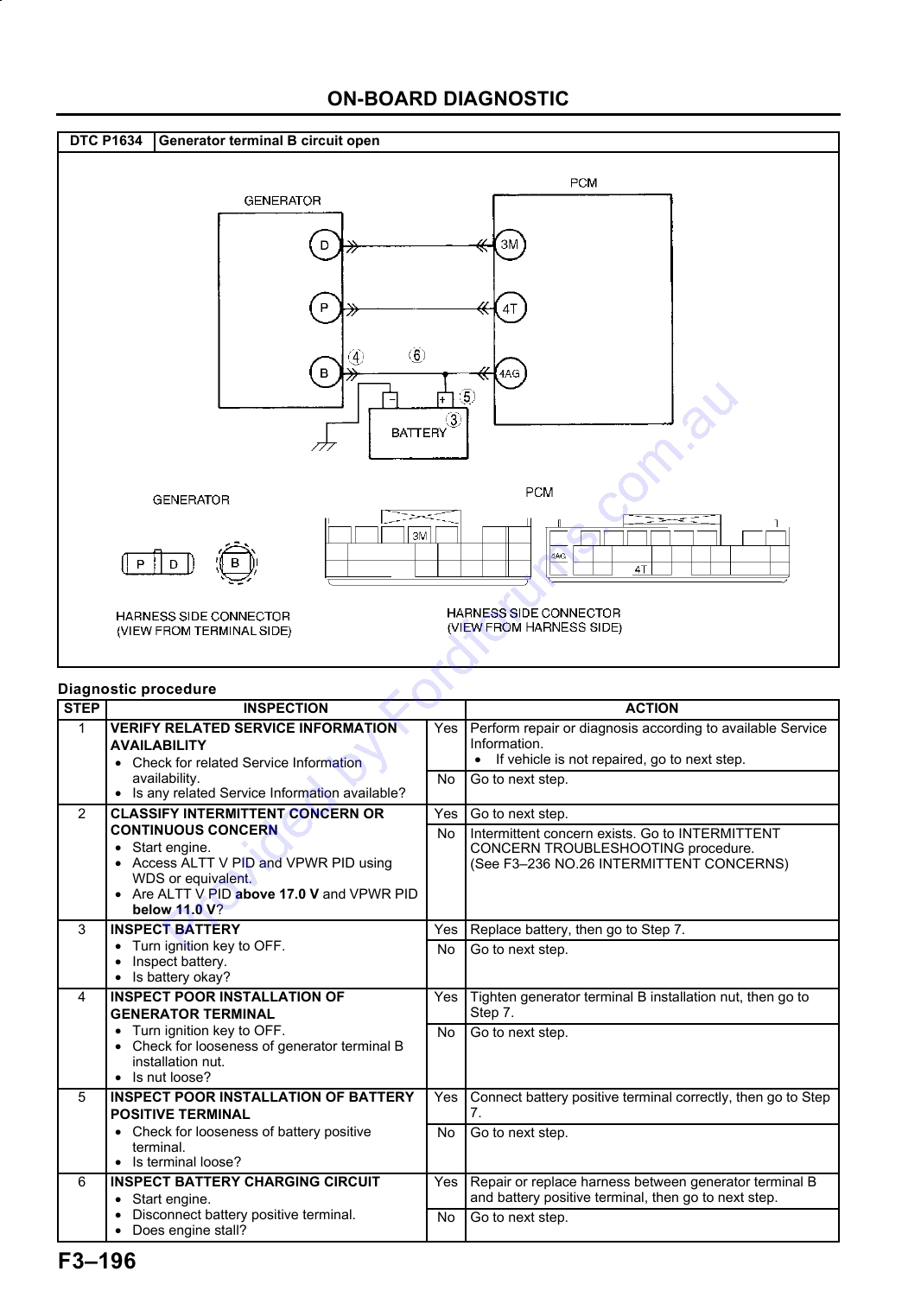

DTC P1634 (FS) ............................................ F3-195

F32

OUTLINE

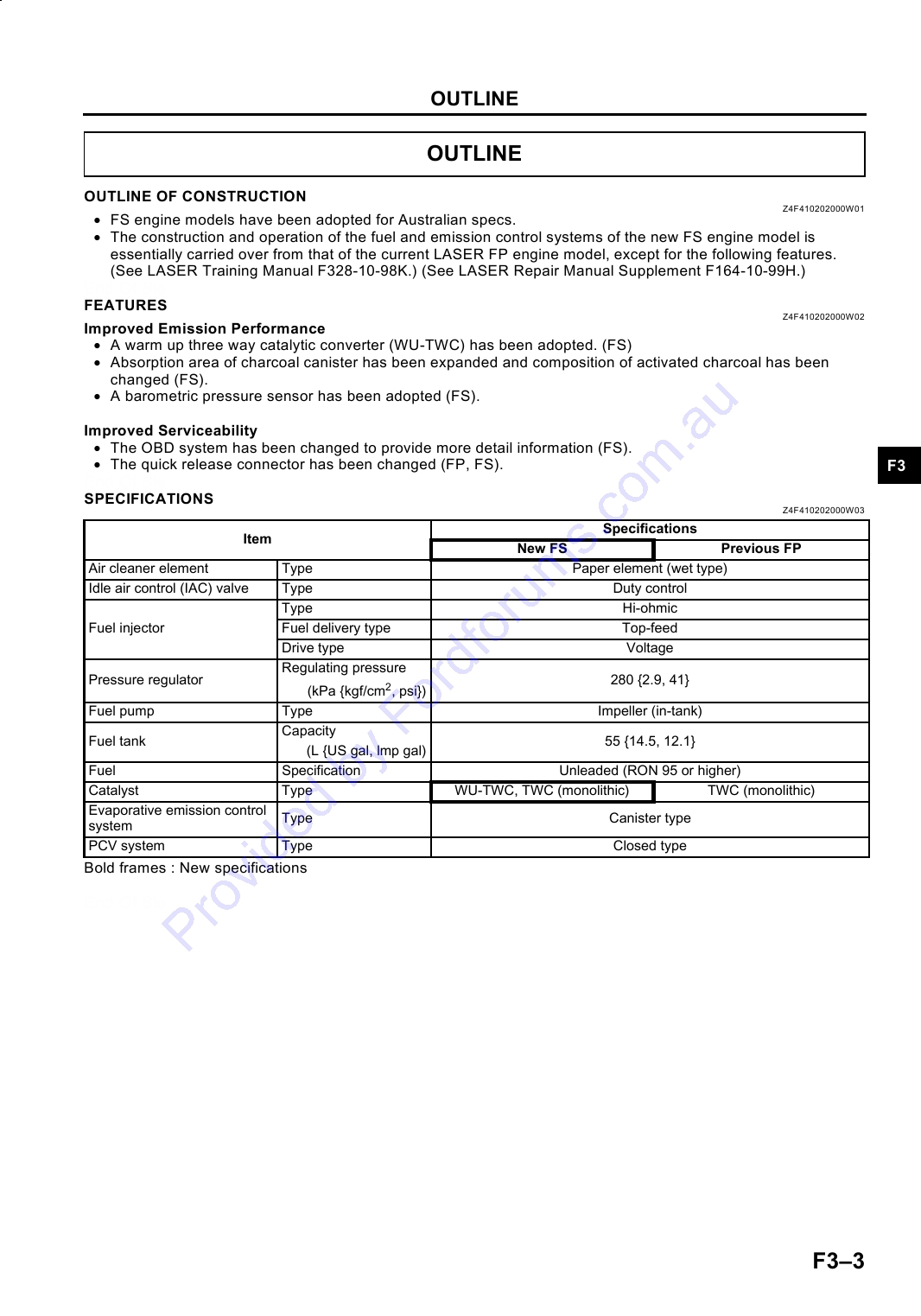

OUTLINE

OUTLINE OF CONSTRUCTION

Z4F410202000W01

· FS engine models have been adopted for Australian specs.

· The construction and operation of the fuel and emission control systems of the new FS engine model is

essentially carried over from that of the current LASER FP engine model, except for the following features.

(See LASER Training Manual F328-10-98K.) (See LASER Repair Manual Supplement F164-10-99H.)

End Of Sie

FEATURES

Z4F410202000W02

Improved Emission Performance

· A warm up three way catalytic converter (WU-TWC) has been adopted. (FS)

· Absorption area of charcoal canister has been expanded and composition of activated charcoal has been

changed (FS).

· A barometric pressure sensor has been adopted (FS).

Improved Serviceability

· The OBD system has been changed to provide more detail information (FS).

· The quick release connector has been changed (FP, FS).

F3

End Of Sie

SPECIFICATIONS

Z4F410202000W03

Specifications

Item

New FS

Previous FP

Air cleaner element

Type

Paper element (wet type)

Idle air control (IAC) valve

Type

Duty control

Type

Hi-ohmic

Fuel injector

Fuel delivery type

Top-feed

Drive type

Voltage

Regulating pressure

Pressure regulator

280 {2.9, 41}

(kPa {kgf/cm2, psi})

Fuel pump

Type

Impeller (in-tank)

Capacity

Fuel tank

55 {14.5, 12.1}

(L {US gal, lmp gal)

Fuel

Specification

Unleaded (RON 95 or higher)

Catalyst

Type

WU-TWC, TWC (monolithic)

TWC (monolithic)

Evaporative emission control

Type

Canister type

system

PCV system

Type

Closed type

Bold frames : New specifications

End Of Sie

F33

OUTLINE

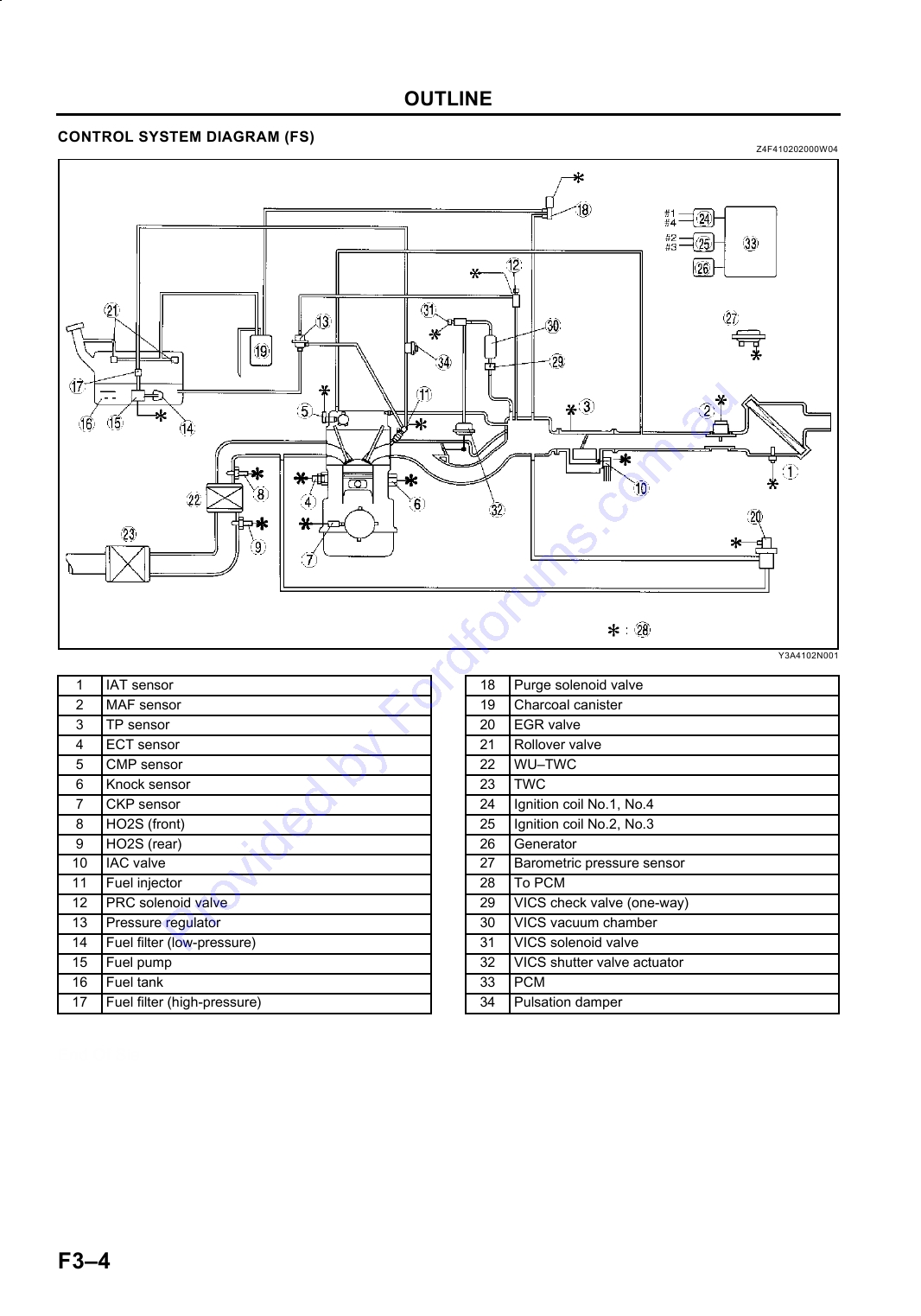

CONTROL SYSTEM DIAGRAM (FS)

Z4F410202000W04

Y3A4102N001

.

1

IAT sensor

18

Purge solenoid valve

2

MAF sensor

19

Charcoal canister

3

TP sensor

20

EGR valve

4

ECT sensor

21

Rollover valve

5

CMP sensor

22

WUTWC

6

Knock sensor

23

TWC

7

CKP sensor

24

Ignition coil No.1, No.4

8

HO2S (front)

25

Ignition coil No.2, No.3

9

HO2S (rear)

26

Generator

10

IAC valve

27

Barometric pressure sensor

11

Fuel injector

28

To PCM

12

PRC solenoid valve

29

VICS check valve (one-way)

13

Pressure regulator

30

VICS vacuum chamber

14

Fuel filter (low-pressure)

31

VICS solenoid valve

15

Fuel pump

32

VICS shutter valve actuator

16

Fuel tank

33

PCM

17

Fuel filter (high-pressure)

34

Pulsation damper

End Of Sie

F34

OUTLINE

F3

F35

OUTLINE

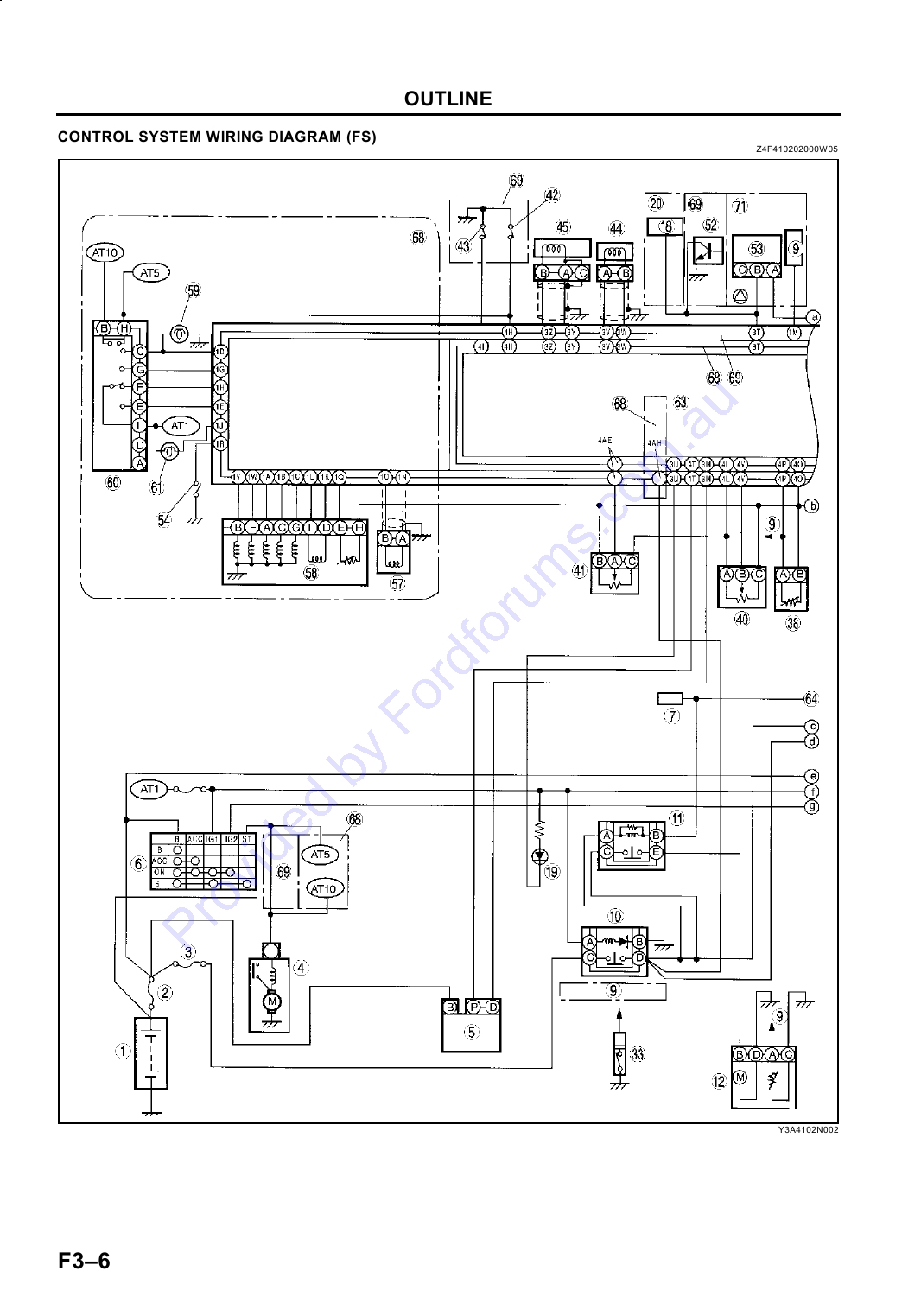

CONTROL SYSTEM WIRING DIAGRAM (FS)

Z4F410202000W05

Y3A4102N002

F36

OUTLINE

F3

Y3E4102N003

.

F37

OUTLINE

1

Battery

37

PRC solenoid valve

2

Main fuse

38

ECT sensor

3

INJ fuse

39

IAT sensor

4

Starter

40

TP sensor

5

Generator

41

Barometric pressure sensor

6

Ignition switch

42

Neutral switch

7

DLC

43

Clutch switch

8

DSC unit

44

CMP sensor

9

To instrument cluster

45

CKP sensor

10

Main relay

46

Fuel injector No.1

11

Fuel pump relay

47

Fuel injector No.2

12

Fuel pump unit

48

Fuel injector No.3

13

PSP switch

49

Fuel injector No.4

14

HO2S (rear)

50

Condenser

15

HO2S (front)

51

Ignition coil

16

EGR valve

52

VSS (integrated with instrument cluster)

17

MAF sensor

53

VSS

18

To ABS

54

Hold switch

19

Generator warning light

55

Brake light

20

For ATX model (with ABS)

56

Brake switch

21

Blower motor

57

Input/turbine speed sensor

22

VICS solenoid valve

58

EC-AT solenoid

23

Fan switch

59

Back-up light

24

A/C relay

60

TR switch

25

A/C switch

61

Hold indicator light

26

A/C amplifier

62

Knock sensor

27

Refrigerant pressure switch

63

PCM

28

A/C compressor

64

Terminal 2M in PCM

29

Condenser fan relay

65

DLC-2

30

Condenser fan motor

66

Microcomputer (DIS)

31

Cooling fan relay

67

Refrigerant pressure switch

32

Cooling fan motor

68

For ATX model

33

Oil pressure switch

69

For MTX model

34

Immobilizer unit

70

A/C equipped only

35

IAC valve

71

For ATX model (without ABS)

36

Purge solenoid valve

End Of Sie

F38

FUEL SYSTEM

FUEL SYSTEM

OUTLINE

Z4F411201006W01

· The construction and operation of the fuel systems of the face-lifted FP engine models and new FS engine

models are essentially carried over from that of the current LASER FP engine models, except for the following.

-- The quick release connector (engine room side) has been changed.

End Of Sie

STRUCTURAL VIEW

Z4F411201006W02

F3

Y3E4112N001

.

1

Pulsation damper

5

Quick release connector

2

Fuel injector

6

Fuel pump relay

3

Pressure regulator

7

To fuel tank

4

PRC solenoid valve

8

From fuel tank

End Of Sie

F39

FUEL SYSTEM

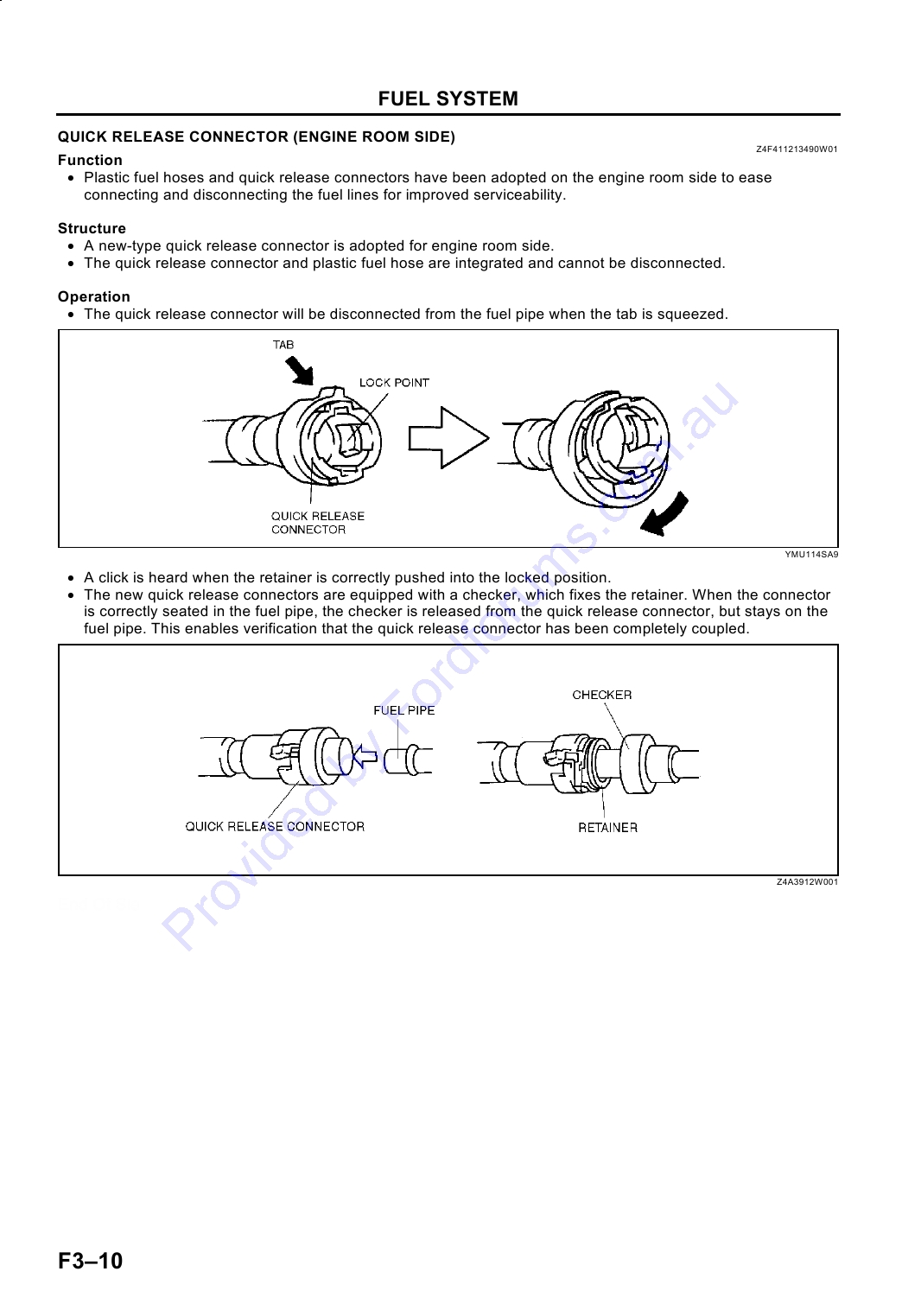

QUICK RELEASE CONNECTOR (ENGINE ROOM SIDE)

Z4F411213490W01

Function

· Plastic fuel hoses and quick release connectors have been adopted on the engine room side to ease

connecting and disconnecting the fuel lines for improved serviceability.

Structure

· A new-type quick release connector is adopted for engine room side.

· The quick release connector and plastic fuel hose are integrated and cannot be disconnected.

Operation

· The quick release connector will be disconnected from the fuel pipe when the tab is squeezed.

YMU114SA9

· A click is heard when the retainer is correctly pushed into the locked position.

· The new quick release connectors are equipped with a checker, which fixes the retainer. When the connector

is correctly seated in the fuel pipe, the checker is released from the quick release connector, but stays on the

fuel pipe. This enables verification that the quick release connector has been completely coupled.

Z4A3912W001

End Of Sie

F310

FUEL SYSTEM

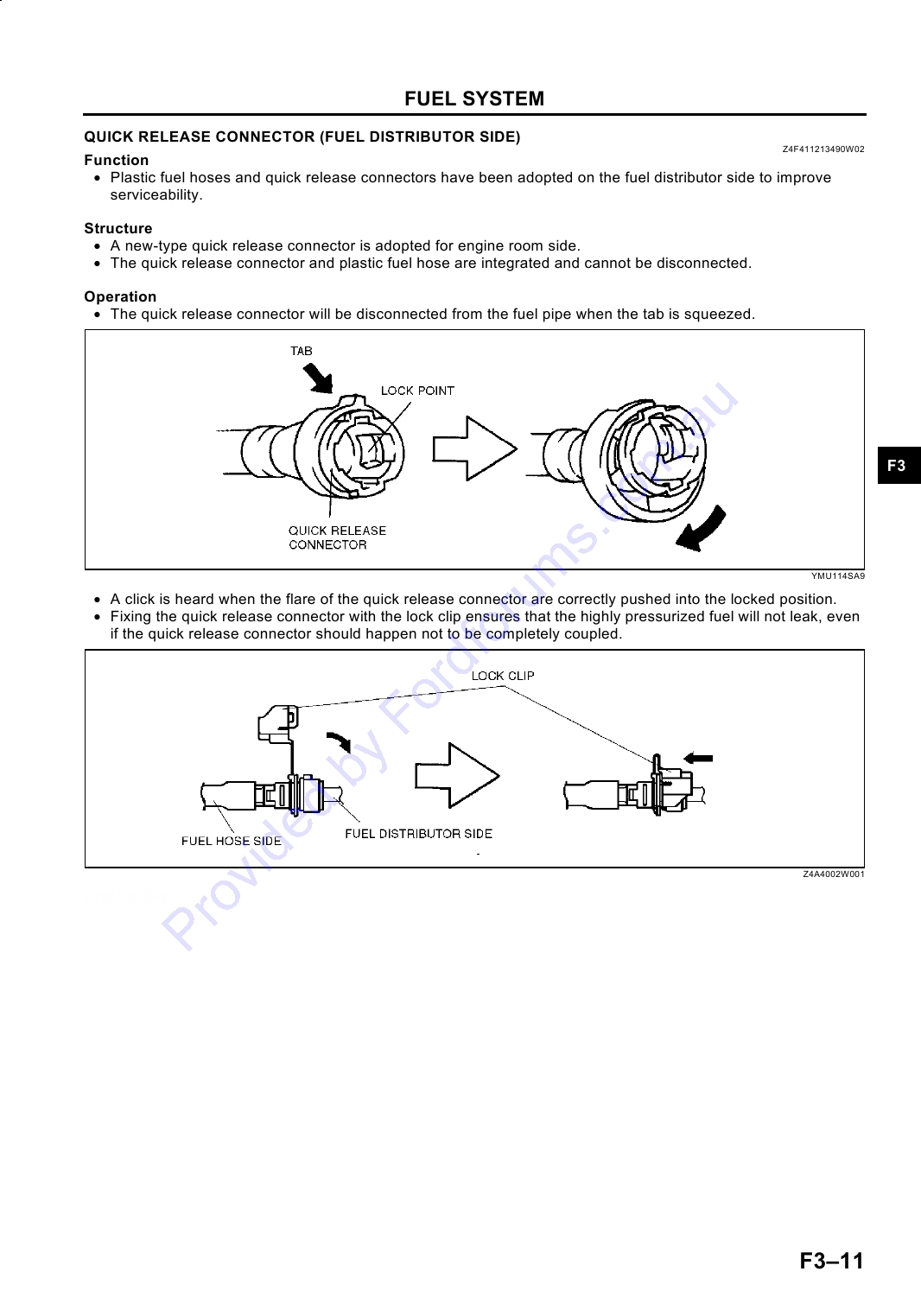

QUICK RELEASE CONNECTOR (FUEL DISTRIBUTOR SIDE)

Z4F411213490W02

Function

· Plastic fuel hoses and quick release connectors have been adopted on the fuel distributor side to improve

serviceability.

Structure

· A new-type quick release connector is adopted for engine room side.

· The quick release connector and plastic fuel hose are integrated and cannot be disconnected.

Operation

· The quick release connector will be disconnected from the fuel pipe when the tab is squeezed.

F3

YMU114SA9

· A click is heard when the flare of the quick release connector are correctly pushed into the locked position.

· Fixing the quick release connector with the lock clip ensures that the highly pressurized fuel will not leak, even

if the quick release connector should happen not to be completely coupled.

Z4A4002W001

End Of Sie

F311

EMISSION SYSTEM

EMISSION SYSTEM

OUTLINE

Z4F411601007W01

· The construction and operation of the emission systems of the new FS engine models is essentially carried

over from that of the cuurent LASER FP engine models, except for the following.

-- The warm up three way catalytic converter (WU-TWC) has been adopted between the exhaust manifold

and front pipe to improve emission performance.

-- Absorption area of charcoal canister has been expended and composition of activated charcoal has been

changed.

End Of Sie

STRUCTURAL VIEW (FS)

Z4F411601007W02

Engine Room Side

Y3A4116N001

.

1

Charcoal canister

4

PCV valve

2

Purge solenoid valve

5

WU-TWC

3

EGR valve

End Of Sie

F312

EMISSION SYSTEM

CHARCOAL CANISTER (FS)

Z4F411613970W01

· A U-flow type charcoal canister whose internal flow shaped like a U has been adopted.

YPE3916W001

· The incorporation of this type of charcoal expands the area of absorption, increasing the amount of fuel

evaporative emission particulate absorption. Absorption efficiency enhanced activated charcoal has also been

adopted.

End Of Sie

F3

WARM UP THREE WAY CATALYTIC CONVERTER (WU-TWC) (FS)

Z4F411620505W01

· The WU-TWC warms up and energizes quickly after the engine starts, so exhaust gas conversion to less

harmful emissions starts earlier at cold engine start up.

End Of Sie

F313

CONTROL SYSTEM

CONTROL SYSTEM

OUTLINE

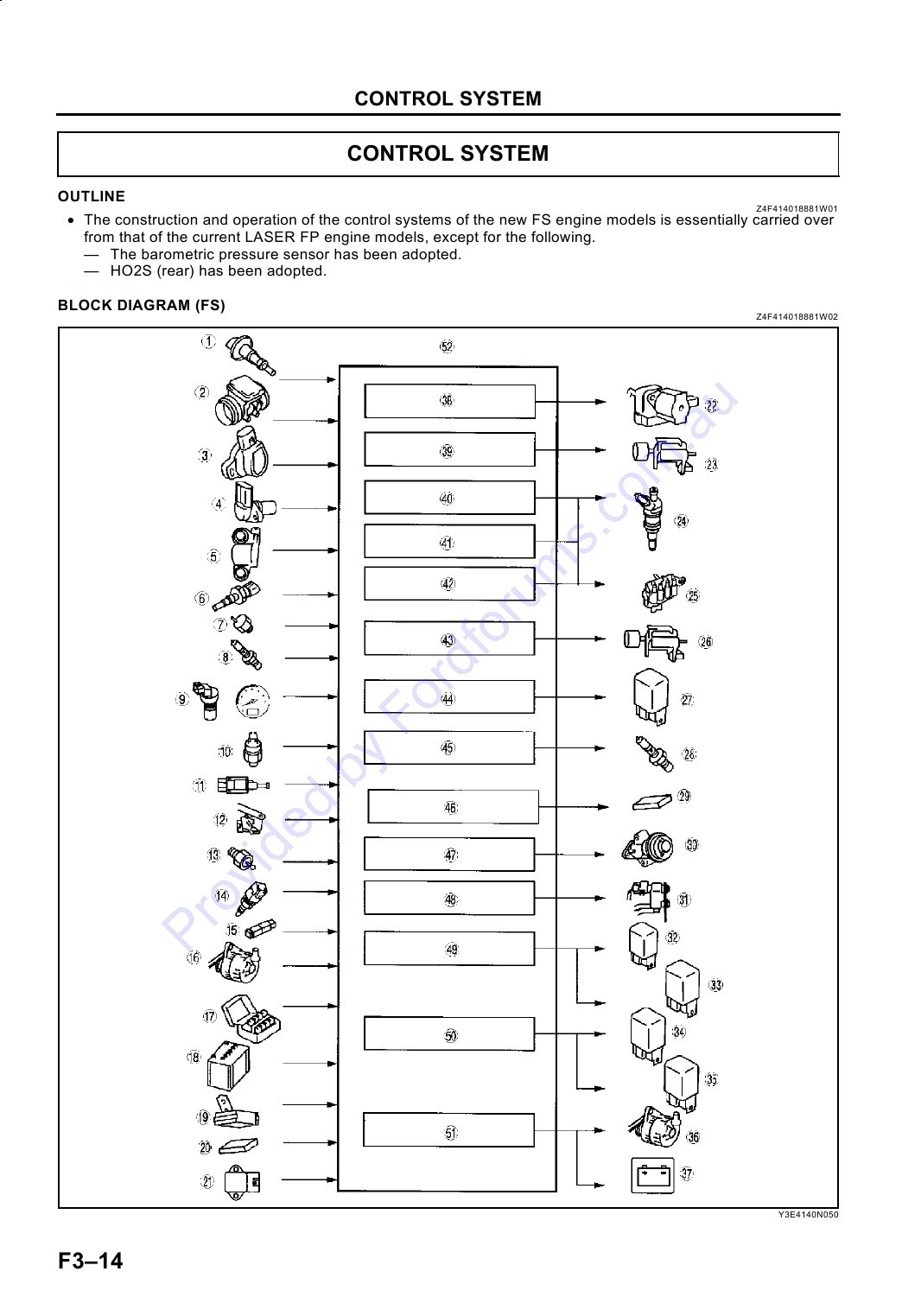

Z4F414018881W01

· The construction and operation of the control systems of the new FS engine models is essentially carried over

from that of the current LASER FP engine models, except for the following.

-- The barometric pressure sensor has been adopted.

-- HO2S (rear) has been adopted.

End Of Sie

BLOCK DIAGRAM (FS)

Z4F414018881W02

Y3E4140N050

.

F314

CONTROL SYSTEM

1

IAT sensor

27

Fuel pump relay

2

MAF sensor

28

HO2S heater (front and rear)

3

TP sensor

29

ABS/TCS HU/CM or DSC

4

CMP sensor

30

EGR valve

5

CKP sensor

31

Purge solenoid valve

6

ECT sensor

32

A/C relay (with A/C)

7

Knock sensor

33

Condenser fan relay (MTX)

8

HO2S (front and rear)

34

Cooling fan relay

9

VSS

35

Condenser fan relay (ATX)

10

Clutch switch (MTX)

36

Generator (terminal D: field coil control)

11

Neutral switch (MTX)

Generator warning light (integrated with instrument

37

cluster)

12

TR switch (ATX)

38

IAC (idle air control) system

13

PSP switch

39

VICS (variable inertia charging system)

14

Brake switch

40

Fuel injection control

A/C switch, refrigerant pressure switch (high, low

15

41

Immobilizer system

pressure) (with A/C)

42

ESA (electronic spark advance) control

16

Generator (terminal P: output voltage)

F3

43

PRC (pressure regulator control)

17

DLC (terminal TEN)

44

Fuel pump control

18

Battery

45

HO2S control

19

Immobilizer unit

46

Traction control

20

ABS/TCS HU/CM or DSC

47

EGR control

21

Barometric Pressure sensor

48

Purge control

22

IAC valve

49

A/C cut-off control

23

VICS solenoid valve

50

Electrical fan control

24

Fuel injectors

51

Generator control

25

Ignition coil

52

PCM

26

PRC solenoid valve

End Of Sie

F315

CONTROL SYSTEM

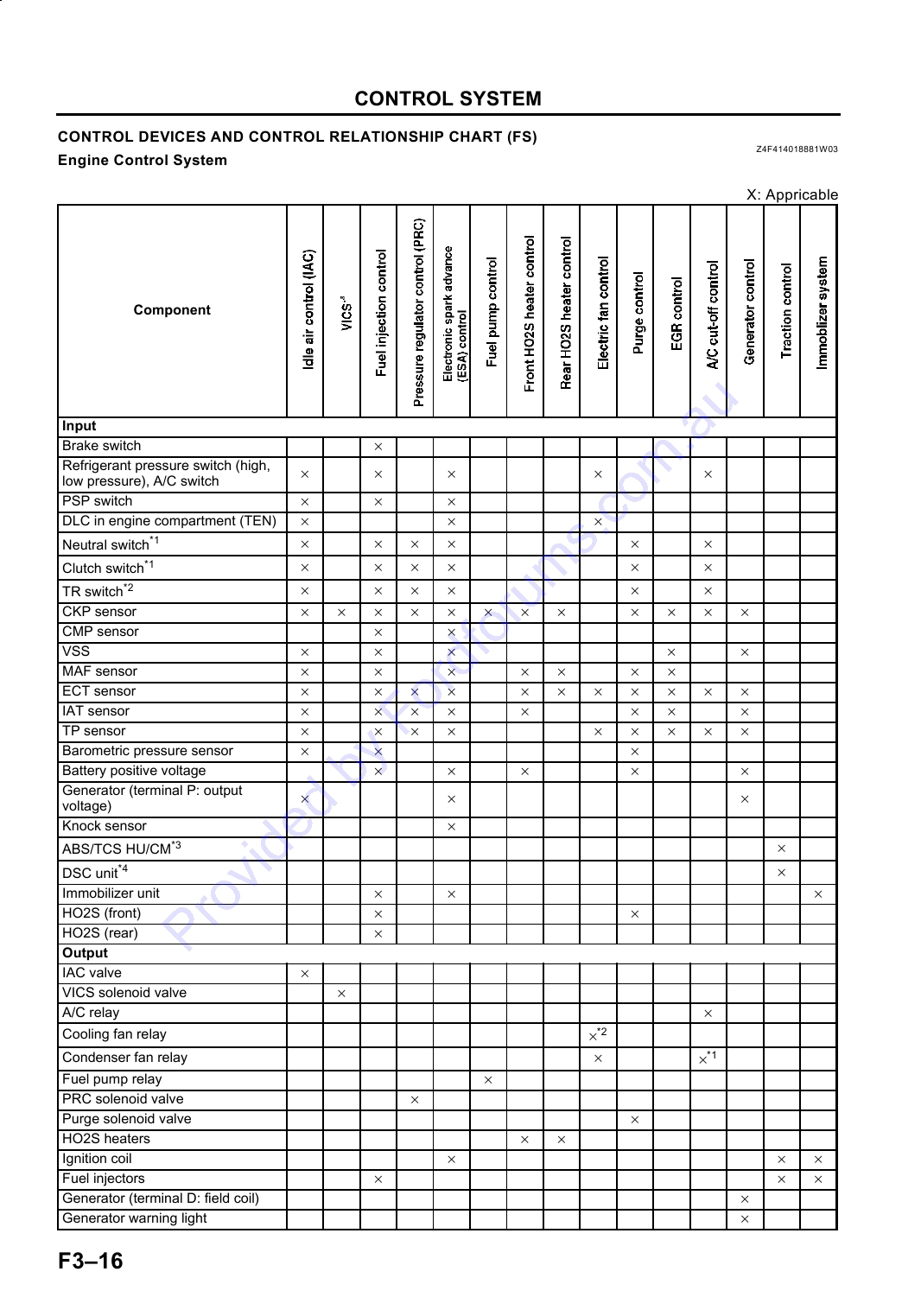

CONTROL DEVICES AND CONTROL RELATIONSHIP CHART (FS)

Z4F414018881W03

Engine Control System

X: Appricable

Component

Input

×

Brake switch

Refrigerant pressure switch (high,

×

×

×

×

×

low pressure), A/C switch

×

×

×

PSP switch

×

×

×

DLC in engine compartment (TEN)

×

×

×

×

×

×

Neutral switch*1

×

×

×

×

×

×

Clutch switch*1

×

×

×

×

×

×

TR switch*2

×

×

×

×

×

×

×

×

×

×

×

×

CKP sensor

×

×

CMP sensor

×

×

×

×

×

VSS

×

×

×

×

×

×

×

MAF sensor

×

×

×

×

×

×

×

×

×

×

×

ECT sensor

×

×

×

×

×

×

×

×

IAT sensor

×

×

×

×

×

×

×

×

×

TP sensor

×

×

×

Barometric pressure sensor

×

×

×

×

×

Battery positive voltage

Generator (terminal P: output

×

×

×

voltage)

×

Knock sensor

×

ABS/TCS HU/CM*3

×

DSC unit*4

×

×

×

Immobilizer unit

×

×

HO2S (front)

×

HO2S (rear)

Output

×

IAC valve

×

VICS solenoid valve

×

A/C relay

×*2

Cooling fan relay

×

×*1

Condenser fan relay

×

Fuel pump relay

×

PRC solenoid valve

×

Purge solenoid valve

×

×

HO2S heaters

×

×

×

Ignition coil

×

×

×

Fuel injectors

×

Generator (terminal D: field coil)

×

Generator warning light

F316

CONTROL SYSTEM

Component

×

ABS/TCS HU/CM*3

×

DSC unit*4

*1

: For MTX model

*2

: For ATX model

*3

: With TCS

*4

: With DSC

F3

Monitoring System

X: Appricable

Component

Input

×

×

×

×

×

CKP sensor

×

×

×

×

×

CMP sensor

×

×

×

×

VSS

×

×

×

×

×

MAF sensor

×

×

×

×

×

ECT sensor

×

×

×

×

IAT sensor

×

×

×

×

TP sensor

×

×

×

HO2S (rear)

×

×

×

×

HO2S (front)

Output

×

×

×

×

×

DLC-2 in drivers compartment (Terminal KLN)

×

×

Purge solenoid valve

×

Fuel injectors

End Of Sie

F317

CONTROL SYSTEM

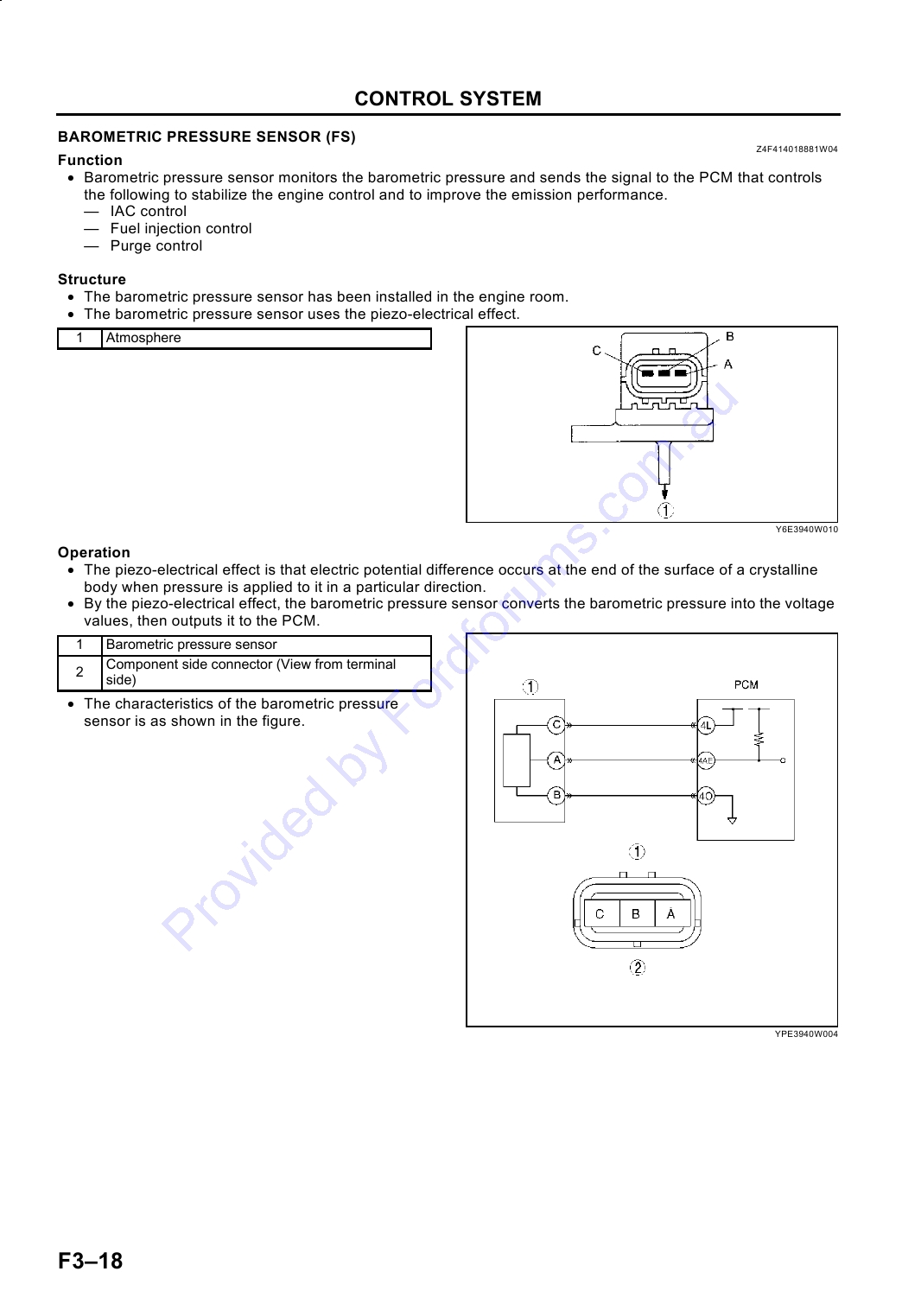

BAROMETRIC PRESSURE SENSOR (FS)

Z4F414018881W04

Function

· Barometric pressure sensor monitors the barometric pressure and sends the signal to the PCM that controls

the following to stabilize the engine control and to improve the emission performance.

-- IAC control

-- Fuel injection control

-- Purge control

Structure

· The barometric pressure sensor has been installed in the engine room.

· The barometric pressure sensor uses the piezo-electrical effect.

.

1

Atmosphere

Y6E3940W010

Operation

· The piezo-electrical effect is that electric potential difference occurs at the end of the surface of a crystalline

body when pressure is applied to it in a particular direction.

· By the piezo-electrical effect, the barometric pressure sensor converts the barometric pressure into the voltage

values, then outputs it to the PCM.

.

1

Barometric pressure sensor

Component side connector (View from terminal

2

side)

· The characteristics of the barometric pressure

sensor is as shown in the figure.

YPE3940W004

F318

CONTROL SYSTEM

.

1

Output voltage

2

Atmospheric pressure

Y6E3940W003

End Of Sie

REAR HEATED OXYGEN SENSOR (HO2S) (FS)

Z4F414018861W01

Function

· Rear HO2S monitors the condition of the WU-TWC.

Structure

· Rear HO2S is installed between the WU-TWC and the TWC (downstream of the WU-TWC).

· Rear HO2S has the heater for the stable signal detection.

F3

Operation

Rear HO2S

· The characteristic of the HO2S is as shown in the

figure. Its electromotive force changes depending

on the amount of oxygen.

.

1

Electromotive force

2

Air/fuel ratio

3

High

4

Low

5

Rich

6

Lean

· Rear HO2S is used for monitoring the WU-TWC

Y6E3940W004

efficiency based on oxygen storage capacity.

· If the WU-TWC has high oxygen storage, the rear

HO2S switching frequency slows compared to

that of the front HO2S.

.

1

Voltage

2

Time

3

Low oxygen

4

High oxygen

Y6E3940W005

· If the WU-TWC deteriorates and oxygen storage

capability declines, the rear HO2S frequency

switches more rapidly.

.

1

Voltage

2

Time

3

Low oxygen

4

High oxygen

Y6E3940W006

F319

CONTROL SYSTEM

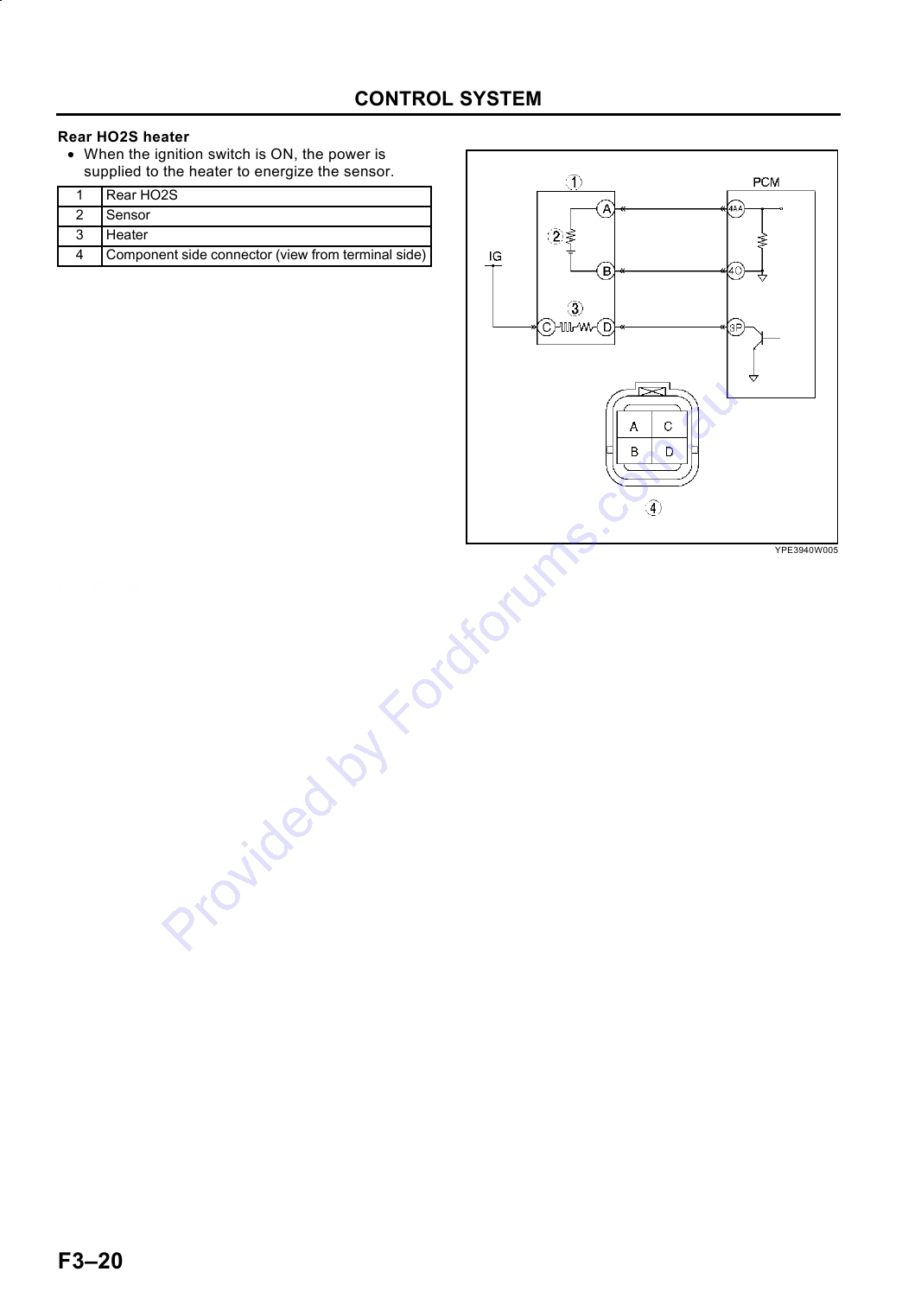

Rear HO2S heater

· When the ignition switch is ON, the power is

supplied to the heater to energize the sensor.

.

1

Rear HO2S

2

Sensor

3

Heater

4

Component side connector (view from terminal side)

YPE3940W005

End Of Sie

F320

ON-BOARD DIAGNOSTIC

ON-BOARD DIAGNOSTIC

OUTLINE

Z4F417018881W01

· The construction and operation of the control systems of the new FS engine models is essentially carried over

from that of the previous LASER FP engine models, except for the following. (See LASER Training Manual

F328-10-98K.)

-- DTCs PID monitoring items, and simulation items have been added to match the EURO-OBD regulations

without malfunction indicator (MI). For the detailed information of the EURO-OBD regulations, refer to the

"OBD Training Manual (3345-1*-00B)."

End Of Sie

DIAGNOSTIC TEST MODE (FS)

Z4F417018881W02

· The following diagnostic test modes have been available to match the EURO-OBD regulations.

Diagnostic test mode

Item

Mode 01

Sending diagnostic data (PID data monitor/on-board system readiness test)

Mode 02

Sending freeze frame data

Mode 03

Sending emission-related malfunction code (diagnostic trouble code: DTC)

F3

Mode 04

Clearing/resetting emission-related malfunction information

Mode 05

Sending oxygen sensor monitor test results

Mode 06

Sending intermittent monitoring system test results (diagnostic monitoring test result: DMTR)

Mode 07

Sending continuous monitoring system test results (pending code)

Sending Diagnostic Data (Mode 01)

PID data monitor

· The PID monitoring items are shown in the table.

PID data monitor table

Monitor item

Full names

Condition/unit

DTC_CNT

Diagnostic trouble code counter

°C, °F

ECT

Engine coolant temperature

FUELSYS

Fuel system loop status

Refer to table below.

°C, °F

IAT

Intake air temperature

LOAD

Engine load calculated value

%

LONGFT1

Long fuel trim

%

MAF

Mass air flow

g/s, lb/m

MIL

Malfunction indicator

ON/OFF

MIL DIS

Distance travelled while MI is activated

km, miles

O2S11

HO2S (Heated oxygen sensor) (Front)

V

O2S12

HO2S (Heated oxygen sensor) (Rear)

V

RPM

Engine speed

rpm

SHRFT1

Short fuel trim

%

SPARKADV

Spark advance

BTDC

TP

Throttle position

%

VSS

Vehicle speed

km/h, mph

Meaning of FUELSYS

Display

Meaning

-NA-

Not applicable

OL

Feedback stops: Engine coolant temperature is lower than the determined feedback zone.

CL

Feedback operating: HO2S being used for feedback is okay.

OLDrive

Feedback stops: Open loop due to driving condition.

OLFault

Feedback stops: Open loop due to detected system fault.

CLFault

Feedback operating: Malfunction occurred in HO2S (rear) system.

F321

ON-BOARD DIAGNOSTIC

On-board system readiness test

· The items supported by the on-board system readiness test are shown below.

Continuous monitoring system

-- Misfire monitoring

-- Fuel system monitoring

-- Comprehensive component monitoring (CCM)

Intermittent monitoring system

-- Catalyst monitoring

-- HO2S monitoring

-- HO2S heater monitoring

Sending Freeze Frame Data (FFD) (Mode 02)

· The FFDs are shown in the table.

FFD monitor table

Monitor item

Full names

Condition/unit

Diagnostic trouble code (DTC)

°C, °F

ECT

Engine coolant temperature

FUELSYS

Fuel system loop status

OPEN: NONF/B, CLOSE: F/B

LOAD

Engine load calculated value

%

LONGFT1

Long fuel trim

%

RPM

Engine speed

rpm

SHRFT1

Short fuel trim

%

VSS

Vehicle speed

km/h, mph

Sending Emission-related Malfunction code (DTC)

· The DTCs are shown in the table.

DTC table

×: Applied

Hold

Memory

DTC

Condition

indicator

DC

Monitor item

function

light

×

P0031

HO2S (front) heater circuit low input

--

2

HO2S heater

×

P0032

HO2S (front) heater circuit high input

--

2

HO2S heater

×

P0037

HO2S (rear) heater circuit low input

--

2

HO2S heater

×

P0038

HO2S (rear) heater circuit high input

--

2

HO2S heater

×

P0102

MAF circuit low input

--

1

CCM

×

P0103

MAF circuit high input

--

1

CCM

×

P0107

BARO circuit low input

--

1

CCM

×

P0108

BARO circuit high input

--

1

CCM

×

P0111

IAT circuit performance problem

--

2

CCM

×

P0112

IAT circuit low input

--

1

CCM

×

P0113

IAT circuit high input

--

1

CCM

×

P0117

ECT circuit low input

--

1

CCM

×

P0118

ECT circuit high input

--

1

CCM

×

P0122

TP circuit low input

Flashes

1

CCM

×

P0123

TP circuit high input

Flashes

1

CCM

×

P0125

Excessive time to enter closed loop fuel control

--

2

CCM

×

P0130

HO2S (front) circuit malfunction

--

2

HO2S

×

P0134

HO2S (front) circuit no activity detected

--

2

CCM

×

P0138

HO2S (rear) circuit high voltage

--

2

CCM

×

P0140

HO2S (rear) circuit no activity detected

--

2

CCM

×

P0171

Fuel trim system too lean

--

2

Fuel

×

P0172

Fuel trim system too rich

--

2

Fuel

×

P0300

Random misfire detection

--

1 or 2

Misfire

×

P0301

Cylinder No.1 misfire detected

--

1 or 2

Misfire

×

P0302

Cylinder No.2 misfire detected

--

1 or 2

Misfire

×

P0303

Cylinder No.3 misfire detected

--

1 or 2

Misfire

×

P0304

Cylinder No.4 misfire detected

--

1 or 2

Misfire

×

P0327

Knock sensor circuit low input

--

1

CCM

F322

ON-BOARD DIAGNOSTIC

Hold

Memory

DTC

Condition

indicator

DC

Monitor item

function

light

×

P0328

Knock sensor circuit high input

--

1

CCM

×

P0335

CKP sensor circuit malfunction

--

1

CCM

×

P0421

Warm-up catalyst system efficiency below threshold

--

2

Catalyst

Evaporative emission solenoid system purge control valve

×

P0443

--

2

CCM

circuit malfunction

×

P0500

Vehicle speed sensor (VSS) circuit malfunction (MTX)

--

2

CCM

×

P0506

Idle control system RPM lower than expected

--

2

CCM

×

P0507

Idle control system RPM higher than expected

--

2

CCM

×

P0550

PSP switch circuit malfunction

--

2

CCM

×

P0605

PCM read only memory (ROM) test error

--

1

Other

×

P0703

Brake switch input malfunction

--

2

CCM

×

P0704

Clutch switch circuit malfunction (MTX)

--

2

CCM

×

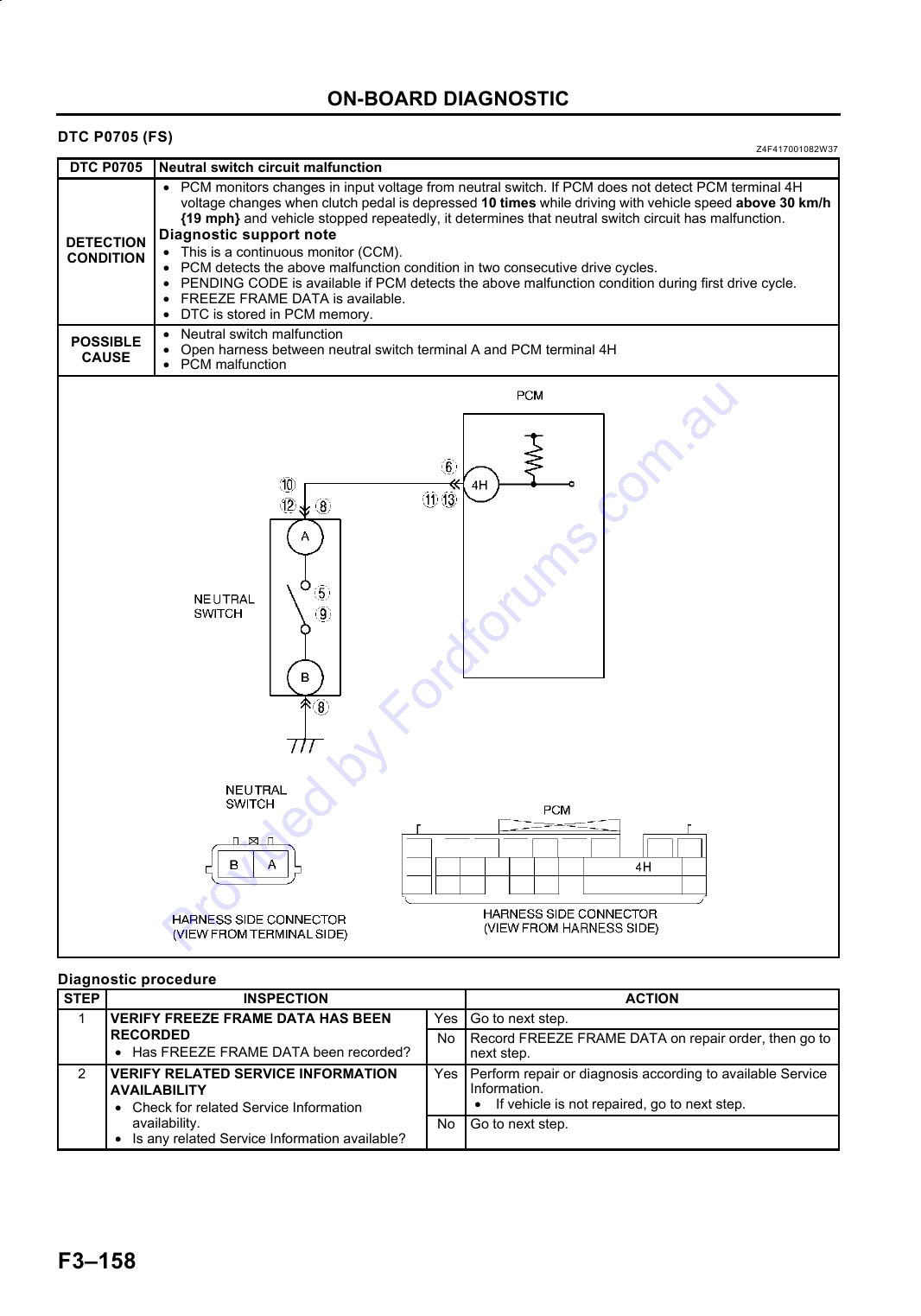

P0705

Neutral switch circuit malfunction (MTX)

--

2

CCM

MAF sensor value inconsistent with TP sensor (lower than

×

P1102

--

2

CCM

expected)

F3

MAF sensor value inconsistent with engine speed (greater

×

P1103

--

2

CCM

than expected)

×

P1122

Throttle position stuck closed (lower than expected)

--

2

CCM

×

P1123

Throttle position stuck open (higher than expected)

--

2

CCM

×

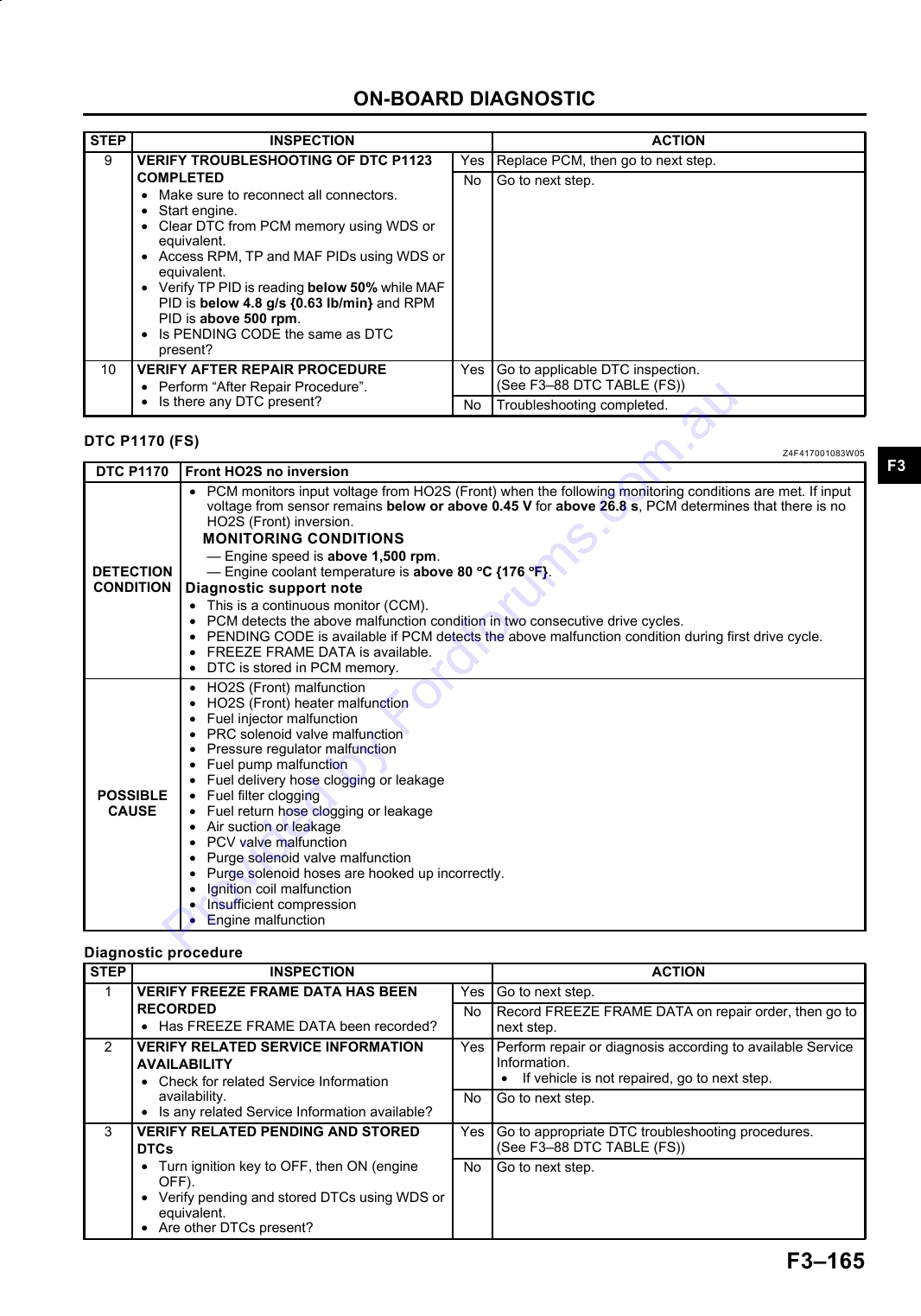

P1170

HO2S (front) no inversion

--

2

CCM

P1250

Pressure regulator control (PRC) valve circuit malfunction

--

1

CCM

--

×

P1345

CMP sensor circuit malfunction

--

1

CCM

×

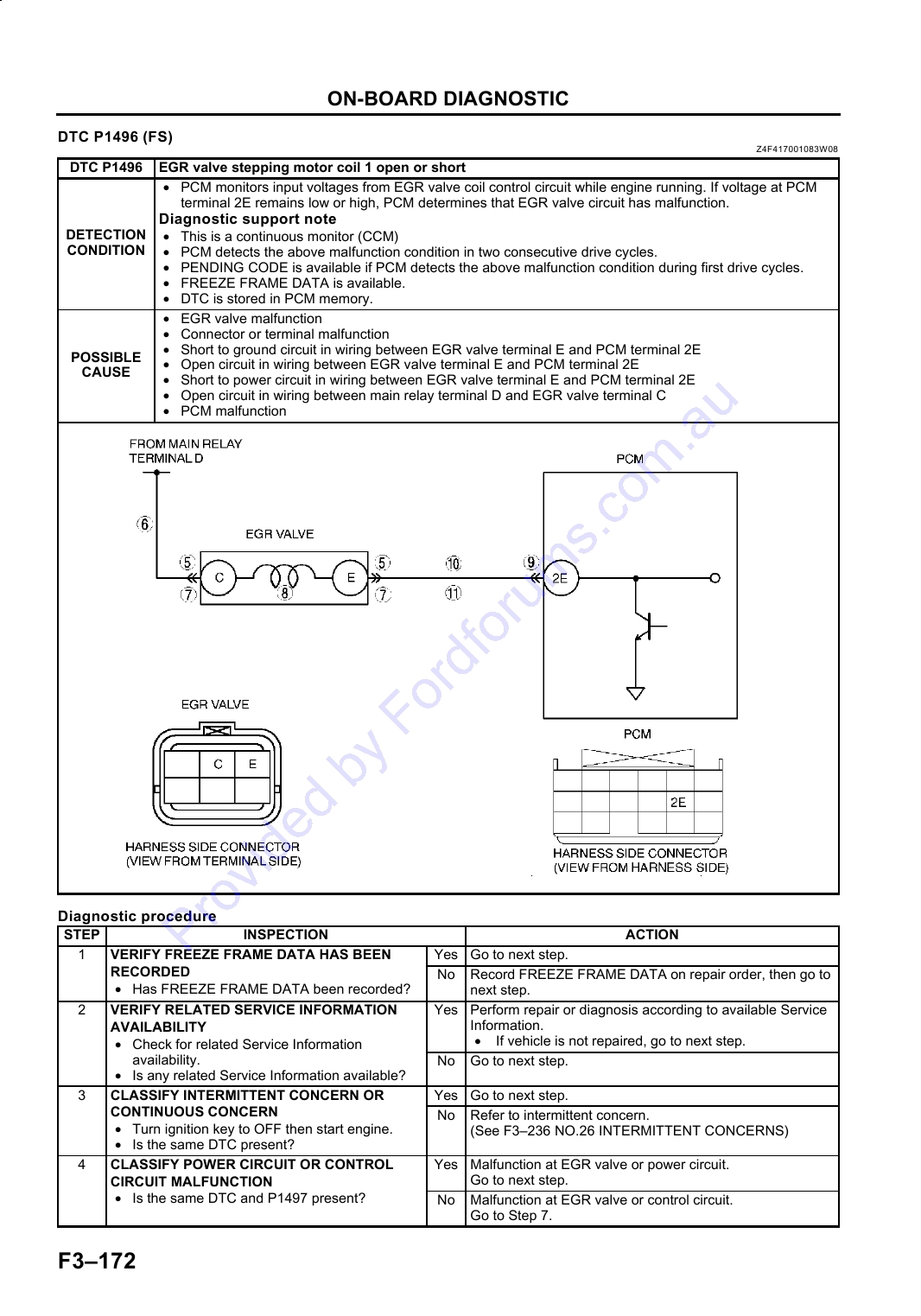

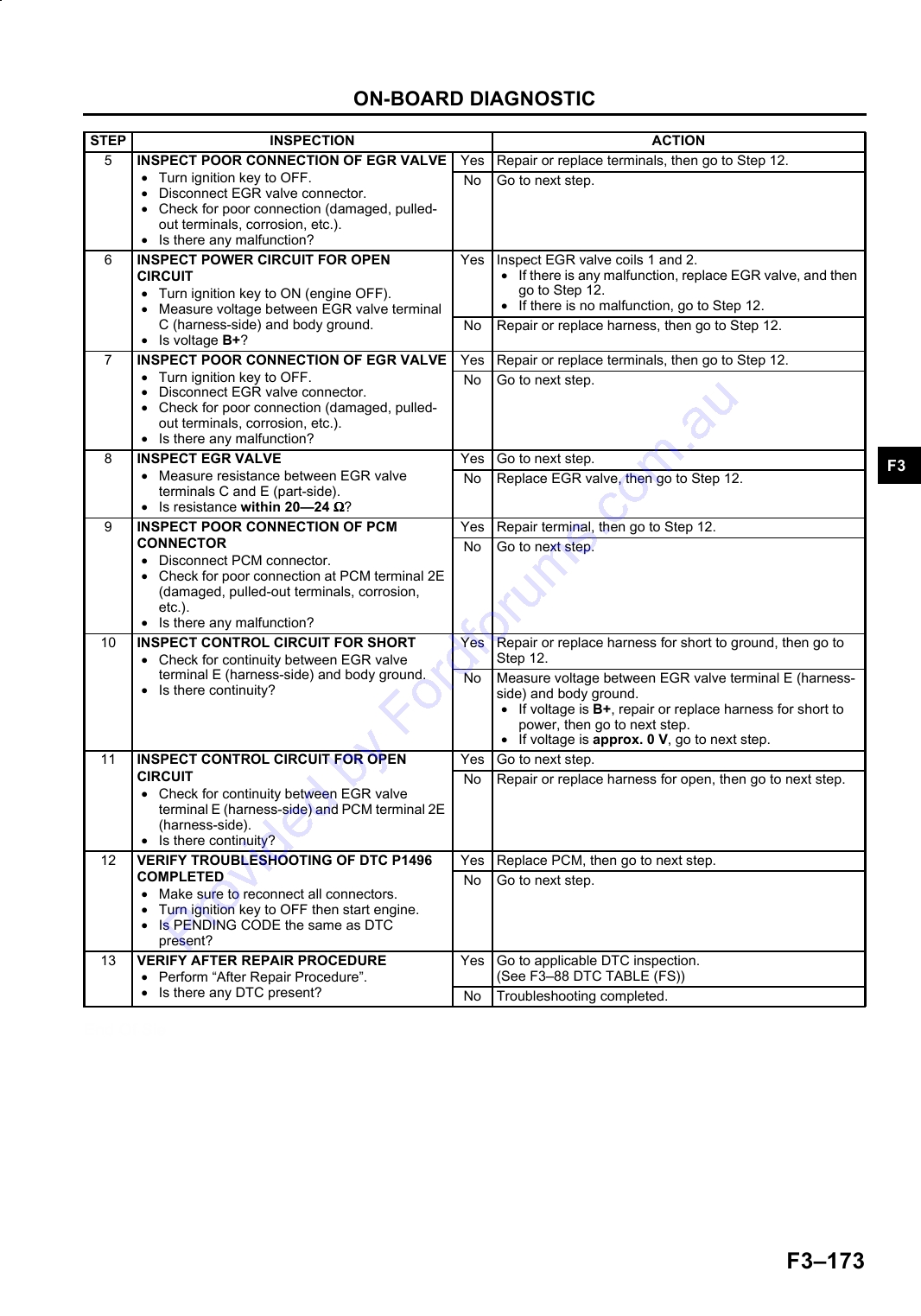

P1496

EGR valve stepping motor coil 1 open or short

--

2

CCM

×

P1497

EGR valve stepping motor coil 2 open or short

--

2

CCM

×

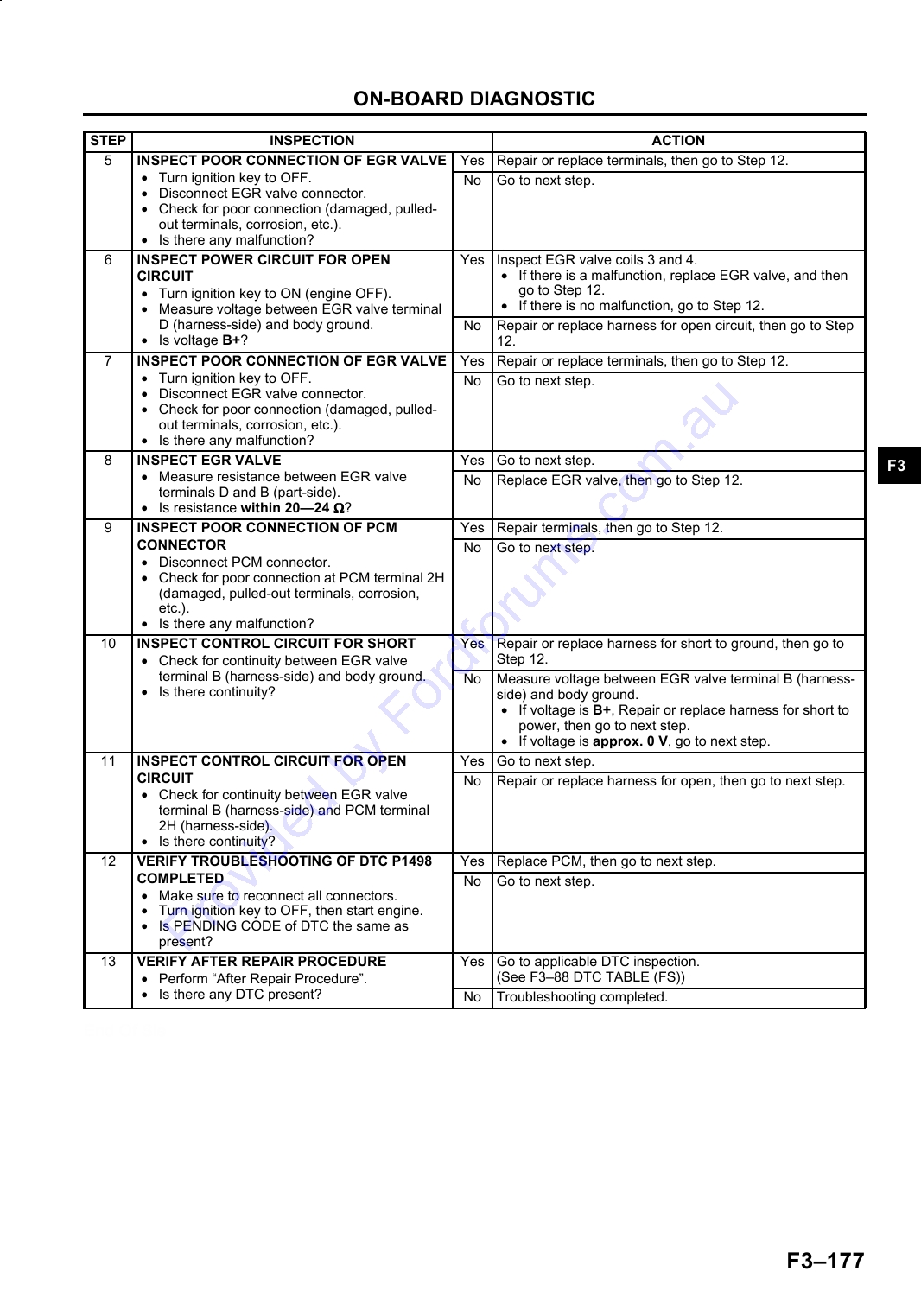

P1498

EGR valve stepping motor coil 3 open or short

--

2

CCM

×

P1499

EGR valve stepping motor coil 4 open or short

--

2

CCM

×

P1504

IAC valve circuit malfunction

--

1

CCM

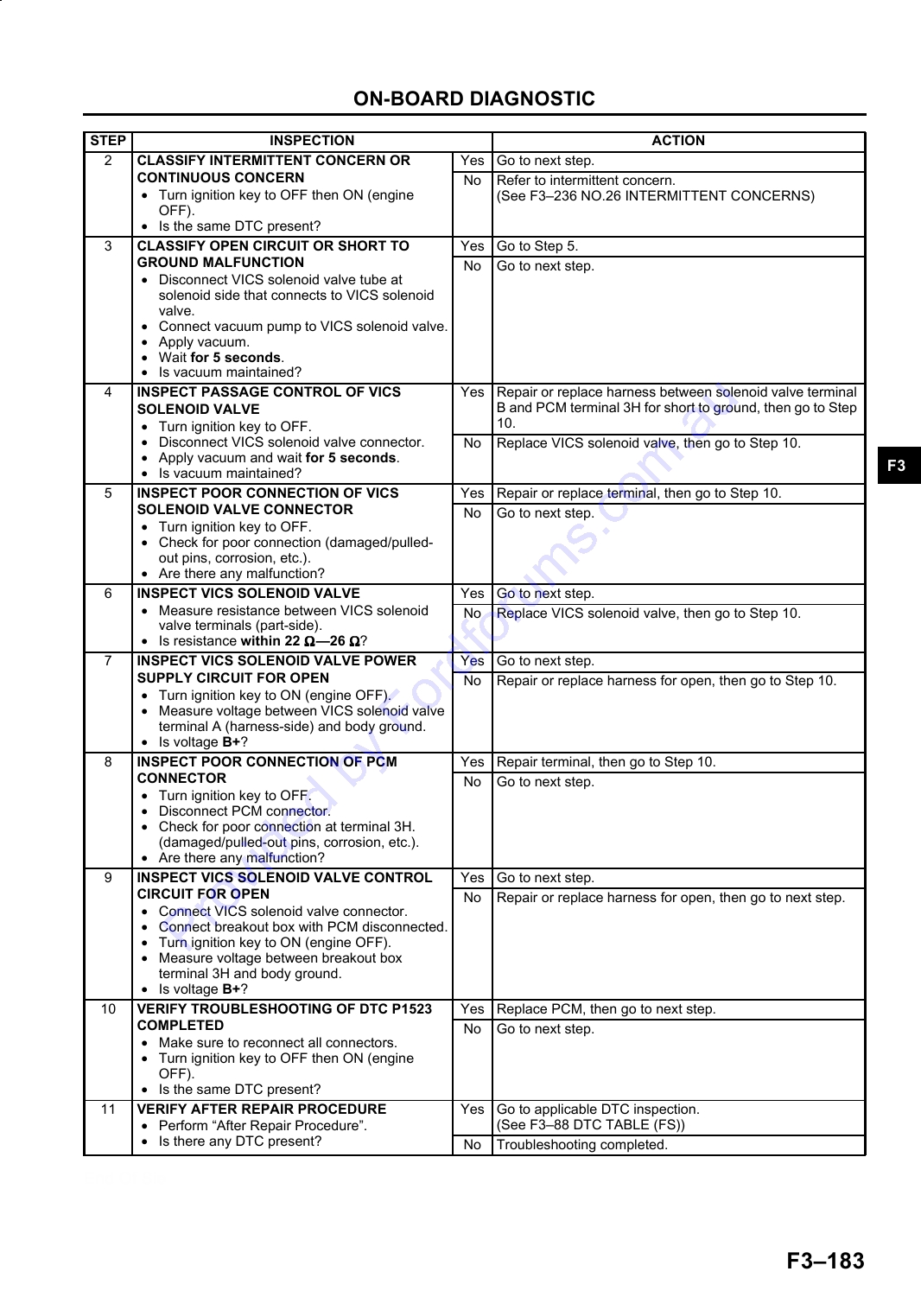

P1523

VICS solenoid valve circuit malfunction

--

1

Other

--

×

P1562

PCM +BB voltage low

--

1

CCM

×

P1602

Immobilizer unit-PCM communication error

--

--

Other

×

P1603

Key ID number unregistered in PCM

--

--

Other

×

P1604

Code word unregistered in PCM

--

--

Other

P1608

PCM internal circuit mulfunction

--

1

Other

--

×

P1621

Code words do not match after engine cranking

--

--

Other

×

P1622

Key ID number mismatch

--

--

Other

×

P1623

Cord word or key ID number read/write error in PCM

--

--

Other

×

P1624

Immobilizer system communication counter=0

--

--

Other

×

P1627

PCM/TCS line-communication error

--

1

Other

×

P1631

Generator output voltage signal no electricity

--

1

Other

×

P1633

Battery overcharge

--

1

Other

×

P1634

Generator terminal B circuit open

--

1

Other

Sending Intermittent Monitoring System Test Results (Mode 06)

· The items supported by the sending intermittent monitoring system are shown in the table.

TEST ID

Description

Related system

10:01:11

HO2S (front) inversion cycles

10:02:11

HO2S (front) lean-to-rich response time

10:03:11

HO2S (front) rich-to-lean response time

10:04:01

HO2S (front) rich/lean inversion voltage

HO2S

10:04:02

HO2S (rear) inversion voltage

10:05:01

HO2S (front) lean threshold voltage

10:06:01

HO2S (front) rich threshold voltage

10:11:11

HO2S (front and rear) switching time ratio

TWC

F323

ON-BOARD DIAGNOSTIC

End Of Sie

DTC (FS)

Z4F417018881W03

· The DTCs shown below have been added, or changed for the detection logic or condition.

Heated Oxygen Sensor (HO2S) Heater

HO2S heater (front) circuit low input (P0031)

· PCM terminal (3J) voltage is low when HO2S heater (front) condition is OFF.

HO2S heater (front) circuit high input (P0032)

· PCM terminal (3J) voltage is high when HO2S heater (front) condition is ON.

HO2S heater (rear) circuit low input (P0037)

· PCM terminal (3P) voltage is low when HO2S heater (rear) condition is OFF.

HO2S heater (rear) circuit high input (P0038)

· PCM terminal (3P) voltage is high when HO2S heater (rear) condition is ON.

Barometric Pressure Sensor

BARO circuit low input (P0107)

· Input voltage from barometric pressure sensor is below 1.99 V while engine running.

BARO circuit high input (P0108)

· Input voltage from barometric pressure sensor is above 4.43 V while engine running.

Intake Air Temperature (IAT) Sensor

IAT circuit performance problem (P0111)

· Intake air temperature is higher than engine coolant temperature by 40°C {104°F} while engine running.

Engine Coolant Temperature (ECT) Sensor

Excessive time to enter closed loop fuel control (P0125)

· ECT does not rise above specified temperature after engine is started and a certain period of time has passed.

Heated Oxygen Sensor (HO2S) (front)

HO2S (front) circuit malfunction (P0130)

· HO2S (front) sends any of the following HO2S (front) signals while driving under the following conditions:

Conditions

-- Engine speed is 1,410--4,000 rpm.

-- Calculated load is 15--59% [MTX] 18--59% [ATX] (depending on engine speed).

-- ECT is above 10°C {14°F}.

-- Vehicle speed is over 3.8 km/h {2.4 mph}.

MTX

ATX

A

More than 0.51 s

More than 0.53 s

B

More than 0.56 s

More than 0.42 s

Y6E3970W001

.

1

Oxygen sensor output signal

4

Oxygen sensor lean-to-rich response time

2

Rich

5

Oxygen sensor rich-to-lean response time

3

Lean

F324

ON-BOARD DIAGNOSTIC

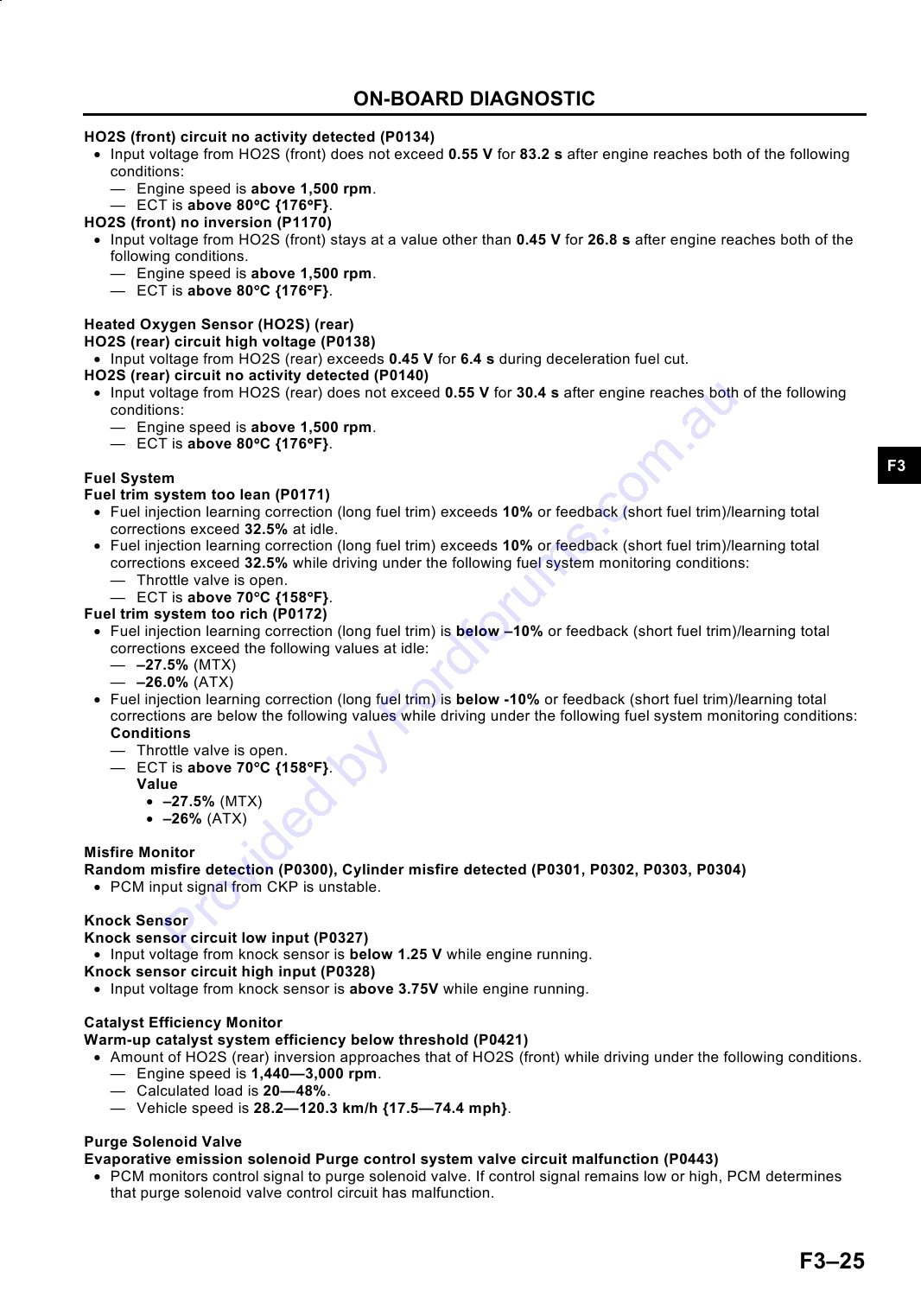

HO2S (front) circuit no activity detected (P0134)

· Input voltage from HO2S (front) does not exceed 0.55 V for 83.2 s after engine reaches both of the following

conditions:

-- Engine speed is above 1,500 rpm.

-- ECT is above 80°C {176°F}.

HO2S (front) no inversion (P1170)

· Input voltage from HO2S (front) stays at a value other than 0.45 V for 26.8 s after engine reaches both of the

following conditions.

-- Engine speed is above 1,500 rpm.

-- ECT is above 80°C {176°F}.

Heated Oxygen Sensor (HO2S) (rear)

HO2S (rear) circuit high voltage (P0138)

· Input voltage from HO2S (rear) exceeds 0.45 V for 6.4 s during deceleration fuel cut.

HO2S (rear) circuit no activity detected (P0140)

· Input voltage from HO2S (rear) does not exceed 0.55 V for 30.4 s after engine reaches both of the following

conditions:

-- Engine speed is above 1,500 rpm.

-- ECT is above 80°C {176°F}.

F3

Fuel System

Fuel trim system too lean (P0171)

· Fuel injection learning correction (long fuel trim) exceeds 10% or feedback (short fuel trim)/learning total

corrections exceed 32.5% at idle.

· Fuel injection learning correction (long fuel trim) exceeds 10% or feedback (short fuel trim)/learning total

corrections exceed 32.5% while driving under the following fuel system monitoring conditions:

-- Throttle valve is open.

-- ECT is above 70°C {158°F}.

Fuel trim system too rich (P0172)

· Fuel injection learning correction (long fuel trim) is below 10% or feedback (short fuel trim)/learning total

corrections exceed the following values at idle:

-- 27.5% (MTX)

-- 26.0% (ATX)

· Fuel injection learning correction (long fuel trim) is below -10% or feedback (short fuel trim)/learning total

corrections are below the following values while driving under the following fuel system monitoring conditions:

Conditions

-- Throttle valve is open.

-- ECT is above 70°C {158°F}.

Value

· 27.5% (MTX)

· 26% (ATX)

Misfire Monitor

Random misfire detection (P0300), Cylinder misfire detected (P0301, P0302, P0303, P0304)

· PCM input signal from CKP is unstable.

Knock Sensor

Knock sensor circuit low input (P0327)

· Input voltage from knock sensor is below 1.25 V while engine running.

Knock sensor circuit high input (P0328)

· Input voltage from knock sensor is above 3.75V while engine running.

Catalyst Efficiency Monitor

Warm-up catalyst system efficiency below threshold (P0421)

· Amount of HO2S (rear) inversion approaches that of HO2S (front) while driving under the following conditions.

-- Engine speed is 1,440--3,000 rpm.

-- Calculated load is 20--48%.

-- Vehicle speed is 28.2--120.3 km/h {17.5--74.4 mph}.

Purge Solenoid Valve

Evaporative emission solenoid Purge control system valve circuit malfunction (P0443)

· PCM monitors control signal to purge solenoid valve. If control signal remains low or high, PCM determines

that purge solenoid valve control circuit has malfunction.

F325

ON-BOARD DIAGNOSTIC

Vehicle Speed Sensor (VSS)

VSS circuit malfunction (P0500) (MTX)

· Vehicle speed signal does not input after following conditions are met.

-- Gear is in position other than neutral.

-- Changing deficiency is above 0.4.

-- Engine speed is 2,000 rpm or above.

Idle Air Control (IAC) Valve

Idle control system RPM lower than expected (P0506)

· The actual idle speed is lower than expected by 100 rpm for 14.1 s, when the brake pedal is depressed (brake

switch is ON) and the steering wheel is held straight ahead (PSP switch is OFF).

Idle control system RPM higher than expected (P0507)

· The actual idle speed is higher than expected by 200 rpm for 14.1 s, when the brake pedal is depressed (brake

switch is ON) and the steering wheel is held straight ahead (PSP switch is OFF).

Note

· If atmospheric pressure is less than 542 mmHg {21.3 inHg} or intake air temperature is below 10°C

{14°F}, PCM cancels diagnosis of P0506 and P0507.

Power Steering Pressure (PSP) Switch

PSP switch circuit malfunction (P0550)

· PSP signal stays ON for 1 min, vehicle speed is above 60 km/h {37 mph}, and ECT is above 60°C {140°F}.

Brake Switch

Brake switch input malfunction (P0703)

· Brake switch does not turn on/off after vehicle has been accelerated and decelerated between 0--30 km/h

{0--19 mph} repeatedly (more than 8 times).

Clutch Switch (MTX)

Clutch switch input circuit malfunction (P0704)

· Clutch switch does not turn on/off after vehicle has been accelerated and decelerated between 0--30 km/h

{0--19 mph} repeatedly (more than 8 times).

Neutral Switch (MTX)

Neutral switch circuit malfunction (P0705)

· Neutral switch does not turn on/off and clutch switch turns on/off 10 times at vehicle speed above 30 km/h {19

mph}.

Mass Air Flow (MAF) Sensor

MAF sensor value inconsistent with TP sensor (lower than expected) (P1102)

· Mass intake air flow amount is below 4.8 g/s {0.63 lb/min}, throttle opening angle is above 50% and engine is

running.

MAF sensor value inconsistent with engine speed (greater than expected) (P1103)

· Mass intake air flow amount is above 72.8 g/s {9.63 lb/min} when engine speed is below 2,000 rpm with

engine running and ECT is above 80°C {176°F}.

Throttle Position (TP) Sensor

Throttle position stuck closed (lower than expected) (P1122)

· Throttle opening angle stays below 12.5%, ECT is above 80°C {176°F} and mass intake airflow amount is

above 64.7 g/s {8.56 lb/min}.

Throttle position stuck open (higher than expected) (P1123)

· Throttle opening angle is above 50% when engine speed is above 500 rpm and mass intake airflow amount is

below 4.8 g/s {0.63 lb/min}.

PCM

PCM +BB voltage low (P1562)

· Power supply terminal (4AG) is below 2.5V for 2 s.

EGR Valve

EGR valve stepping motor coil open or short (P1496, P1497, P1498, P1499)

· PCM monitors control signals to EGR valve stepping motor coils. If control signal remains low or high, PCM

determines that EGR valve control circuit has malfunction.

F326

ON-BOARD DIAGNOSTIC

VICS Solenoid Valve

VICS solenoid valve circuit malfunction (P1523)

· PCM terminal (3H) voltage is low and VICS is OFF or PCM terminal voltage is high and VICS is ON when

ignition switch turned to ON.

End Of Sie

PID/DATA MONITOR AND RECORD

Z4F417018881W04

· The PID/DATA monitoring items for the fuel and emission control systems are as shown in the following table.

PID/DATA Monitor Item

PCM terminal

Monitor item

Monitoring item

Condition/unit

(Display on WDS)

FS

FP

ACCS

A/C relay

ON/OFF

2K

1S

ACSW

Refrigerant pressure switch (high, low pressure)

ON/OFF

4F

1P

ALTF

Generator field coil control duty value

%

3M

1O

ALTT V

Generator output voltage

V

4T

1T

ARPMDES

Target idle speed

rpm

Barometric pressure

kPa, inHg

BARO

4AE

N/A

Barometric pressure signal voltage

V

BOO

Brake switch

ON/OFF

4B

1F

F3

CHRGLP

Generator warning light

ON/OFF

3U

1Q

CPP

Clutch switch

ON/OFF

4I

N/A

°C, °F

Engine coolant temperature

4P

3E

ECT

ECT signal voltage

V

4P

3E

EVAPCP

Purge solenoid valve duty value

%

3C

4L

FAN2

Condenser fan control

ON/OFF

2C

4J

FAN3

Cooling fan control

ON/OFF

2B

1R

Engine coolant temperature recorded when the

°C, °F

FDMECTS

N/A

engine is started before DTC stored

°C, °F

FDMIAT

Intake air temperature when DTC is stored

N/A

Time recorded between engine start and DTC is

FDMTIME

s

N/A

stored

FDMTP

Throttle opening angle when is DTC stored

%

N/A

FDPDTC

Pending code

Engine coolant temperature when PENDING

°C, °F

FDPECT

N/A

CODE is stored

Engine coolant temperature recorded when the

°C, °F

FDPECTS

N/A

engine is started

Fuel system feedback control status when

FDPFS1

OPEN/CLOSE

N/A

PENDING CODE is stored

Intake air temperature when PENDING CODE is

°C, °F

FDPIAT

N/A

stored

Current bank 1 fuel trim adjustment (learning

FDPLFT1

%

N/A

correction value) when PENDING CODE is stored

Calculated engine load when PENDING CODE is

FDPLOAD

%

N/A

stored

FDPRPM

Engine speed when PENDING CODE is stored

rpm

N/A

Current bank 1 fuel trim adjustment when

FDPSFT1

%

N/A

PENDING CODE is stored

Time recorded between engine start and

FDPTIME

s

N/A

PENDING CODE is stored

Throttle opening angle when PENDING CODE is

FDPTP

%

N/A

stored

FDPVS

Vehicle speed when PENDING CODE is stored

km/h, mph

N/A

FP

Fuel pump relay

ON/OFF

2M

4P

FPRC

Pressure regulator control

ON/OFF

2N

4T

2A, 2D,

4W, 4X,

FUELPW1

Fuel injection duration

ms

2G, 2J

4Y, 4Z

HTR11

HO2S (front) control signal in PCM

ON/OFF

3J

1U

HTR12

HO2S (rear) heater control signal in PCM

ON/OFF

3P

N/A

IAC

IAC valve control

%

2P, 2Q

4M, 4O

F327

ON-BOARD DIAGNOSTIC

PCM terminal

Monitor item

Monitoring item

Condition/unit

(Display on WDS)

FS

FP

°C, °F

Intake air temperature

IAT

4N

3B

IAT signal voltage

V

IVC

VICS solenoid valve

ON/OFF

3H

4N

KNOCK1

Knocking retard

Degree

4M

3F

LOAD

Calculated engine load in PCM

%

N/A

Current long fuel trim adjustment (Learning

LONGFT1

%

N/A

correction value in PCM)

Mass air flow amount

g/s, lb/min

N/A

MAF

4X

MAF signal voltage

V

3L

Adaptive memory condition (Readiness Function

MODE1

ON/OFF

--

N/A

Code)

O2S11

HO2S (front) signal voltage

V

4W

3C

O2S12

HO2S (rear) signal voltage

V

4AA

N/A

PNP

Load/no load condition signal

ON/OFF

4H

1V

PSP

PSP switch

ON/OFF

4C

1G

RPM

Engine speed

rpm

3Y, 3Z

3J, 3H

3M, 3N, 3O,

SEGRP

EGR valve stepping motor position

STEP

2E, 2F, 2H, 2I

3P

SHRTFT1

Current short fuel trim adjustment

%

N/A

SPARKADV

Ignition timing

BTC

3F, 3I

4G, 4H

TCS INH

Traction control inhibit signal

ON/OFF

1N

TEST

TEN terminal condition (in DLC)

ON/OFF

4E

1L

TP

TP sensor signal voltage

V

4V

4E

VPWR

Battery positive voltage

V

4AF

1B

1M (MTX)

VSS

Vehicle speed

km/h, mph

3T

3D (ATX)

: Terminal not appricable

N/A:PID not appricable

End Of Sie TEST

SIMULATION

Z4F417018881W05

· The simulation test item for the fuel and emission control systems are as shown in the following table.

Simulation Item Table

PCM terminal

Simulation

Definition

Operation

item

FS

FP

ACCS

A/C relay

ON or OFF

2K

1S

ALTF

Generator field coil

OFF

3M

1O

CHRGLP

Generator warning light

ON or OFF

3U

1Q

Actuated by any duty value

EVAPCP

Purge solenoid valve

3C

4L

(0--100%)

FAN2

Condenser fan relay

ON or OFF

2C

4J

FAN3

Cooling fan relay

ON or OFF

2B

1R

FP

Fuel pump relay

ON or OFF

2M

4P

Actuated by any duty value

FUELPW1

Fuel injection duration

2A, 2D, 2G, 2J

4W, 4X, 4Y, 4Z

(50--+50%)

Actuated by any duty value

IAC

IAC valve

2P, 2Q

4M, 4O

(0--100%)

INJ_1

Fuel injector No.1

OFF

2A

4W

INJ_2

Fuel injector No.2

OFF

2D

4X

INJ_3

Fuel injector No.3

OFF

2G

4Y

INJ_4

Fuel injector No.4

OFF

2J

4Z

IVC

VICS solenoid valve

ON or OFF

3H

4N

FPRC

PRC solenoid valve

ON or OFF

2N

1F

Actuated by any steps

SEGRP

EGR valve

2E, 2F, 2H, 2I

3M, 3N, 3O, 3P

(0--60 step)

End Of Sie

F328

OUTLINE

OUTLINE

SUPPLEMENTAL SERVICE INFORMATION

Z4F410202000W06

· The following changes and/or additions have been

Warm up three way catalytic converter (WU-TWC)

· Inspection procedure has been added.

made since publication of the LASER Repair

PCM

Manual (F328-10-98K) and the LASER Repair

· Inspection procedure has been modified.

Manual Supplement (F164-10-99H).

Intake air temperature (IAT) sensor

Ignition timing

· Inspection procedure has been modified.

Inspection procedure has been modified.

Mass air flow (MAF) sensor

Idle speed

· Inspection procedure has been modified.

Adjustment procedure has been modified.

Throttle position (TP) sensor

Idle-up speed

· Inspection procedure has been modified.

· Inspection procedure has been modified.

· Adjustment procedure has been modified.

Vacuum hose

· Routing diagram has been modified.

Engine coolant temperature (ECT) sensor

· Inspection procedure has been modified.

Idle air control valve

· Inspection procedure has been modified.

Crankshaft position (CKP) sensor

· Inspection procedure has been modified.

VICS solenoid valve

F3

· Inspection procedure has been modified.

Camshaft position (CMP) sensor

· Inspection procedure has been modified.

Fuel pressure

· Inspection procedure has been modified.

Knock sensor

· Inspection procedure has been modified.

Fuel injector

· Removal/installation procedure has been modified.

Barometric pressure sensor

· Inspection procedure has been added.

· Inspection procedure has been modified.

Heated oxgen sensor (HO2S) (front and rear)

Pressure regulator

· Inspection procedure has been modified.

· Removal/installation procedure has been modified.

· Inspection procedure has been modified.

Clutch switch

· Inspection procedure has been modified.

Pressure regulator control (PRC) solenoid valve

· Inspection procedure has been modified.

Neutral switch

· Inspection procedure has been modified.

Fuel pump unit

· Inspection procedure has been modified.

Power steering pressure (PSP) switch

· Inspection procedure has been modified.

Exhaust system

· Removal/installation procedure has been modified.

On-board diagnostic

· Inspection procedure has been modified.

Charcoal canister

· Inspection procedure has been modified.

Troubleshooting

· Inspection procedure has been modified.

Purge solenoid valve

End Of Sie

Inspection procedure has been modified.

EGR valve

· Inspection procedure has been modified.

F329

ENGINE TUNE-UP

ENGINE TUNE-UP

ENGINE TUNE-UP PREPARATION

Z4F410802000W01

Using the SST (WDS or equivalent)

1. Warm up the engine to normal operating temperature.

2. Shift the transaxle into neutral (MTX) or N range (ATX).

3. Turn off all electrical loads.

· Headlight switch

· Blower control switch

· Rear window defroster switch

· A/C switch

4. Verify that the steering wheel is at the straight ahead position.

5. Connect the SSTs (WDS or equivalent) to the DLC (for FP engine)/DLC-2 (for FS engine).

6. Access RPM PID.

7. Wait until the electrical fan stops.

End Of Sie

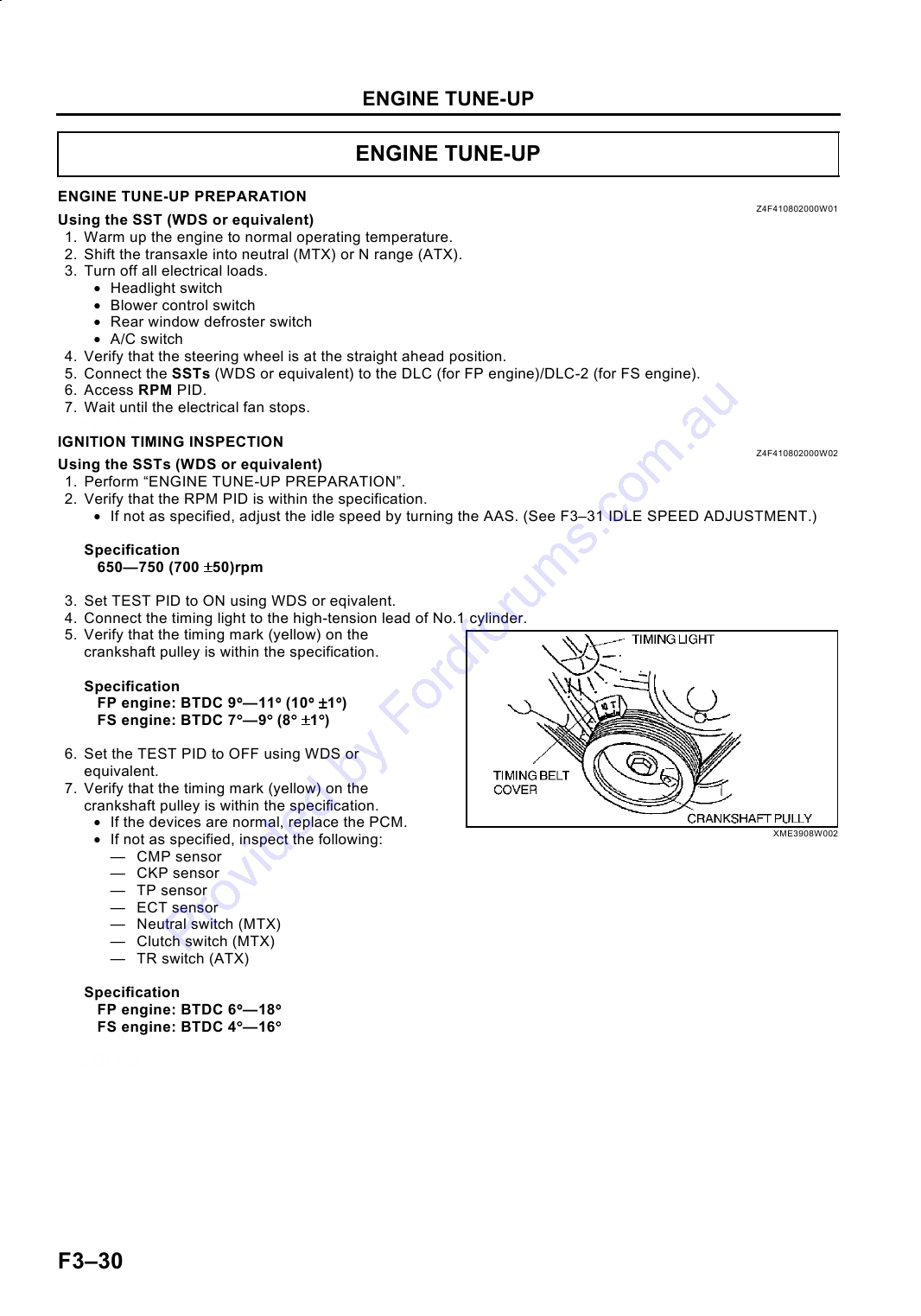

IGNITION TIMING INSPECTION

Z4F410802000W02

Using the SSTs (WDS or equivalent)

1. Perform "ENGINE TUNE-UP PREPARATION".

2. Verify that the RPM PID is within the specification.

· If not as specified, adjust the idle speed by turning the AAS. (See F331 IDLE SPEED ADJUSTMENT.)

Specification

650--750 (700 ±50)rpm

3. Set TEST PID to ON using WDS or eqivalent.

4. Connect the timing light to the high-tension lead of No.1 cylinder.

5. Verify that the timing mark (yellow) on the

crankshaft pulley is within the specification.

Specification

FP engine: BTDC 9°--11° (10° ±1°)

FS engine: BTDC 7°--9° (8° ±1°)

6. Set the TEST PID to OFF using WDS or

equivalent.

7. Verify that the timing mark (yellow) on the

crankshaft pulley is within the specification.

· If the devices are normal, replace the PCM.

· If not as specified, inspect the following:

XME3908W002

-- CMP sensor

-- CKP sensor

-- TP sensor

-- ECT sensor

-- Neutral switch (MTX)

-- Clutch switch (MTX)

-- TR switch (ATX)

Specification

FP engine: BTDC 6°--18°

FS engine: BTDC 4°--16°

End Of Sie

F330

ENGINE TUNE-UP

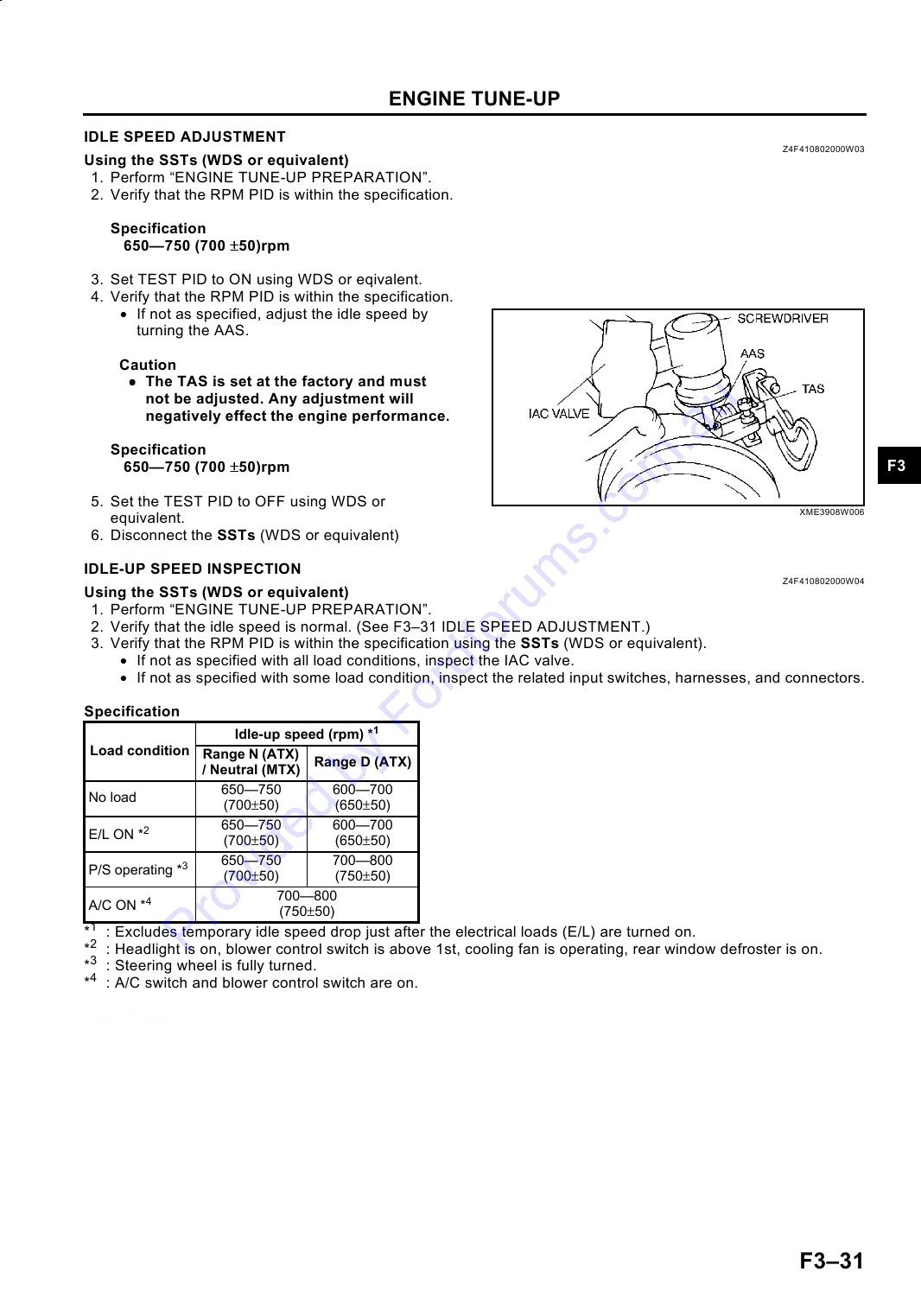

IDLE SPEED ADJUSTMENT

Z4F410802000W03

Using the SSTs (WDS or equivalent)

1. Perform "ENGINE TUNE-UP PREPARATION".

2. Verify that the RPM PID is within the specification.

Specification

650--750 (700 ±50)rpm

3. Set TEST PID to ON using WDS or eqivalent.

4. Verify that the RPM PID is within the specification.

· If not as specified, adjust the idle speed by

turning the AAS.

Caution

· The TAS is set at the factory and must

not be adjusted. Any adjustment will

negatively effect the engine performance.

Specification

650--750 (700 ±50)rpm

F3

5. Set the TEST PID to OFF using WDS or

XME3908W006

equivalent.

6. Disconnect the SSTs (WDS or equivalent)

End Of Sie

IDLE-UP SPEED INSPECTION

Z4F410802000W04

Using the SSTs (WDS or equivalent)

1. Perform "ENGINE TUNE-UP PREPARATION".

2. Verify that the idle speed is normal. (See F331 IDLE SPEED ADJUSTMENT.)

3. Verify that the RPM PID is within the specification using the SSTs (WDS or equivalent).

· If not as specified with all load conditions, inspect the IAC valve.

· If not as specified with some load condition, inspect the related input switches, harnesses, and connectors.

Specification

Idle-up speed (rpm) *1

Load condition Range N (ATX)

Range D (ATX)

/ Neutral (MTX)

650--750

600--700

No load

(700±50)

(650±50)

650--750

600--700

E/L ON *2

(700±50)

(650±50)

650--750

700--800

P/S operating *3

(700±50)

(750±50)

700--800

A/C ON *4

(750±50)

*1

: Excludes temporary idle speed drop just after the electrical loads (E/L) are turned on.

*2

: Headlight is on, blower control switch is above 1st, cooling fan is operating, rear window defroster is on.

*3

: Steering wheel is fully turned.

*4

: A/C switch and blower control switch are on.

End Of Sie

F331

INTAKE-AIR SYSTEM

INTAKE-AIR SYSTEM

VACUUM HOSE ROUTING DIAGRAM (FS)

Z4F411020030W01

Y3A4110N001

End Of Sie

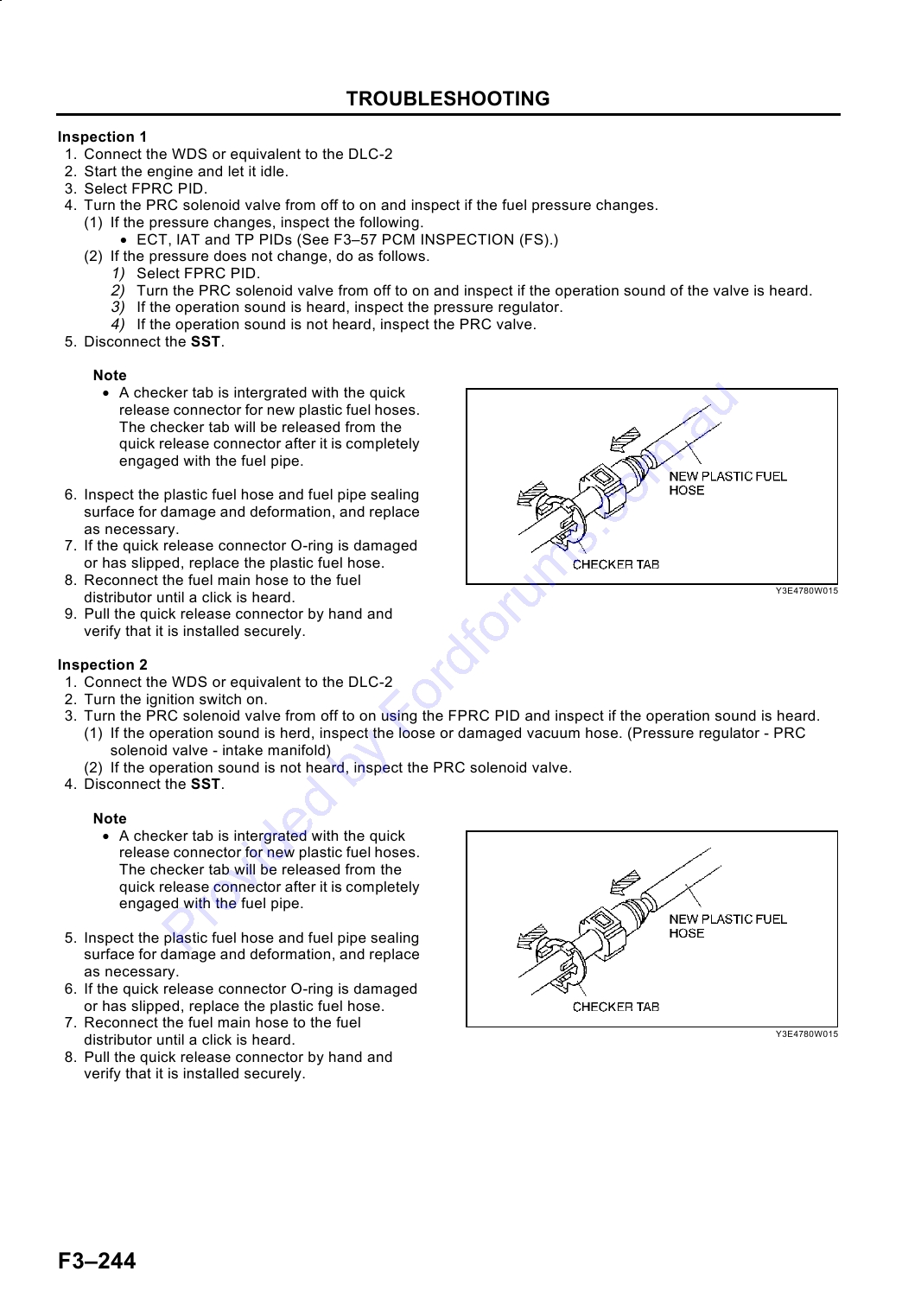

IDLE AIR CONTROL (IAC) VALVE INSPECTION (FS)

Z4F411020661W01

Resistance Inspection

Note

· Perform the following test only as directed.

1. Carry out the "Idle Air Control (IAC) Inspection". (See F3241 Idle Air Control (IAC) Inspection.)

· If not as specified, perform the further inspection for the IAC valve.

2. Disconnect the battery negative cable.

3. Disconnect the IAC valve connector.

4. Measure the resistance between the IAC valve

terminals using an ohmmeter.

· If not as specified, replace the IAC valve.

· If as specified, but PID value failed, carry out

the "Circuit Open/Short Inspection".

-- If there is an open or short circuit, repair

or replace wiring harnesses.

-- If there is no open or short circuit, replace

IAC valve.

Resistance

7.7--9.3 ohms [23 °C {73 °F}]

Z3U0113W997

F332

INTAKE-AIR SYSTEM

Circuit Open/Short Inspection

1. Disconnect the PCM connector.

2. Inspect for an open or short circuit in the following wiring harnesses by probing the applicable sensor and PCM

terminals with ohmmeter leads.

Open circuit

· Power circuit (IAC valve connector terminal A and PCM connector terminal 2P)

· GND circuit (IAC valve connector terminal B and PCM connector terminal 2Q)

Short circuit

· Power circuit (IAC valve connector terminal A and PCM connector terminal 2P to GND)

· GND circuit (IAC valve connector terminal B and PCM connector terminal 2Q to GND)

3. Reconnect the IAC valve connector.

4. Reconnect the battery negative cable.

End Of Sie

VARIABLE INERTIA CHARGING SYSTEM (VICS) SOLENOID VALVE INSPECTION (FS)

Z4F411018740W01

Airflow Inspection

Note

· Perform the following inspection only when directed.

F3

1. Carry out the "VICS Operation Inspection". (See F3242 VICS Operation Inspection.)

· If not as specified, perform the further inspection for the VICS solenoid valve.

2. Disconnect the negative battery cable.

3. Remove the VICS solenoid valve.

4. Inspect for airflow between each port under the

following condition.

· If not as specified, replace the VICS solenoid

valve.

· If as specified, inspect the vacuum hose for

improper routing, kinks, or leakage.

-- If not as specified, inspect the vacuum

hose for improper routing, perform "VICS

solenoid valve circuit open/short

inspection".

Y3E4112W099

Y3E4110W002

F333

INTAKE-AIR SYSTEM

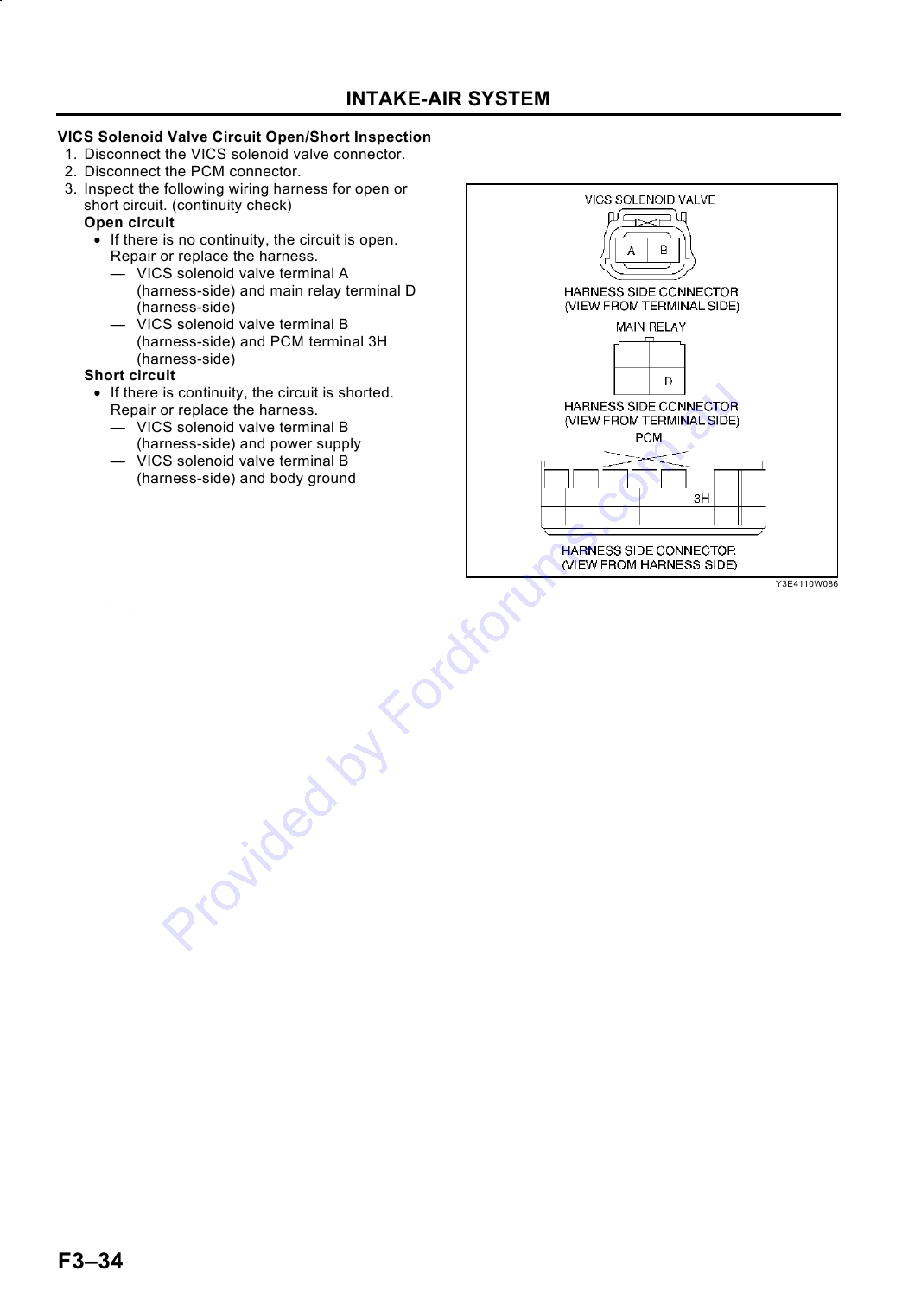

VICS Solenoid Valve Circuit Open/Short Inspection

1. Disconnect the VICS solenoid valve connector.

2. Disconnect the PCM connector.

3. Inspect the following wiring harness for open or

short circuit. (continuity check)

Open circuit

· If there is no continuity, the circuit is open.

Repair or replace the harness.

-- VICS solenoid valve terminal A

(harness-side) and main relay terminal D

(harness-side)

-- VICS solenoid valve terminal B

(harness-side) and PCM terminal 3H

(harness-side)

Short circuit

· If there is continuity, the circuit is shorted.

Repair or replace the harness.

-- VICS solenoid valve terminal B

(harness-side) and power supply

-- VICS solenoid valve terminal B

(harness-side) and body ground

Y3E4110W086

End Of Sie

F334

FUEL SYSTEM

FUEL SYSTEM

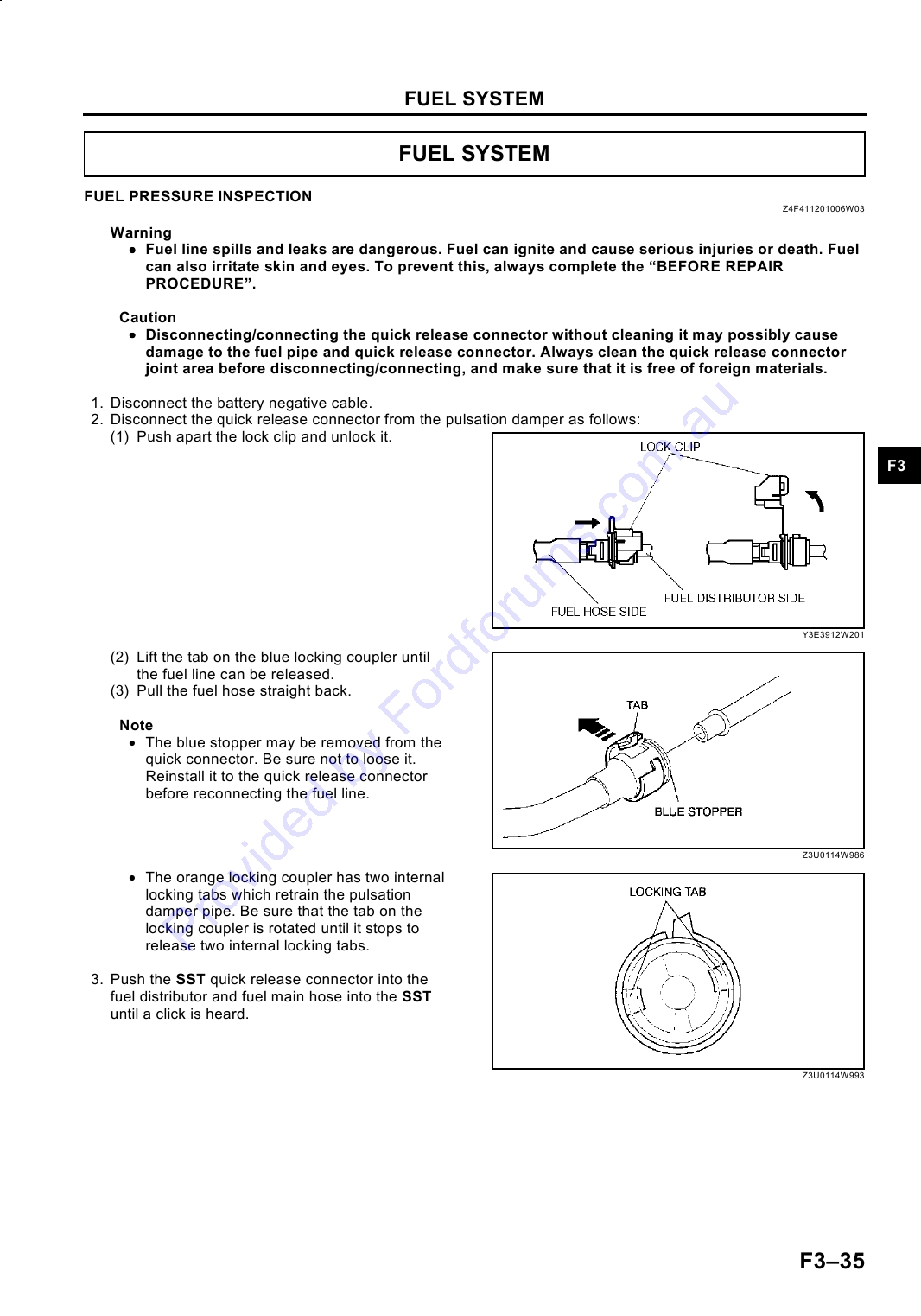

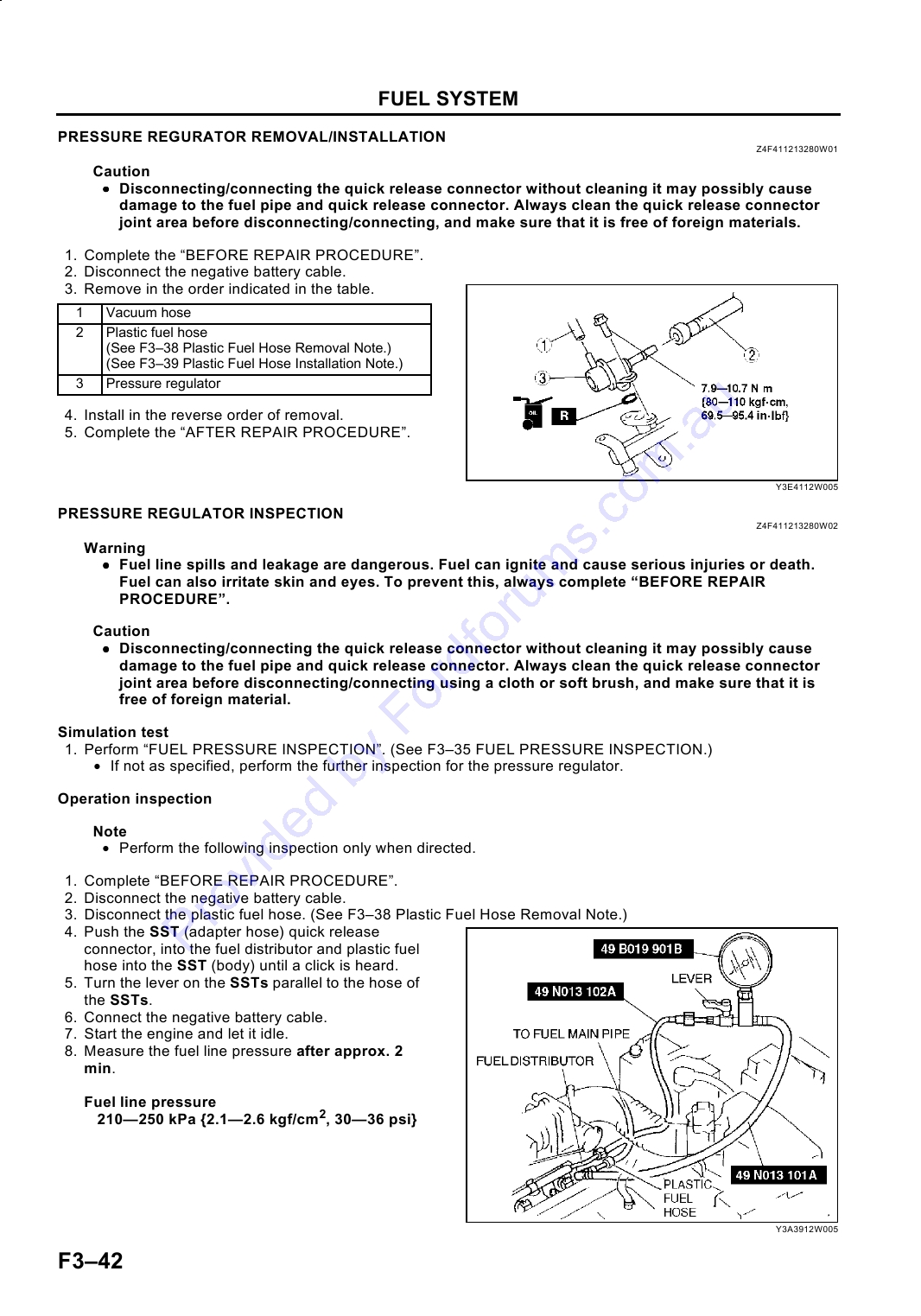

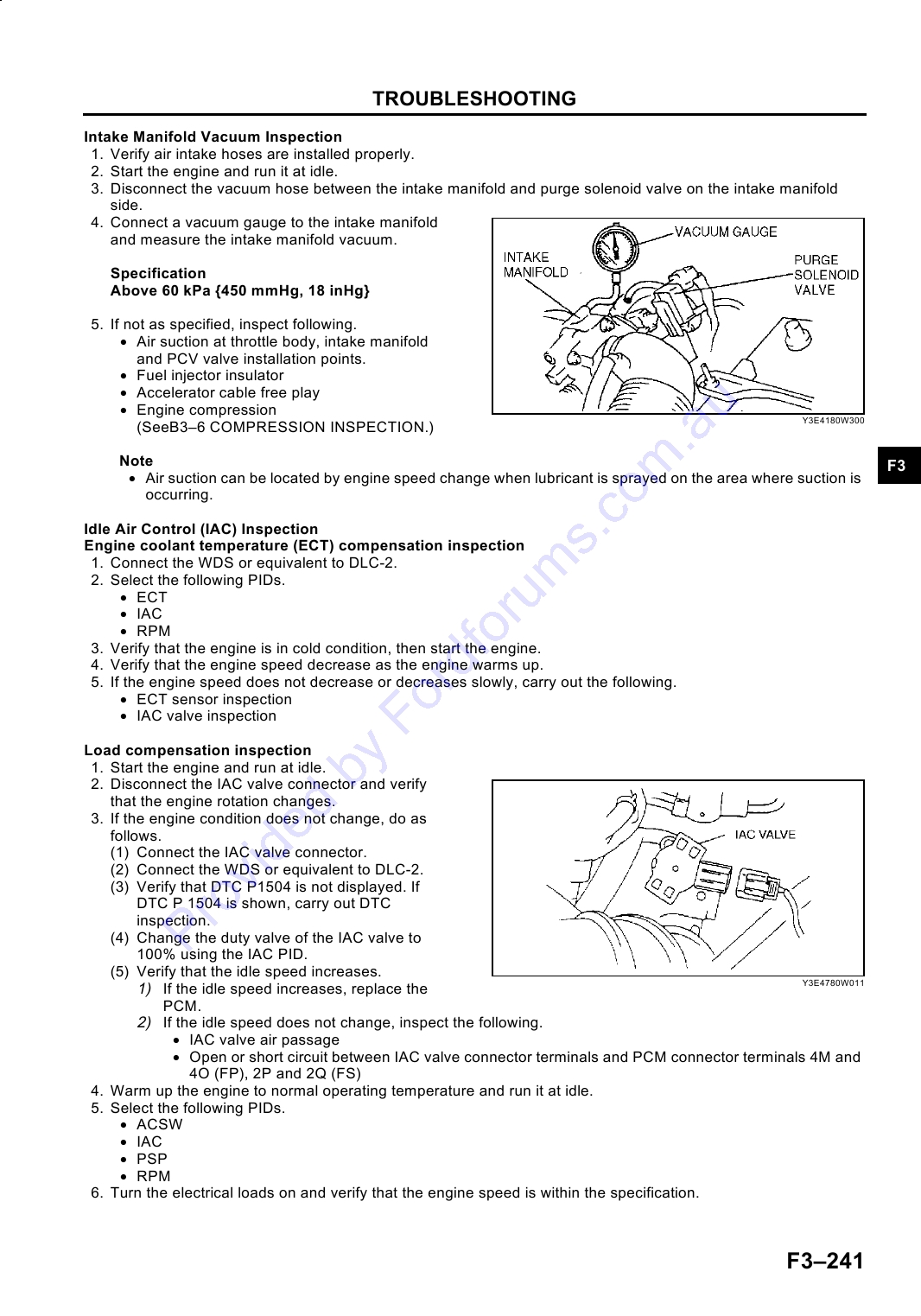

FUEL PRESSURE INSPECTION

Z4F411201006W03

Warning

· Fuel line spills and leaks are dangerous. Fuel can ignite and cause serious injuries or death. Fuel

can also irritate skin and eyes. To prevent this, always complete the "BEFORE REPAIR

PROCEDURE".

Caution

· Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting, and make sure that it is free of foreign materials.

1. Disconnect the battery negative cable.

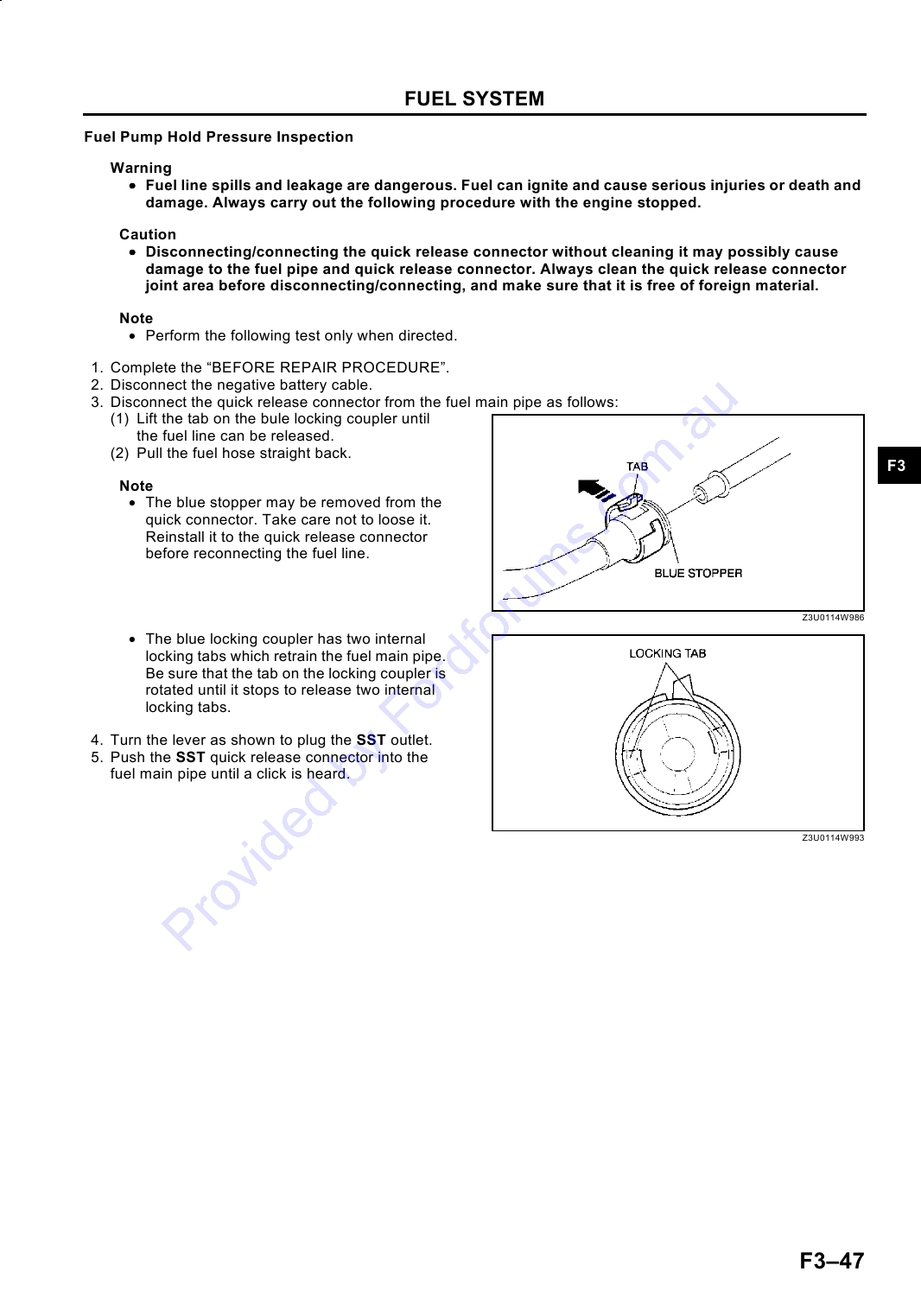

2. Disconnect the quick release connector from the pulsation damper as follows:

(1) Push apart the lock clip and unlock it.

F3

Y3E3912W201

(2) Lift the tab on the blue locking coupler until

the fuel line can be released.

(3) Pull the fuel hose straight back.

Note

· The blue stopper may be removed from the

quick connector. Be sure not to loose it.

Reinstall it to the quick release connector

before reconnecting the fuel line.

Z3U0114W986

· The orange locking coupler has two internal

locking tabs which retrain the pulsation

damper pipe. Be sure that the tab on the

locking coupler is rotated until it stops to

release two internal locking tabs.

3. Push the SST quick release connector into the

fuel distributor and fuel main hose into the SST

until a click is heard.

Z3U0114W993

F335

FUEL SYSTEM

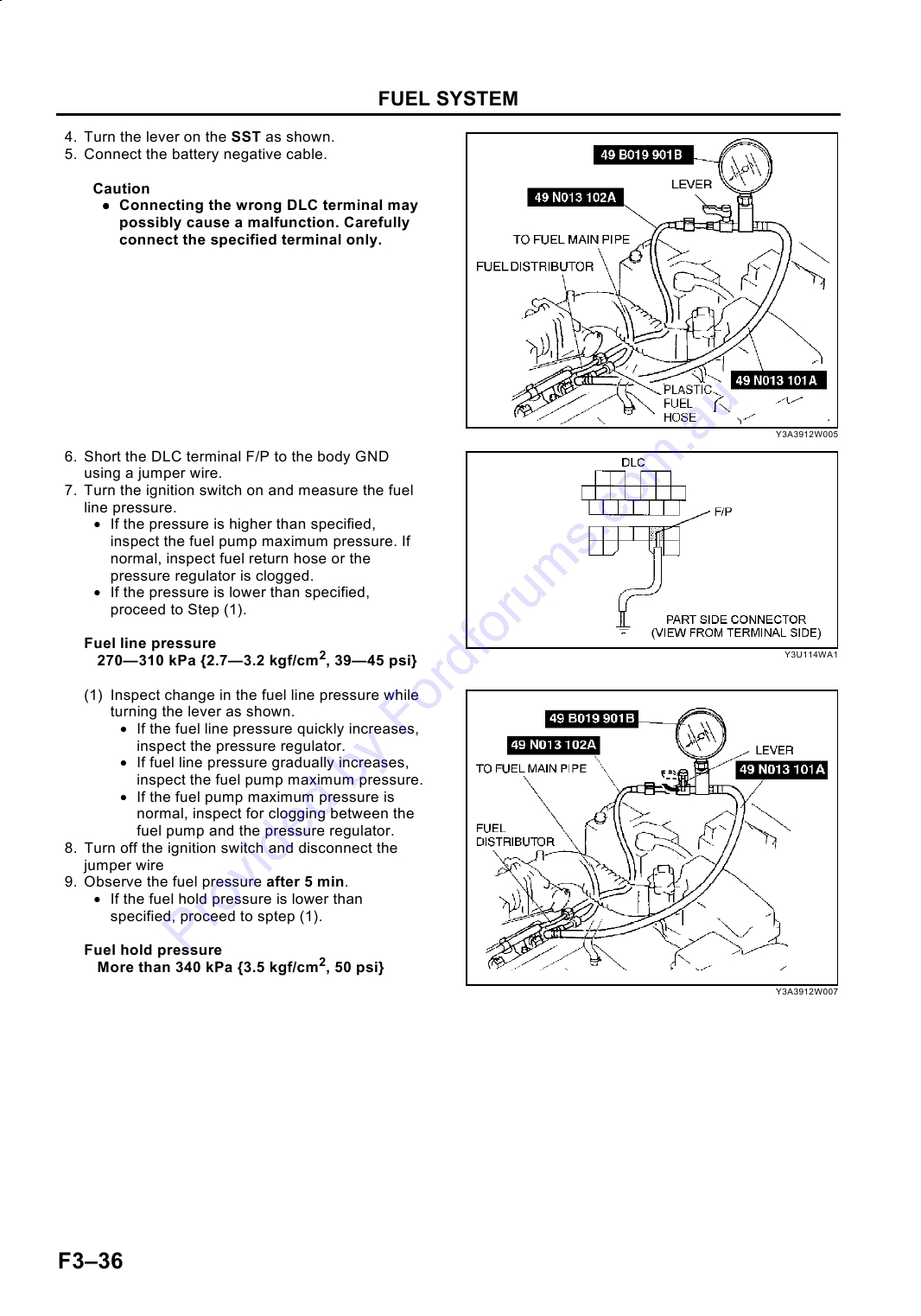

4. Turn the lever on the SST as shown.

5. Connect the battery negative cable.

Caution

· Connecting the wrong DLC terminal may

possibly cause a malfunction. Carefully

connect the specified terminal only.

Y3A3912W005

6. Short the DLC terminal F/P to the body GND

using a jumper wire.

7. Turn the ignition switch on and measure the fuel

line pressure.

· If the pressure is higher than specified,

inspect the fuel pump maximum pressure. If

normal, inspect fuel return hose or the

pressure regulator is clogged.

· If the pressure is lower than specified,

proceed to Step (1).

Fuel line pressure

270--310 kPa {2.7--3.2 kgf/cm2, 39--45 psi}

Y3U114WA1

(1) Inspect change in the fuel line pressure while

turning the lever as shown.

· If the fuel line pressure quickly increases,

inspect the pressure regulator.

· If fuel line pressure gradually increases,

inspect the fuel pump maximum pressure.

· If the fuel pump maximum pressure is

normal, inspect for clogging between the

fuel pump and the pressure regulator.

8. Turn off the ignition switch and disconnect the

jumper wire

9. Observe the fuel pressure after 5 min.

· If the fuel hold pressure is lower than

specified, proceed to sptep (1).

Fuel hold pressure

More than 340 kPa {3.5 kgf/cm2, 50 psi}

Y3A3912W007

F336

FUEL SYSTEM

(1) Inspect changes in the fule line pressure

while turning the lever as shown.

· If the fuel line pressure holds, replace the

pressure regulator. (See F337 FUEL

INJECTOR REMOVAL/INSTALLATION.)

· If the fuel line pressure does not hold,

inspect the fuel leaks from the fuel line

and the fuel injector.

10. Disconnect the SST.

Y3A3912W007

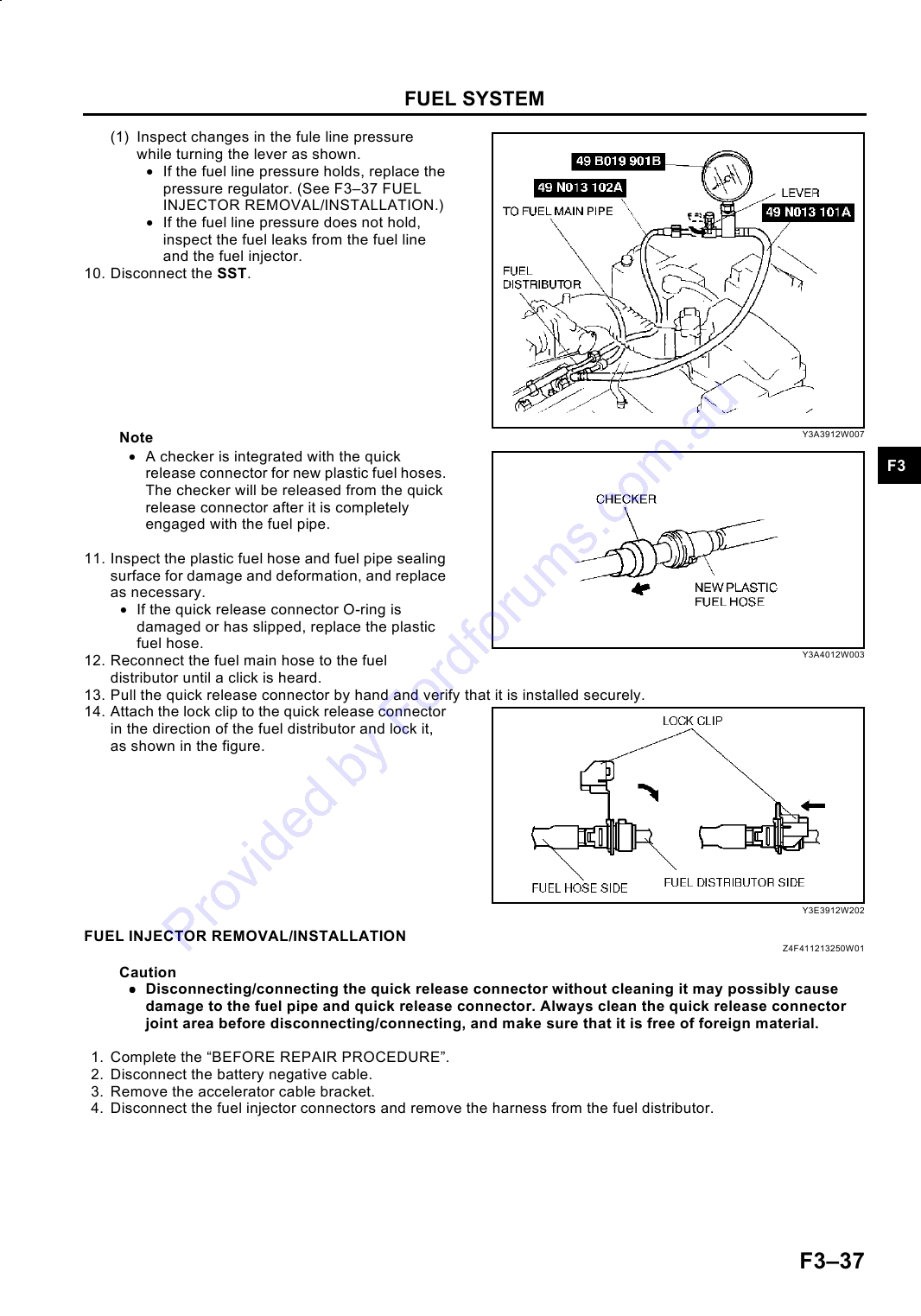

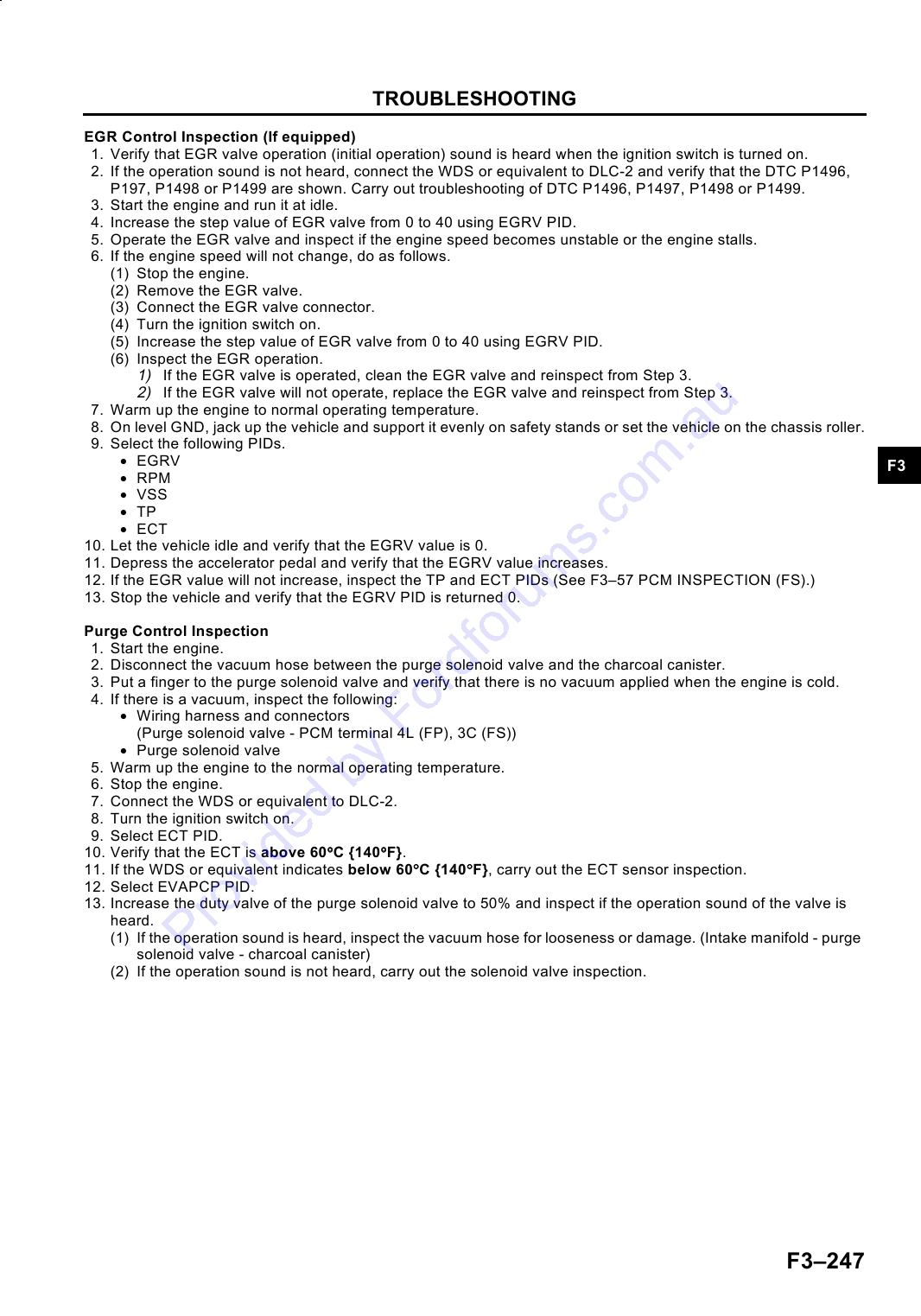

Note

· A checker is integrated with the quick

F3

release connector for new plastic fuel hoses.

The checker will be released from the quick

release connector after it is completely

engaged with the fuel pipe.

11. Inspect the plastic fuel hose and fuel pipe sealing

surface for damage and deformation, and replace

as necessary.

· If the quick release connector O-ring is

damaged or has slipped, replace the plastic

fuel hose.

Y3A4012W003

12. Reconnect the fuel main hose to the fuel

distributor until a click is heard.

13. Pull the quick release connector by hand and verify that it is installed securely.

14. Attach the lock clip to the quick release connector

in the direction of the fuel distributor and lock it,

as shown in the figure.

Y3E3912W202

End Of Sie

FUEL INJECTOR REMOVAL/INSTALLATION

Z4F411213250W01

Caution

· Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting, and make sure that it is free of foreign material.

1.

Complete the "BEFORE REPAIR PROCEDURE".

2.

Disconnect the battery negative cable.

3.

Remove the accelerator cable bracket.

4.

Disconnect the fuel injector connectors and remove the harness from the fuel distributor.

F337

FUEL SYSTEM

5. Remove in the order indicated in the table.

1

Plastic fuel hose

(See F338 Plastic Fuel Hose Removal Note.)

(See F339 Plastic Fuel Hose Installation Note.)

2

Vacuum hose

3

Fuel distributor

4

Fuel distributor insulator

5

Fuel injector insulator

6

Fuel injector

(See F339 Fuel Injector Installation Note.)

7

Grommet

8

Pulsation damper

6. Install in the reverse order of removal.

7. Complete the "AFTER REPAIR PROCEDURE".

Y3A4110W001

Plastic Fuel Hose Removal Note

Caution

· The quick release connector may be damaged when the tab is turned overly. Do not turn the tab

over the stopper.

1. Disconnect the quick release connector from the pulsation damper as follows:

(1) Push apart the lock clip and unlock it.

Y3E3912W201

(2) Lift the tab on the blue locking coupler until

the fuel line can be released.

(3) Pull the fuel hose straight back.

Note

· The blue stopper may be removed from the

quick connector. Take care not to loose it.

Reinstall it to the quick release connector

before reconnecting the fuel line.

Z3U0114W986

F338

FUEL SYSTEM

· The orange locking coupler has two internal

locking tabs which retrain the pulsation

damper pipe. Be sure that the tab on the

locking coupler is rotated until it stops to

release two internal locking tabs.

2. Cover the disconnected quick release connector

and pulsation damper with vinyl sheet or the like

to prevent it from being scratched or

contaminated with foreign materials.

Z3U0114W993

Plastic Fuel Hose Installation Note

1. Inspect the plastic fuel hose and pulsation damper sealing surface for damage and deformation, and replace as

necessary.

· If the quick release connector O-ring is damaged or has slipped, replace the plastic fuel hose.

2. Apply a small amount of clean engine oil to the sealing surface of the pulsation damper.

3. Push the quick release connector straight into the pulsation damper until a click is heard.

4. Lightly pull and push the quick release connector a few times by hand and verify that it can move 2.0--3.0 mm

F3

{0.08--0.11 in} and it is connected securely.

· If quick release connector does not move at all, verify that O-ring is not damaged and slipped, and

reconnect the quick release connector.

5. Attach the lock clip to the quick release connector

in the direction of the fuel distributor and lock it,

as shown in the figure.

Y3E3912W202

Fuel Injector Installation Note

1. Install each fuel injector as indicated in the table.

Cylinder number

Fuel injector body color

No.1, No.2 cylinder

Green

No.3, No.4 cylinder

Purple

2. Use new fuel injector O-rings.

3. Apply a small amount of engine oil to the O-rings and install them into the fuel distributor.

4. Verify that the O-rings and the fuel injector sealing surfaces are free of foreign material. Clean with gasoline if

necessary.

5. Align the fuel injector notch with the fuel

distributor and install the fuel injectors in the fuel

distributor with light twisting motion so that the O-

rings will not be folded.

X3U114WC6

End Of Sie

F339

FUEL SYSTEM

FUEL INJECTOR INSPECTION (FS)

Z4F411213250W02

Simulation Test

1. Carry out the "Fuel Injector Operation Inspection". (See F3245 Fuel Injector Operation Inspection.)

· If not as specified, perform the further inspection for the fuel injectors.

Resistance Inspection

Note

· Perform the following test only when directed.

1.

Turn the ignition switch off.

2.

Disconnect the battery negative cable.

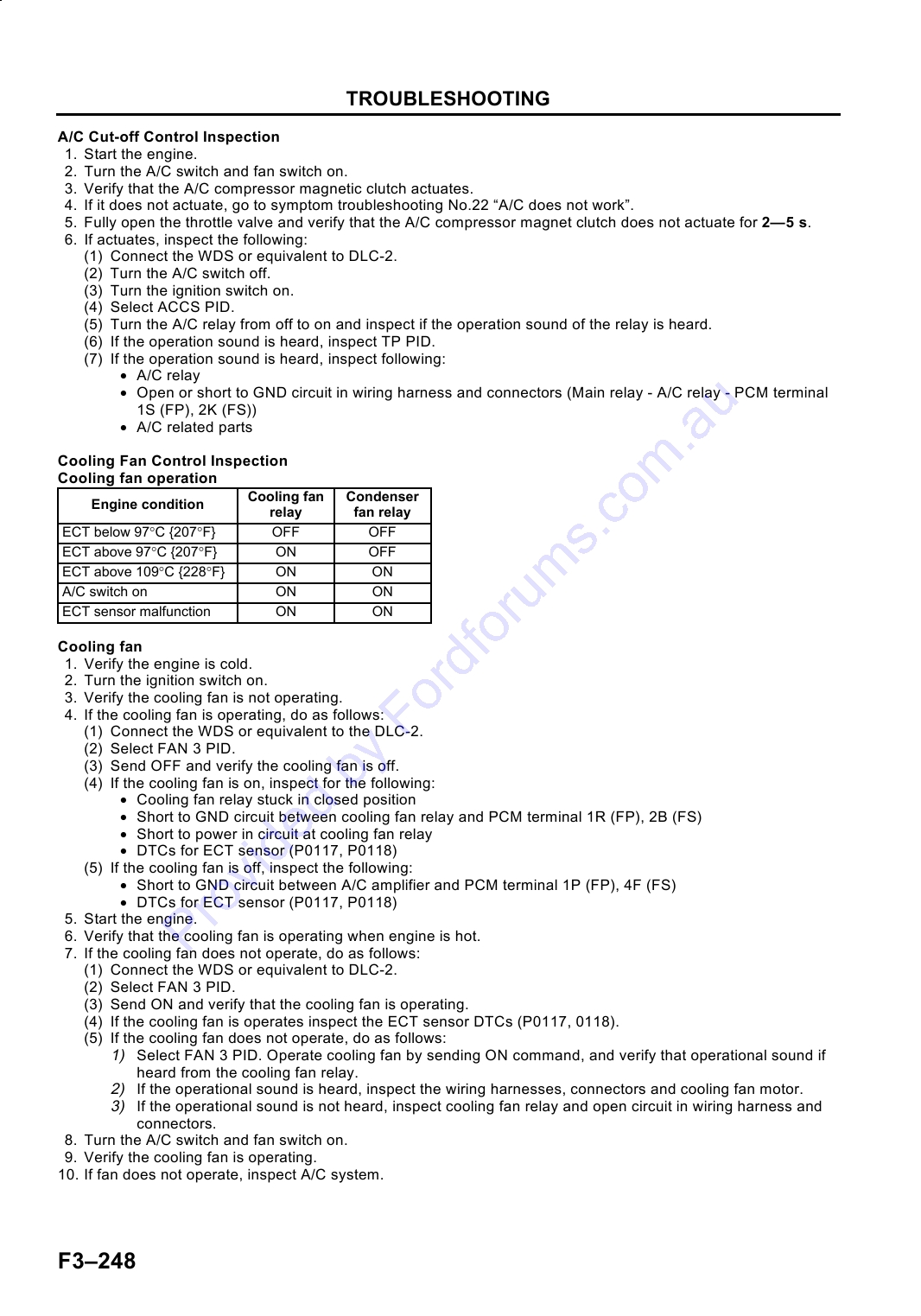

3.